Many people would argue that, with the same displacement, a small-block Chevrolet will produce less power than a big-block Chevrolet. Others might claim that the small-block's weight advantage cancels any power benefits a big-block might offer. One afternoon, while discussing the merits of each, we posed the question, "Which one is really better?" Naturally, a challenge ensued. We decided to build one of each, making their configurations as similar as possible, and then test them head to head on the dynamometer and at the dragstrip.

Most engine builders agree that a small-block is less expensive to build than a big-block. Therefore, we decided to give the rat a cost handicap right out of the gate. We estimated that the big-block would cost about $1,000 more, so we projected $4,500 for it and $3,500 (or less) for the small-block.

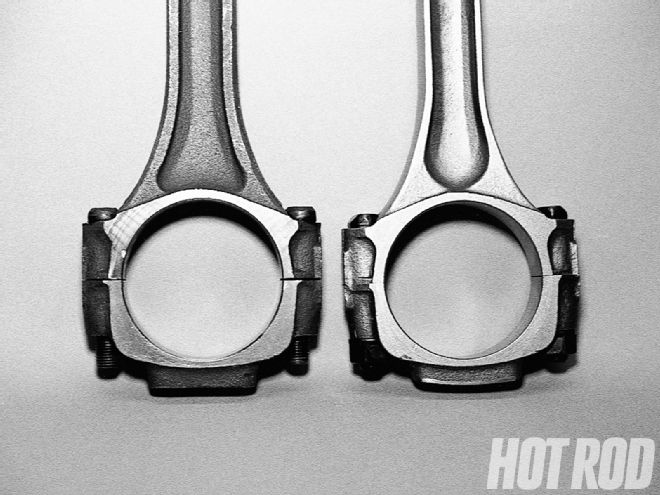

Additional material makes the finished HD forged truck connecting rod (right) that was used in our big-block much stronger than the standard one (left).

Additional material makes the finished HD forged truck connecting rod (right) that was used in our big-block much stronger than the standard one (left).

We referenced the casting number on the block and determined that it was actually a 402-produced between 1968 and 1972-so the cylinder bores would only need a 0.030-inch overbore to attain the 408ci goal. The forged 396 crank was ground to 0.020 inch undersize and polished. Then the HD connecting rods were resized, balanced, and bushed for full-floating wristpins. We used ARP 3/8-inch Wav-Loc rod bolts, and to save some cash, we polished the rods ourselves and then had TBS shot-peen them. We chose forged Federal-Mogul OEM replacement pistons that were 0.060 inch larger than stock. These forgings feature a large 43.1cc hollow dome design, and the 0.020-inch deck height we specified would yield a mechanical compression ratio of 9.6:1.

Since we were bound to a flat-tappet hydraulic camshaft, we researched Comp Cams' new Xtreme Energy line. After speaking with Comp's engineers, we went with the 284 series because the small-block and big-block cams have the same lobes. The only difference between the camshafts is lift, and that's due to different rocker arm ratios. Comp Cams also supplied lifters, pushrods, guide plates, a timing chain, and dual springs with steel retainers. We complemented the assembly with Harland Sharp's 1.8:1 aluminum roller rockers.

Since both engines share the same stroke, the rod length is the variable. The small-block rod (left) is 5.56 inches center to center, yielding a rod-to-stroke ratio of 1.48:1. The big-block's rod measures 6.135 inches, for a 1.63:1 ratio.

Since both engines share the same stroke, the rod length is the variable. The small-block rod (left) is 5.56 inches center to center, yielding a rod-to-stroke ratio of 1.48:1. The big-block's rod measures 6.135 inches, for a 1.63:1 ratio.

We buttoned up the lower end of the big-block with a six-quart Moroso pan, a windage tray, and a crank scraper. The engine is lubed by a Moroso HV oil pump with the pickup welded in place.

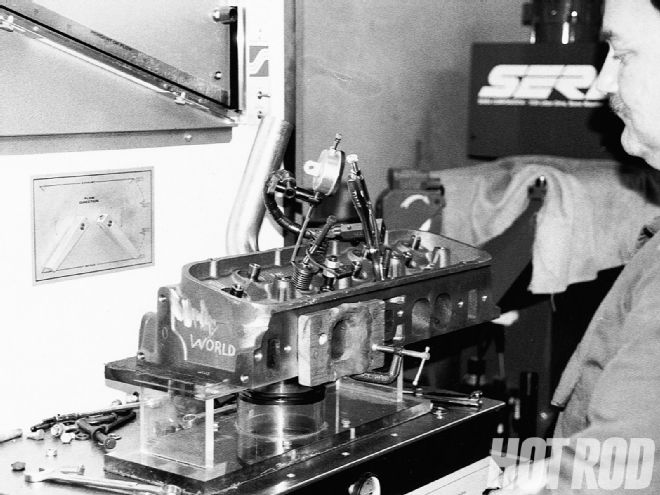

Moving topside, the big-block has Merlin cast-iron, oval-port cylinder heads from World Products (WP). When designing these castings, WP improved the combustion chamber design and opened them up to 119cc. The ports were reworked to provide increased airflow without the usual decrease in low-speed torque (see the "More Power" sidebar). SI Industries supplied 2.19-/1.88-inch stainless-steel valves and 10-degree locks. The 6 1/4-inch-diameter Fluidampr is small and light (weighing just 9 pounds) but requires an adjustable timing pointer like the one we got from Tavia.

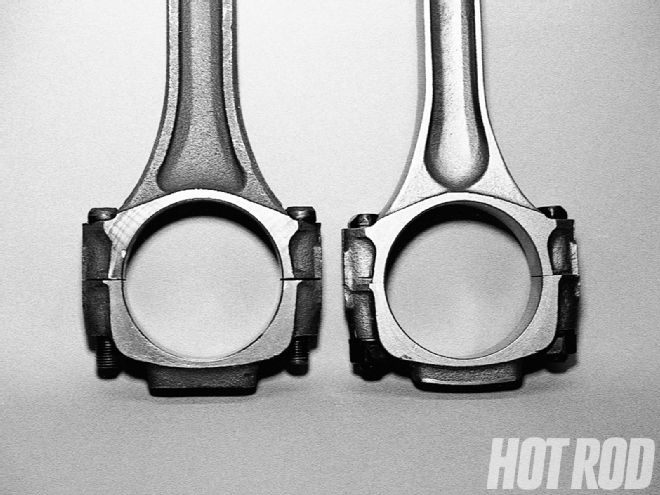

With a convoluted wheel (PN 854123) from Standard Abrasives and a bench grinder, we deburred the pistons and valve springs for both engines. Standard Abrasives also supplied the cartridge rolls and unitized wheel (PN 834105) we used to polish the connecting rods and port the heads.

With a convoluted wheel (PN 854123) from Standard Abrasives and a bench grinder, we deburred the pistons and valve springs for both engines. Standard Abrasives also supplied the cartridge rolls and unitized wheel (PN 834105) we used to polish the connecting rods and port the heads.

The World Products Sportsman II iron castings were fitted with 2.05-inch intake valves and 1.6-inch exhaust valves, springs, locks, and steel retainers. Prior to the engine assembly, we verified that the piston height was 0.020 inch below deck. The small-block used a 10cc dished piston, 72cc combustion chambers, and the 11.6cc ROL head gasket; its mechanical compression ratio was 9.6:1. An Edelbrock Performer RPM intake manifold (PN 7101) went on top.

Both the small-block and the big-block were equipped with a Stage II Racepak 750-cfm Holley built by the Carb Shop specifically for this test. MSD supplied the billet distributor, 8.5mm wires, and all other ignition components for the two. In addition, both used ROL gaskets, fasteners furnished by ARP, and Weiand Team G water pumps.

After the break-in period, we used Mobil 1 synthetic motor oil (0W-30W) and filters designed to withstand 600 psi. According to Mobil, the filter's synthetic fibers trap 95 percent of all contaminants.

After the break-in period, we used Mobil 1 synthetic motor oil (0W-30W) and filters designed to withstand 600 psi. According to Mobil, the filter's synthetic fibers trap 95 percent of all contaminants.

The motor sounded good, so Baechtel set it at 3,500 rpm and applied load. The test began at 3,100 rpm, and the small-block quickly revved to its 6,000 rpm redline, making 412 hp and 430 lb-ft of torque. Decent power for the first pull, but there was more to be had.

We made another pull to establish a baseline. Then on the third pull we tried a Comp Cams 1-inch-thick four-hole carb spacer. That increased top-end power by 2 hp. But something wasn't right. We removed the valve covers and discovered that a rocker arm was looser than it should have been.

We swapped parts throughout the day, trying other carb spacers, rocker arm ratios, timing, and jetting. Our combinations of different carbs and intake manifolds yielded mixed results. The small-block made its best numbers on the last pull with the Performer RPM intake, 72/82 jets, 37 degrees total timing, a 1.6:1 rocker arm ratio on the corner cylinders and 1.5:1 rockers on the rest, and a 1-inch open carb spacer. Peak power was 423 hp at 5,700 rpm while peak torque was 443.3 lb-ft at 4,600 rpm. Down low, though, the small-block sparkled, making more than 400 lb-ft from 3,100 to 5,500 rpm.

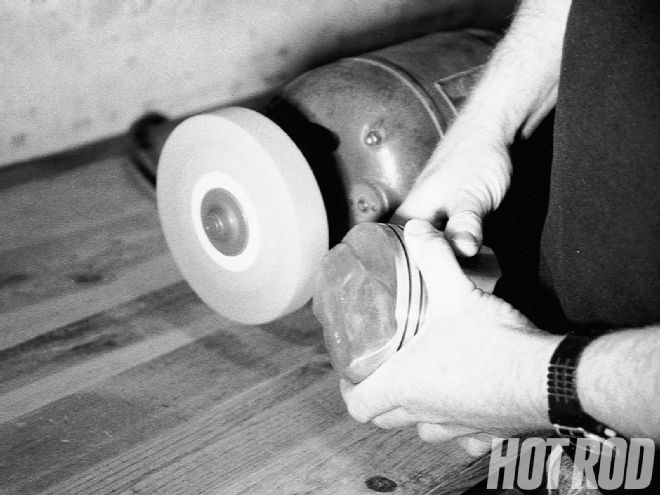

The combustion chamber walls of the Merlin big-block heads were opened up around the intake valve to match the head gasket, thereby increasing airflow and decreasing turbulence. We also ground all sharp areas smooth and polished the chambers.

The combustion chamber walls of the Merlin big-block heads were opened up around the intake valve to match the head gasket, thereby increasing airflow and decreasing turbulence. We also ground all sharp areas smooth and polished the chambers.

We made many more pulls, all the while swapping rocker arm ratios, jets, and timing. Output eventually rose to 440 lb-ft and 448 hp. Up to this point, we had been running a single-plane intake on the big-block because that's what we felt would work best with the camshaft and cylinder heads. But when we bolted on a dual-plane Edelbrock Performer RPM, we found our match. The engine responded with a stout 445 lb-ft and 459 hp. With 74/78 jets, 1.8:1 rockers, 41 degrees total timing, #13 Autolite spark plugs, and a 1-inch open carb spacer, our best rat power was 465 lb-ft at 4,600 rpm (same rpm as the small-block) and 464 hp at 5,400 rpm.

McKenzie's Cylinder Heads flowed both sets of castings.

McKenzie's Cylinder Heads flowed both sets of castings.

We burned more than 60 gallons of 92 octane unleaded, made at least 100 dyno pulls, and learned that these engines are much more similar than they are different. After crunching the numbers, we determined we probably could have made more power with a little less cam duration, or perhaps using a cam with single-pattern phasing. We feel the big-block would probably have produced more if we had not ported the cylinder heads, which actually flowed too much air for our small-inch rat. Also, both engines might have responded better with these same cams but with another half-point of static compression. However, that might have prompted detonation, and neither engine rattled on the cheap 92 octane gas we used, even with 45 degrees total timing.

The question remained: Which engine is the better one? Which one will make your car go faster? Will the big-block's power overcome its weight deficit? Or will the lighter, less-powerful small-block triumph? Read on.

We used ARP Assembly Lubricant on all internal engine fasteners and applied ARP Thread Sealer to the head and the water pump bolts to lubricate and seal.

We used ARP Assembly Lubricant on all internal engine fasteners and applied ARP Thread Sealer to the head and the water pump bolts to lubricate and seal.

Our '70 Camaro mule was already prepared for street and strip duty. It was equipped with a B&M TH400 transmission, a 10-inch converter, and a MegaShifter. The chassis was rudimentary: a 12-bolt rear axle with 4.10:1 gears, Moroso posi unit, Strange Engineering C-clip eliminators, fiberglass monoleaf springs, and Lakewood drag shocks on all four corners. The Be-Cool aluminum radiator and a Flex-a-Lite Black Magic electric fan pulling air through the radiator would accommodate both engines with impunity.

Since we couldn't abide fuel starvation, we hooked a Mallory 250 electric fuel pump, regulator (at the carb), and filter to a 16-gallon RCI fuel cell. Tommy Johnson's Motorsports supplied the lightweight Chevy starters. We also used a different Pioneer transmission flexplate on each engine to offset the disparity between the small-block 400 and big-block 402 crankshaft counterweights. The primary exhaust system was another bone of contention-Hedman Hedders supplied 1 3/4-inch by 3-inch HPC coated headers (the same sizes used on the dyno), and we plumbed them through a 3-inch exhaust system with Walker/DynoMax Welded Race Magnum mufflers.

Jeff Smith (left) snugs the spark plugs on the small-block while Westech dyno champ Louie Hammel puts on the kid gloves to help us.

Jeff Smith (left) snugs the spark plugs on the small-block while Westech dyno champ Louie Hammel puts on the kid gloves to help us.

To compensate for L.A.C.R.'s altitude (2,700 feet above sea level), we dropped down a couple of jet sizes to a 70 main and 82 secondary, which yielded the same time and one-half mph more. We moved our shift points to 6,000 rpm, made several more passes, and then leaned the carb out with 68 and 80 jets; timing was set at 37 degrees. In the end, the mouse ran a best of 12.59 at 107.8 mph and posted a 60-foot time of 1.73 seconds. Adjusting for altitude, you get 12.18 seconds at 111.4 mph at sea level. That's fast for a 3,450-pound street car (with driver) on pump gas.

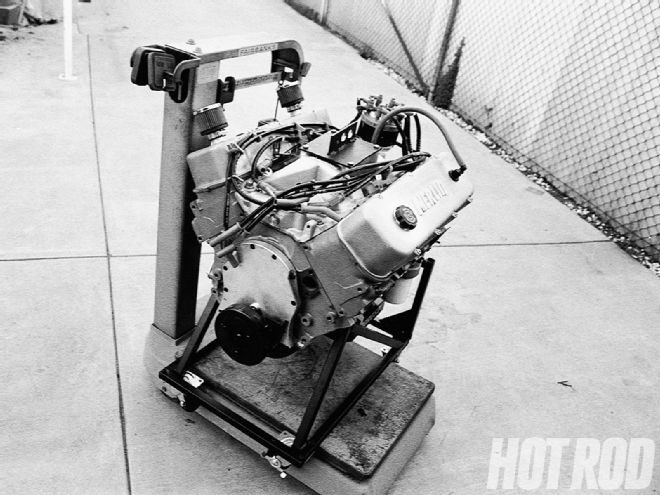

"Tubbo The Big-Block" weighed 610 pounds, 140 more than the mouse. Burp!

"Tubbo The Big-Block" weighed 610 pounds, 140 more than the mouse. Burp!

During the shake-down runs, we could feel the extra torque and were concerned that traction would become the limiting factor. We did a burnout, staged, and left at 2,000 rpm. The Camaro came out hard, spun the tires, and barked 'em through the Second gear shift. The first pass told us all we needed to know: an uncorrected 12.53 at 110.92 mph.

The motor liked leaner jets-running best with 68 primary and 78 secondary jets (six sizes smaller than on the dyno)-and it seemed happiest with 41 degrees of timing (same as on the dyno). But our 60-foot times were slower than the small-block's, indicating that the car wasn't hooking up as well. By leaving the line at idle, we netted the best 60-foot time of 1.77 seconds and the best performance of the day: 12.31 at 110.42 mph. Correcting for altitude, the big-block was worthy of 11.91 seconds at 114.14 mph. We had covered the small-block's butt, but not by much!

408-Inch Small-Block Part Cost Source World Products Sportsman II heads (Head assemblies include valves, valvesprings, locks and retainers, seals, rocker studs, and guide plates.) $896 Jeg's Lunati Street Engine Assembly (Engine assembly includes fully machined block, crank, rods, pistons, bearings, rings, and freeze plugs.) $1,447 Lunati Cam: Comp Cams #XE284-10 $96 Jeg's Lifters: Comp Cams #812-16 $69 Jeg's Valvesprings: Comp Cams #924-16 $100 Jeg's Rocker arms: Harland Sharp #1005 $195 Summit Pushrods: Comp Cams #7812-16 $36 Summit Timing chain: Comp Cams #2100 $40 Summit Head bolts: ARP #134-3601 $46 Jeg's Rod bolts: ARP #134-6402 $39 Jeg's Oil pan: #SUMG3500P $32 Summit Oil pump/pickup: #SES36008002 $55 Summit Oil pump drive: Moroso #22070 $13 Jeg's Gaskets: ROL $100 ROL Damper: stainless steel #SUMB64266 $225 Summit Intake: Performer RPM #7101 $140 Jeg's H2O pump: Weiand #8241 $150 Jeg's Engine Total: $3,679

408-Inch Big-Block Part Cost Source Cam: Comp Cams #XE284-10 $96 Jeg's Lifters: Comp Cams #812-16 $69 Jeg's Valvesprings: Comp Cams #924-16 $100 Jeg's Valve locks: SI VL750 (+0.050 inch) $19 SI Industries Retainers: Comp Cams #744-16 (7 degrees) $48 Comp Cams Rocker arms: Harland Sharp #2002 $220 Summit Pushrods: Comp Cams #7854-16 $48 Summit Timing chain: Comp Cams #3110 $40 Comp Cams Seals: SI #VSS-1711 $16 SI Industries Heads: World Products (bare) $895 World Products Valves: SI 2.19I #1651SG($11.50 each) $92 SI Industries Valves: SI 1.88E #1607SG($12 each) $96 SI Industries Rocker studs: ARP #135-7101 $27 Summit Guide plates: Comp #4806-8 $29 Competition Products Head bolts: ARP #135-3603 $74 Summit Main bolts: ARP #135-5002 $29 Jeg's Rod bolts: ARP #135-6402 $39 Summit Oil pan: Moroso #20403 $206 Jeg's Oil pump: Moroso #22160 $79 Jeg's Pickup: Moroso #24440 $30 Summit Oil pump drive: Moroso #22080 $14 Jeg's Gaskets: ROL $100 ROL Damper: Fluidampr #713282 $280 Summit Pointer: Tavia #02357 $27 Summit Pistons: F/M #2287F $387 Summit Rings: F/M #R-9210 65 $113 Summit Main bearings: F/M #4400 M 20 $30 Summit Rod bearings: F/M #3190CP 20 $37 Summit Cam bearings: F/M #1404 M $23 Summit Freeze plugs: Pioneer #830002 $17 Jeg's Intake: Performer RPM #7161 $170 Summit H2O pump: Weiand #8243 $170 Summit Block: (used) $100 Memory Lane Forged crankshaft: (used) $75 Balance Shop HD truck rods: (used) $40 Burbank Speed Big-block total parts: $3,745

Machine Work Bore and bush rods $85 Balance Shop Rebuild big ends $85 Balance Shop Polish and peen rods $85 Balance Shop Magnaflux rods $20 Balance Shop Tank block $60 Balance Shop Align bore mains $110 Balance Shop Bore and hone block $95 Balance Shop Deck surface $70 Balance Shop Install cam bearings $35 Balance Shop Grind and index crank $40 Balance Shop Balance assy. $95 Balance Shop Big-block machine work total: $780 Big-Block Engine Total: $4,525

Engine Incidentals Part Cost Source Motor mounts: Moroso $19 Summit Starter: Lightweight, high torque $100 Tommy Johnson's Motorsports Carb: Carb Shop Stage II Racepak 750 $750 Summit Flexplates: Pioneer $62 Summit Distributor: MSD #8361 billet with vacuum adv. $175 Summit Cap: MSD #8445 Cap-A-Dapt $37 Summit Coil: MSD #8223 Blaster 3 $30 Summit Wires: MSD 8.5MM Super Conductor $59 Summit Oil: Mobil 1 0W-30 (7 quarts) $28 local auto-parts store

Dyno Test Results RPM Small-Block Big-Block TORQUE HP TORQUE HP 3,100 412 243 377 223 3,300 415 261 406 255 3,500 428 285 424 283 3,700 432 304 428 301 3,900 435 323 448 332 4,100 437 341 452 353 4,300 435 356 451 369 4,500 441 378 461 395 4,700 436 390 462 413 4,900 424 396 451 421 5,100 420 408 448 435 5,300 410 413 451 455 5,500 401 420 441 462 5,700 390 423 395 428 5,900 370 415 378 425

Mouse: Peak torque: 443 at 4,600 rpm Peak horsepower: 423 at 5,700 rpm

Rat: Peak torque: 465 at 4,600 rpm Peak horsepower: 464 at 5,400 rpm

Note that the small-block made more torque up to 3,700 rpm. At that point, the big-block surpassed it, making as much as 50 lb-ft more torque at 5,400 rpm. But check out how rapidly the big-block's torque fell off after 5,500 rpm, whereas the small-block, making less power, upheld its power curve. The big-block dropped 46 lb-ft of torque between 5,500 and 5,700 rpm. The reason for this is unknown-perhaps the engine went into valve float.

Los Angeles County Raceway's 2,700-foot elevation dictates leaner jets to compensate for thinner air. Swapping them was easy with Holley's Quick-Change fuel bowls.

Los Angeles County Raceway's 2,700-foot elevation dictates leaner jets to compensate for thinner air. Swapping them was easy with Holley's Quick-Change fuel bowls.

We hand-worked the big-block stuff for about six hours and increased the flow of the Merlin intake ports by 9 percent and that of the exhausts by 30 percent. More importantly, we elevated the intake-to-exhaust flow ratio from 72 to 86 percent. After eight hours mano a mano with the small-block's Sportsman IIs, we got 9 percent more on the intake side and picked up the exhaust flow by 27 percent. The intake-to-exhaust flow ratio jumped from 67 percent to 78 percent.

Neither set of heads responded well in the lower-lift ranges, however. The Merlin ports dropped 12 percent on the intake side at 0.200-inch valve lift, while the exhaust gained 10 percent. Likewise, the Sportsmans declined at the same lift, with the intake off 9 percent and the exhaust off 2 percent. (The combustion chambers of both sets of heads had been cleaned up to remove sharp edges and eliminate possible hot spots. In addition, a three-angle valve job was performed on each.)

The dyno tests proved that you can port too much. Considering that the engines had similar bores and strokes, and that the small-block made more torque in the 3,100-3,700 rpm range, the lower-cfm flow values of the small-block heads might have contributed to making more power. Conversely, the big-block's lack of low-end torque points to a cylinder head that has too much flow, especially for its relatively small displacement.

Cylinder Head Flow Figures

Lift

Stock

After

porting

Stock

After

porting

S/B

cfm

S/B

cfm

B/B

cfm

B/B

cfm

Intake,

Exhaust

Intake,

Exhaust

Difference

Intake,

Exhaust

Intake,

Exhaust

Difference

0.100

66,

55

65,

50

-2%,

-9%

77,

59

68,

59

12%,

equal

0.200

130,

100

118,

98

-9%,

-2%

152,

114

134,

125

12%,

+10%

0.300

180,

129

171,

136

-5%,

+5%

209,

153

208,

183

+1%,

+20%

0.400

205,

142

213,

167

+4%,

+18%

260,

184

267,

228

+3%,

+24%

0.500

220,

147

240,

181

+9%,

+23%

283,

203

300,

262

+6%,

+29%

0.600

224,

150

245,

190

+9%,

+27%

297,

214

323,

278

+9%,

+30%

Tale of the Tape Block mains: 408-Inch Small-Block 408-Inch Big-Block two-bolt two-bolt Crankshaft: cast Lunati forged GM Connecting rod length (stock): 5.56 inches 6.135 inches Rod to stroke ratio (stock): 1.48:1 1.63:1 Main bearing journal diameter (stock): 2.65 inches 2.75 inches Rod journal diameter (stock): 2.10 inches 2.20 inches Stroke (stock): 3.75 inches 3.76 inches Bore size (finished): 4.165 inches 4.154 inches Piston installed height: 0.020 inch below deck 0.020 inch below deck Piston type: 10cc dish, forged, press-fit 43.1cc dome, forged, floating Compression ratio: 9.6:1 9.6:1 Total engine weight: 470 pounds 610 pounds Cylinder heads: 200cc Sportsman II 270cc oval-port Merlin Combustion chamber volume: 72cc 119cc Valves: 2.05-inch intake/1.6-inch exhaust 2.19-inch intake/1.88-inch exhaust Cam duration (advertised): 284 intake/296 exhaust 284 intake/296 exhaust Cam duration at 0.050 inch: 240 intake/246 exhaust 240 intake/246 exhaust Lobe lift: 0.338-inch intake/0.340-inch exhaust 0.338-inch intake/0.340-inch exhaust Valve lift: 0.541-inch intake/0.544-inch exhaust 0.608-inch intake/0.612-inch exhaust Rocker arm ratio: 1.6:1 1.8:1 Lobe centers: 106 intake/114 exhaust 106 intake/114 exhaust Lobe separation: 110 degrees 110 degrees Rings: single moly single moly Total cost to build: $3,679 $4,525