A cooling system can sometimes be a buzzkill. You drop your badass engine into your badass hot rod, and then you remember you've got to keep it cool. As an afterthought, you order a big aluminum radiator and a set of huge electric fans, and problem solved. The fortunate few will get lucky, but many folks will run into the same situation we had with our big-block '68 Valiant: Overheating still happens when that first long drive on a hot day comes.

When trouble strikes, you do what you always do and rely on the help of knowledgeable friends. And when it comes to friends who know cooling systems, you can't do better than Derale Performance. Why Derale? They don't do just one thing—they handle many of the needs in the fluid path and electrical system of the cooling system. An analogy might be helpful here. If the only tool in your toolbox is a hammer, then you end up trying to fix everything with a hammer. If you call a radiator guy, he'll sell you a radiator. If you call a water pump guy, he'll sell you a water pump. Since we didn't know what the root problem was with our overheating, we called Derale.

They could've blamed our radiator and fan setup for the problem, but after seeing our Valiant in person with its massively overkill aftermarket cooling system, Derale realized the overheating problem did not originate there. The only obvious issue was that our two 13-inch SPAL-sourced fans weren't turning on. Further digging revealed a real eye-opener; both 30-amp fuses that feed current to the two fans were melted inside their rubber holders, and those in turn were baked to a brittle, useless mess. Strangely enough, the fuse filaments themselves were not blown; circuit current was eventually broken when thermal fatigue and vibration fractured the fuse body itself.

Like many aftermarket cooling systems, ours used a temp sensor (thermistor) in the water-pump housing, which toggles a relay that feeds power directly from the battery to the fans. The temp goes up and down, and the relay turns power to the fans on and off. Fuses in the fans' power harness are supposed to protect the fans and wiring, and in our case the 30-amp fuses were properly matched to the 30/50amp relays, which were all supplied by the cooling system manufacturer and installed as directed. All this is standard fare for packaged cooling systems; it's simple, and it works well in a fair amount of applications, but not ours.

All the safety margin in our wiring had been eroded by the fact that a). we had a 657hp big-block, b.) there was intimate proximity of the wiring to major sources of heat, c.) we made frequent long stints in bumper-to-bumper traffic exceeding two hours, and d.) we were operating the vehicle in a desert-like environment most of the year. With that as a backdrop, Derale pointed out that the start-up current spikes placed on the electrical system by the fans were the culprits. The thermistor sensor in the water pump housing was turning the fans on full blast (100 percent) at 195 degrees, and turning them completely off (0 percent) at 175 degrees—meaning we were hitting our wiring with current spikes at or over 50 amps several times a minute while trying to regulate the coolant temperature. As we discovered, fuses don't blow at their rated amperage during transient spikes, only under continuous load. That was too-late news for us.

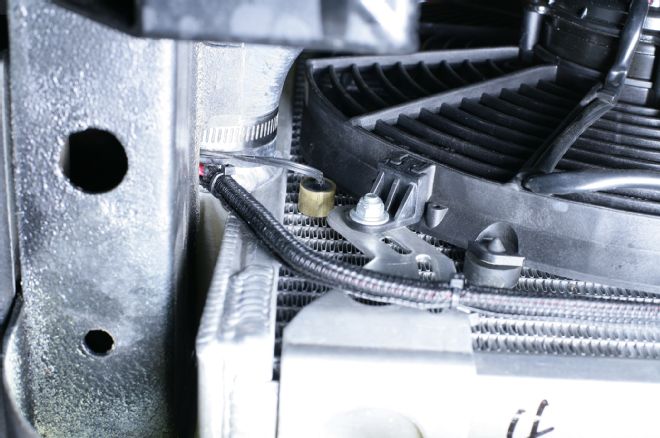

Derale suggested we replace our current thermistor/relay setup with their PWM Fan Controller (PN 16795, street price around $194). This ingenious microprocessor-controlled device can cycle multiple fans on without voltage spikes through what they call Soft Start Technology. (More on that later.) The PWM controller also uses a temperature probe in the cold side of the radiator, not on the engine or water pump. This means the PWM isn't reacting to changes in temp, it's getting ahead of the curve and anticipating the cooling demand before things get too far out of hand. By doing this, the fans rarely need to hump at 100 percent capacity, and that extends the life of your fan motors big-time.

At the heart of the PWM's Soft Start Technology is the pulse-width modulated (PWM) control of the fan circuit. Rather than switching the circuit open in a hard fashion (and causing a transient), the PWM rapidly cycles the circuit on and off in a square-tooth wave form at very high frequency, ramping up the fan speed gradually. Once the fan is on, the PWM adjusts the fan speed dynamically; the higher the temp, the greater the percentage of "on time" for the pulsed DC-circuit wave form. (Note: The PWM does not convert the circuit to alternating current.) There are some other proprietary things going on (like the anti-fly back circuitry protection) that protects the fan's commutation circuitry, but we can't say for sure, and Derale isn't spilling the details of their patent. Suffice it to say it works damn good. The current spikes on our Valiant went down from 50 amps to a max of 23.6 amps—well under the wiring's nominal rating of 30 amps. Our worst-case traffic-jam scenario went from seeing 50-amp spikes (times two fans) every 20 to 30 seconds, to never seeing 24 amps, ever.

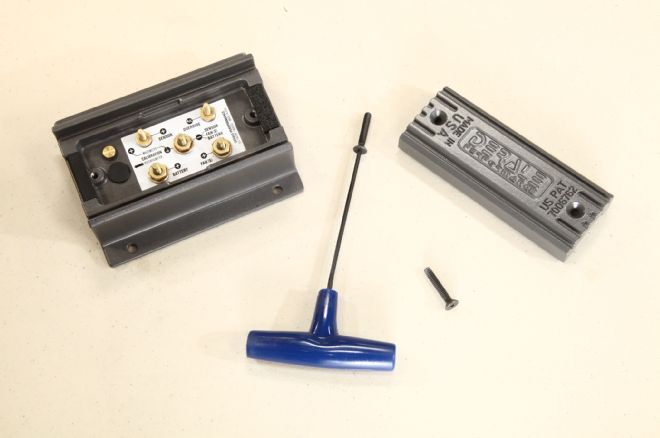

We also liked that the Derale PWM Fan Controller uses a time-delay circuit breaker rather than fuses. Should the current spike too high for some reason (the PWM is rated for multiple fans totaling 65 amps), the circuit breaker intervenes, and resets automatically in about 10 seconds. No more replacing fuses, no more melted wiring, or in our case, no rewiring the fan harness with a new in-line fuse socket. We might also mention that for cars with air conditioning, Derale provides the PWM Fan Controller with a/c override control, which kicks the fans up to 60 percent when commanded via a dedicated input from the A/C system, or a manual override switch. Sharp readers may also ask if the PWM can be customized to work with different thermostats, and the answer is "yes." Derale built in a small potentiometer—accessible under the protective cover plate through a small hole with a thin screwdriver—that allows the user to match the operating range of the PWM to the opening/closing of the thermostat (pre-set from the factory for 180 degrees). It's very slick, it comes in a compact, robust powdercoated die-cast housing, and it's entirely built in the USA.

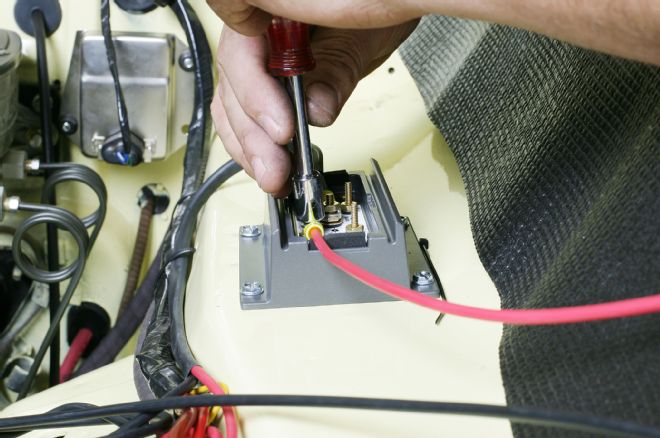

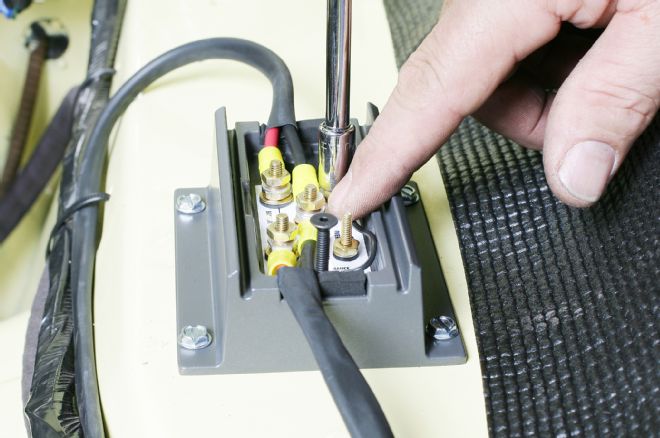

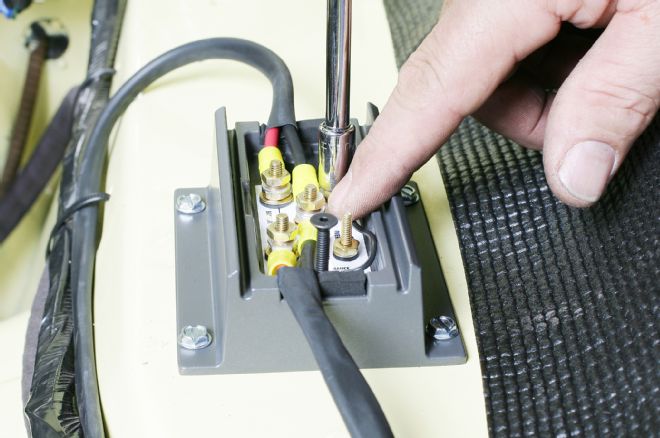

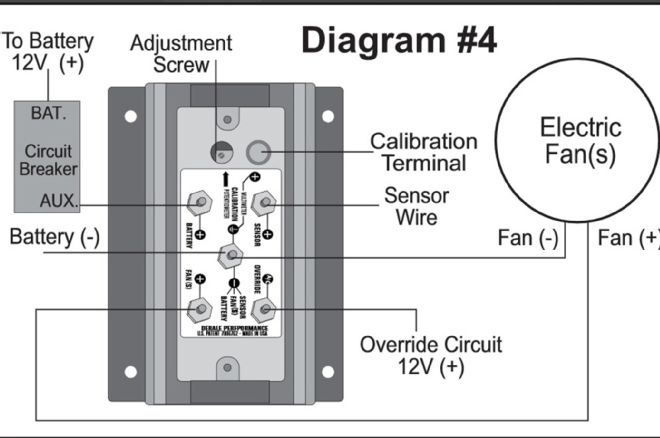

Installing the PWM fan controller is straightforward, thanks to a minimal number of connections (there are five in all, but only four will be used if you don't have a/c), and some clearly written instructions. A sturdy cast lid covers an internal recess with five brass electrical posts. One wire from the positive terminal of the battery feeds the system on one post. Another post (center) is the terminal for two wires, one to the battery negative (ground) and the other to the fan negative (ground) wire(s). A third post sends power to the fan positive wire(s). The fourth post (smaller than the rest as it carries less current) attaches to the Derale-supplied temperature probe. The last post (also a smaller one) is used for the A/C trigger. (We did not use this one.) A time-delayed, thermally protected 50-amp circuit breaker is also included, and must be connected in line between the positive battery power feed and the PWM. You can mount the PWM anywhere; it's tough enough to handle weather and heat, so we put ours on the inner fender. It's an attractive piece of eye candy, so we didn't mind.

Here's a quick rundown of the Derale PWM Fan Controller installation in our big-block– powered '68 Plymouth Valiant.

1. We didn't even know we had a Mopar meltdown until we checked our cooling system fuses. When the temp went up, we found out our fans weren't operating. We checked the fuses to see if they had blown, and they hadn't. Instead, both fuses had melted (arrow) and their fuse terminals were baked to a crisp. The problem: too many high amperage spikes from the fans cycling on and off. We were extremely lucky this is all the damage we suffered.

2. The Derale PWM Fan Controller is built like a tank. A die-cast body houses the microprocessor and attendant electronics, a die-cast lid covers the electrical connections for the power, fans, temp sensor input, ground, and A/C override. A small potentiometer allows the user to adjust the unit's operation to match the thermostat—which is set from the factory for 180 degrees.

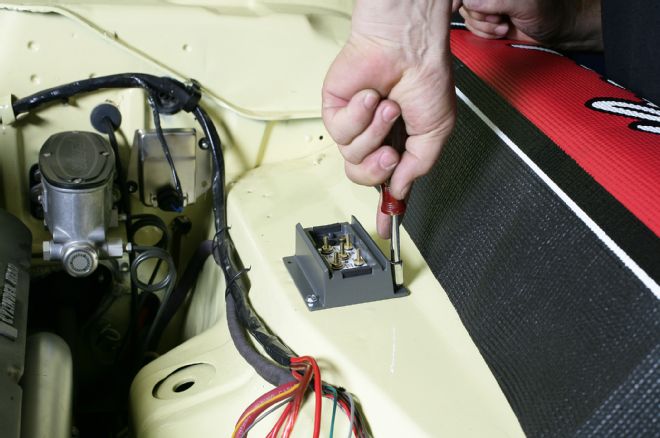

3. Derale recommends the unit be mounted away from extreme sources of heat and close enough to the fans and battery to limit the length of wire runs. The top of the inner fender on our Mopar provided the perfect spot.

4. The PWM comes with 10-gauge AGW wire, which has a 65-amp current capacity—plenty for what needs to be done. Here, the red positive battery lead and the black negative ground lead have been crimped to the loop terminals and screwed to the proper posts on the PWM. We tried to keep a factory-fresh vibe with some OE-style sheathing.

5. The other end of the red battery lead in that last shot gets wired to a time-delay 50-amp circuit breaker. If triggered, this breaker automatically resets once the circuit has sufficiently cooled down. The other wire continues the circuit on to the positive battery terminal.

6. Using another length of 10-gauge AGW wire, crimp a loop connector on and attach it to the positive fan terminal on the PWM. The other end is discretely routed to the fan harness—in our case twin SPAL 13-inch units (PN VA13-AP70/LL-63A).

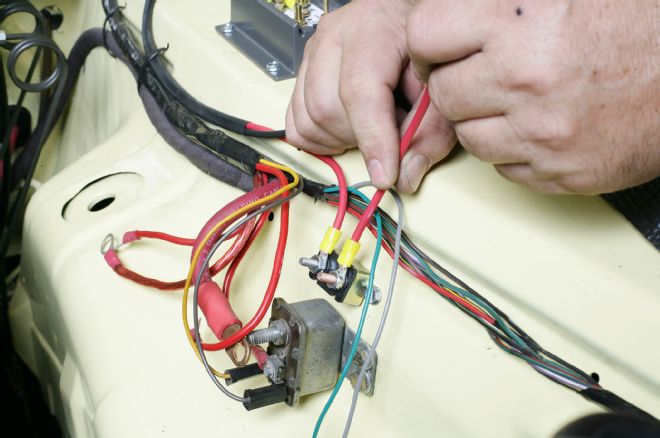

7. We preserved both the male and female AMP 180908 terminals that came with our SPAL fans, splicing the 10-gauge wire into the male end to preserve our ability to disconnect it in the future. Here, the spliced area is being treated to a length of heat-shrink wrap to protect the connection. Note how the single 10-guage feed wire from the PWM has been split to feed the two smaller fan positive wires. The same goes for the black negative (ground) wire.

8. Looking from below, you can see how the Derale temperature probe has been inserted into the radiator near the "cold" outlet that feeds the engine. This is a departure from the common practice of using a thermistor in the water pump housing or intake manifold. This smooths out the temperature swings in the system, making the low and high extremes closer together.

9. The other end of the temperature probe wire gets attached to the PWM on a post specifically for that purpose. The post is one of the two smaller ones, which doesn't have to handle high amperage.

10. Derale specifically states that the negative (ground) connection should go all the way to the battery and not a chassis ground. Doing otherwise can lead to a dirty power signal that can interfere with the microprocessor's output signal. Nevertheless, Derale wanted to test our PWM's operation using a chassis ground, so this filter was attached between the positive and negative leads. You won't need this; we just thought we'd explain why it's here.

11. Here's what the Derale PWM Fan Controller looks like all wired up before the protective cover is screwed on.

12. This diagram is supplied with the PWM Fan Controller, and makes things a lot easier to understand.

13. All wired up, and ready to rock! So far, our twin 13-inch fans are coming on reliably, and haven't produced any wire-melting current spikes. We'll be putting the Valiant through some additional street trials, working our way up to the point where we feel it's safe to drive all day through the desert.