Speaking of factory paints, Dan Widmann's '72 Torino from "The Drive" in the June '08 issue is wearing a gorgeous Lexus hue called Spectra Blue Mica. Russ Stevenson at Gold Coast Custom laid down six coats of the PPG base over light-gray primer to get full coverage then followed with four coats of Glasurit clear. By the way, there are three very similar colors from Lexus; the code you need for this one is 8M6.

Speaking of factory paints, Dan Widmann's '72 Torino from "The Drive" in the June '08 issue is wearing a gorgeous Lexus hue called Spectra Blue Mica. Russ Stevenson at Gold Coast Custom laid down six coats of the PPG base over light-gray primer to get full coverage then followed with four coats of Glasurit clear. By the way, there are three very similar colors from Lexus; the code you need for this one is 8M6.

Nearly every year, and as recently as in the May '08 issue, HOT ROD tells you the basics as well as the latest tips and tricks in paint and bodywork. So by now you should have a pretty good handle on how to get the sheetmetal straight. One thing we haven't covered in more than 20 years is what to paint your hot rod or custom car to make it stand out from the crowd.

Way back, HOT ROD presented bold, new, dynamic custom color schemes to get us back on track, graphically, after the mixed-up miasma of the van-crazed '70s. We started with new designs in candies, pearls, stripes, and flames, emphasizing creative tape layouts, bright candy colors, and blended fades and overlays. But later, we announced a bold graphic attack with heartbeat blips, lightning bolts, and the first splash waves. Airbrush artists were creating things like realistic rips and tears in the late '80s. It was a vibrant, creative time in custom painting.

Unfortunately, it devolved rapidly. Splashes started turning into drips and blobs. Flames and scallops couldn't figure out which way to go. Candies and pearls turned into whole cars painted Day-Glo. Some of those paint jobs were getting downright gaudy and awful. But what was worse, they were incredibly labor intensive, time-consuming, and expensive.

But things have been happening, lots of things-good things. Fortunately, what we've been doing in the last decade is getting back to basics. On any car, but especially ones that have pleasing body shapes to begin with, all you really need for an outstanding, double-take paint job is to get the sheetmetal nice and straight, spray on a slick and smooth coat of paint in any rich color-straight black to Ferrari red to candy gold-then color-sand and rub it out to a mirror-smooth, glassy finish uninterrupted by any stripes, waves, or even excess chrome trim. Slick and smooth are the new bywords in custom paint today.

The next good news is that the paint companies have got the new two-stage, two-part paint combinations sorted out. Lacquer is gone. Waterborne may be in the future in custom paint. But the paint systems, and especially the custom color possibilities, available from the major paint suppliers today are better than ever, last much longer, and go on without unwanted surprises like fisheyes, separation, bleeding, or bubbles.

Traditional pearl (right) is mixed in clear, so it has to be carefully and evenly painted over a solid-color, complementary base (left), which is sprayed over primer coats. The pearl must be cleared on top, both to give it gloss and allow it to be rubbed out, making it a three-stage paint.

Traditional pearl (right) is mixed in clear, so it has to be carefully and evenly painted over a solid-color, complementary base (left), which is sprayed over primer coats. The pearl must be cleared on top, both to give it gloss and allow it to be rubbed out, making it a three-stage paint.

Better yet, these same paint companies have developed what were once considered custom-only colors that are so easy to apply, weather resistant, and durable that they are being used on new cars right on the assembly line. Many of these new factory colors, ranging from pearl whites to candy-looking reds combine both fine metallic and pearl particles in the same basecoat, so they can be applied in a two-stage (basecoat/clearcoat) process. These factory colors can be just as easily applied to your perfectly prepared rod or custom with even more stunning results-and much less work than the old pearls and candies.

PearlsIn the past, pearl colors tended to be subdued pastels, though still rich. They also had to be painted in a three-step process, starting with a straight-color-tinted basecoat, followed by the pearl coat in a matching shade, topped with clear. Because the pearl coat was translucent, it had to be painted deftly in evenly overlapping passes to avoid streaks or blotches.

While many of today's pearls still require a three-stage process (even on some factory new cars), the good news is that a much brighter, wider variety of pearl colors is now available, and many now come in a single-stage basecoat, usually mixed with a percentage of metallic, that is much easier and less time-consuming to spray.

Today more pearl-tinted colors are being offered by OE manufacturers. You might not see many on the highway, but if you look through factory color-chip charts at your local automotive paint store or dealer showroom, you'll find all kinds of luscious pearl coat colors to choose from.

Straight ColorWhat truly defines a custom paint job is not whether it sparkles, glows, or dances with flames. No. It's any paint job that is better than factory-custom-applied, by hand. That means getting the surfaces straight and smooth, aligning body seams and gaps, priming and block-sanding by hand, prepping and painting surfaces such as doorjambs and under the hood, and color-sanding and rubbing out the final paint to a glasslike finish.

Every custom paint job should be done this way. But it's just as effective with a simple single-stage color such as red, blue, green, or especially rich black. Since it doesn't need a clearcoat, such a custom paint job is not only the easiest and least expensive to do, but it's also the easiest to touch up if it gets scratched or damaged.

Flex AgentsCustom paint doesn't always go on sheetmetal. The trend is the increased use of plastics and flexible parts. Nick Bartoszek, director of global product management at Sherwin-Williams Automotive Finishes, notes that "the cars we are customizing today are lighter because of the use of plastics. These parts are typically flexible and had required the use of a flex additive to meet the performance requirements. Some of the improvements that have been made to the resin technologies have limited the need for flex additive in the clearcoats. Sherwin-Williams Automotive Finishes launched Ure-Flex technology to incorporate flexibility into its premium clearcoat systems. This way, quality is never compromised."

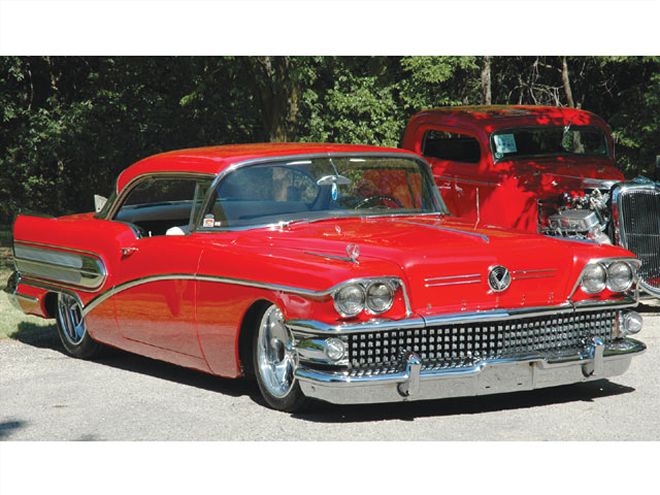

I used to call '58 Buicks ugly, but this one isn't. And all it really took to make this behemoth outstanding, besides the wheels/tires/lowering, was block-sanding the big body straight and shooting it with a simple coat of fire-engine-red paint. No stripes, no graphics, and a single-stage nonmetallic color like this doesn't even need a clearcoat. Black would work, too.

I used to call '58 Buicks ugly, but this one isn't. And all it really took to make this behemoth outstanding, besides the wheels/tires/lowering, was block-sanding the big body straight and shooting it with a simple coat of fire-engine-red paint. No stripes, no graphics, and a single-stage nonmetallic color like this doesn't even need a clearcoat. Black would work, too.

ClearcoatsNick says, "Major improvements in clearcoat technology include changes in the resin structure, resulting in improved quality, durability, gloss, and application. In the custom paint market, protecting the car owner's investment is key. Similar to the OEM car manufacturers, custom car owners are beginning to demand special finishes that protect their vehicles and keep them looking great, mile after mile, wash after wash. That's why Sherwin-Williams Automotive Finishes has worked to develop a clearcoat that offers built-in flexibility and superior scratch resistance."

So what is on the horizon? Nick notes that "Film Healing Technology (FHT) is a unique clearcoat that will actually heal minor abrasions and car wash swirls after exposure to sunlight. The process works as the sun heats up the car panel and warms the clearcoat resin and actually allows the finish to reflow and heal itself. Not only does it resist scratches, but it also has outstanding gloss. This allows the car owner to enjoy a beautiful finish for many years to come."

CandiesCandy apple paint-a rich, transparent Kool-Aid color sprayed over a bright, sparkly base, such as silver or gold-has always been one of the most striking and beautiful of custom paint jobs. The good news is that brilliant candies are now available in modern, catalyzed paints that match the best colors lacquer has to offer but will stand up to the elements much better.

Or how about suede and shine? Ray Dunham's '36 taildragger from the feature in the May '07 issue titled "The One" is the perfect blend of the two finishes.

Or how about suede and shine? Ray Dunham's '36 taildragger from the feature in the May '07 issue titled "The One" is the perfect blend of the two finishes.

To get the true depth and glow of traditional candies, many must still be very carefully and evenly sprayed over some sort of metallic silver or gold base. However, all of today's major paint companies offer a wide range of custom colors, including candies and pearls, in many more hues than were available in the old days, when most custom painters mixed their own colors (that could never be duplicated or touched up). Further, in the case of candies, many more base colors are available, and the companies' custom charts clearly show the range of colors that can be obtained by spraying one candy color over various bases or different candy hues over the same base. You can check these out in special custom color-chip catalogs at your paint store or on painted panels at the companies' displays at major events.

So what is leading the charge with the vibrant metallics and metalflakes available to enthusiasts today? David Kidd of Planet Color (a division of Sherwin-Williams Automotive Finishes) says, "Metallic color enhancements, like mica and pearl, have been around for a lot of years. What we have added at Planet Color is crushed glass and crushed mirrors. These enhance the effect that metallics and pearls have by creating reflectivity and producing more sparkle and brilliance. They also create space in the coating that helps to align the metallics and pearls to reduce mottling."

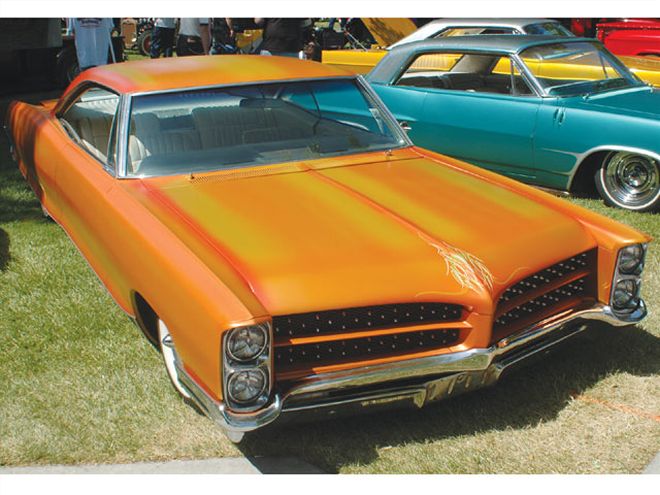

You can do anything you want with custom basecoats. This big Pontiac provided ample surface for spraying fogs and blends of tangerine pearl over a gold base. The owner could coat this with clear at any time and rub it out, but the pinstripes on the nose tell us it's going to stay the way it is . . . for now.

You can do anything you want with custom basecoats. This big Pontiac provided ample surface for spraying fogs and blends of tangerine pearl over a gold base. The owner could coat this with clear at any time and rub it out, but the pinstripes on the nose tell us it's going to stay the way it is . . . for now.

Suede ShadesPerhaps the biggest news in today's custom paint trends is what we're calling suede. It started out as simple primer on unfinished rods, or the now-prized patina (faded paint and/or rust) of aged sheetmetal. The problem was that some wanted rust and some didn't, and some saw such cars as works in progress, while others considered them done. The problem is that real primers, as used on cars under construction, are porous and allow moisture to penetrate, thus leading to underlying rust on metal surfaces-not good if you want to preserve the metal or ever finish the car. So waterproof alternatives were tried, such as PPG's DP series of primer/sealers in various shades, a semiflat (semigloss?) finish paint called Trim Black, or even clearcoats with flattening agents added, sprayed over primer.

This subject grows large and complex in a hurry, so we can't get too deep into it here. But the next element is color. Since the basecoat of any two-stage (basecoat/clearcoat) modern paint sprays on easily and dries to a satin sheen-presto!-leave off the clearcoat and you have a suede finish, in any color you want (including pearls or even candy). Since most of these basecoats are catalyzed, they resist water absorption. And if you want to have fun, you can spray fades, blends, flames, or scallops in additional layers of basecoats or even pinstripe on top of it.

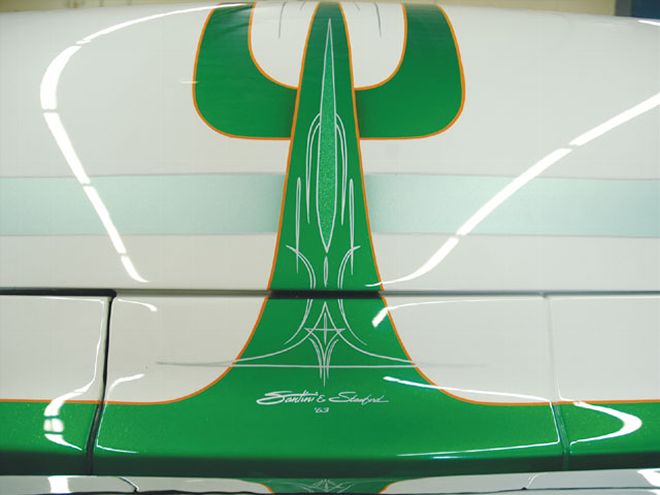

On this '50s- style mild custom Impala, we see some candy-colored scallops as well as a bit of metalflake. More important, striper Steve Stanford loaded his dagger brushes with various colors of catalyzed 1-Shot to both outline the scallops and add his own pinstripe designs before painter Santini buried it all in urethane clear, allowing him to color-sand and rub out the whole car to a glass-smooth finish that will protect everything underneath it.

On this '50s- style mild custom Impala, we see some candy-colored scallops as well as a bit of metalflake. More important, striper Steve Stanford loaded his dagger brushes with various colors of catalyzed 1-Shot to both outline the scallops and add his own pinstripe designs before painter Santini buried it all in urethane clear, allowing him to color-sand and rub out the whole car to a glass-smooth finish that will protect everything underneath it.

Now, you might think this takes us 180 degrees from our initial premise of true custom paint being better than factory original. In one way, you're absolutely right. If you don't want to do the assiduous panel straightening, block-sanding, and rub-out of a primo paint job, a suede finish will hide the problems that glossy paint would magnify. Also, adding creative color to the suede finish can make the car look that much better, without the extra work.

On the other hand, if the vehicle really is under construction, why not drive and enjoy it while it's still in some shade of suede? Continue to work and block-sand the body as you go, adding more primer as needed. Spraying basecoats on it will give you a good idea of how certain colors will look. When it's finally straight enough and the color is right, spray a glosscoat on it, rub it out, and you're done. Or maybe satin and smooth are really your preferences over slick. That's the true fun of hot rodding. You can do whatever you want.

PinstripesHand-painted pinstriping with special dagger or quill brushes is an art much older than automobiles, but it will continue to be an inherent element of rod and custom painting for generations to come. While all sorts of fads and styles come and go, the method of pulling fine lines remains the same. In the old days, however, when custom paint jobs were done in lacquers, and stripes were applied in slow-drying 1-Shot enamel, the stripes had to be painted on top of the rubbed-out lacquer, making them very vulnerable to scratching or even rubbing off with aggressive waxing.

Unfortunately, modern urethane clears have the same effect on pinstripes as clear lacquer, causing them to wrinkle if sprayed on top. The good news is that a couple of paint companies, such as House of Kolor, have come out with lines of urethane striping enamels with catalysts, and venerable 1-Shot has recently introduced its own hardener that can be added to its striping enamel. This way the striper can lay down his lines using the slow-drying (though catalyzed) enamel, and then the painter can cover it with catalyzed clearcoats and rub the whole surface out, thus fully protecting the pinstripes while also giving a perfectly smooth finish to the vehicle.

The FutureCurrently, the challenge facing the automotive finish industry is reducing Volatile Organic Compounds (VOC) found in paint systems. Much of the low-VOC development work is a result of legislation from California, Canada, and Europe to improve air quality. According to Nick Bartoszek, "Many people believe the new rules going into effect are waterborne rules. That's not the case. Waterborne basecoat technology is only being used to reduce VOC because lowering the VOC on a solvent-borne paint system and keeping the performance level has been challenging, but not impossible. In fact, we are using the waterborne system as the color coat and using low-VOC solvent-borne primers and clearcoats. An example of a waterborne basecoat product is Sherwin-Williams' Premium AWX system."

Though usually best reserved highlighting details on the car, it's also possible to make the pinstriping a focal point on the car. Here the artist has chosen a tribal style flame pattern laid down in a lighter shade of green that compliments the body color nicely.

Though usually best reserved highlighting details on the car, it's also possible to make the pinstriping a focal point on the car. Here the artist has chosen a tribal style flame pattern laid down in a lighter shade of green that compliments the body color nicely.

Just like solvent-borne products, waterborne products have their own set of rules of application. If you follow the rules, life is pretty good and quality is second to none. Shortcut the rules and quality will suffer. Waterborne products require spray equipment with stainless steel fluid passages, clean air (free of oil and water), and the biggest challenge-heat and air movement to cure the waterborne materials.

"Since the primary solvent in waterborne is water, it works a little differently than a solvent-borne coating. Instead of evaporating the solvent out of the coating, the painter needs to dehydrate the water from the coating with heat and air movement," Nick says.

Among the benefits of waterborne materials is that waterborne technology allows the manufacturer to load more pigment in the color coats, so the paints cover about 25-33 percent better than the previous technology.

Knowing that waterborne is not going to be applicable for everyone, Sherwin-Williams Automotive Finishes has also built a VOC-compliant solvent-borne system that meets the California and Canadian VOC rule. According to Nick, "S-W's Dimension Pro Basecoat system is a simple, easy-to-use-and-mix solvent-borne system that performs similarly to non-VOC-compliant solvent products but meets all legislation VOC requirements. This system offers good coverage, a sandable basecoat, and dries very quickly.

Lastly, VOC regulations have also affected primers and clearcoats, but these products have lower VOCs (2.1 pounds/gallon VOC) but still offer great performance, gloss, and speed of dry. According to Nick, "Many changes have taken place, but overall the quality of the products keeps improving."