All major manufacturers have at least one transmission that serves as the backbone for their automatic shifting needs in the world of performance/street and racing, and for the majority of Chrysler products it's the venerable A727. Beginning in 1962 when it replaced the heavy cast-iron–cased A488, the 60-pound lighter aluminum-cased 727 came with numerous improvements, including an inch-larger 11.75-inch torque converter and beefed-up internals. Known as the TorqueFlite, when it comes to varied service use and abuse, it's hard to beat this guy. The new workhorse trans had to be able to handle just about anything the Pentastar people needed. Think about it: TorqueFlites (in 727 and lighter 904 form) have been installed behind everything from Slant Sixes to Super Stock Hemis. These things have hauled groceries, heavy loads, and ass down the dragstrip. They've been neutral dropped, Mannix turned, and subject to all manner of hard use in Chryco muscle cars.

And they were good at it too; Chrysler installed them in various cars and trucks up until the 1980s. When the need for an overdrive-enabled trans arose, the A727 morphed into the A518 (46RH/46RE), and then the A618 (47RH/47RE). They had fancier names, another gear, and modern electronics, but they're all basically A727 architecture. Those transmissions were installed in various rear-wheel-drive platforms up until 2007. The 48RE that was used behind Cummins diesels and V-10s in 2500- and 3500-series trucks is also of 727 ancestry. Though it faded from use for a while, the TorqueFlite name is so associated with strength that Chrysler even revived it recently.

When we decided to work with Indy Cylinder Head to build the 657hp aluminum monster for our 1968 Valiant project, we knew it would be the deciding factor for the rest of the driveline. Everything had to be up to the task repeatedly and reliably. For the trans, the A727 was the logical choice, and TCI's StreetFighter version fit our needs perfectly. Built to withstand the toughest street machines, the StreetFighter has upgraded clutches and bands, new sprags/roller clutches to increase holding capacity, an improved lubrication system that increases fluid flow to planetaries and internals, and higher line pressure for extra firm shifts and greater torque capacity with less slippage. We're planning to put all of that stuff to the test. Check out how this critical link for our Valiant came together at TCI's headquarters.

We show you how TCI built an A727 TorqueFlite StreetFighter to handle the 657hp punch from our Indy low-deck big-block.

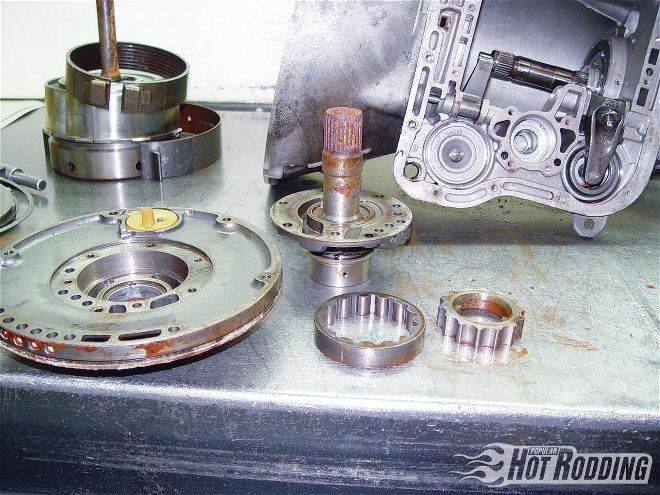

1. TCI always has vintage cores around ready for building, and the guts of our 727 donor looked fairly good for their age. The reverse drum is pretty hazy and the sun shell has a dusting of rust, but both will either be polished back to perfect or replaced; TCI does not turn down drums on a lathe.

1. TCI always has vintage cores around ready for building, and the guts of our 727 donor looked fairly good for their age. The reverse drum is pretty hazy and the sun shell has a dusting of rust, but both will either be polished back to perfect or replaced; TCI does not turn down drums on a lathe.

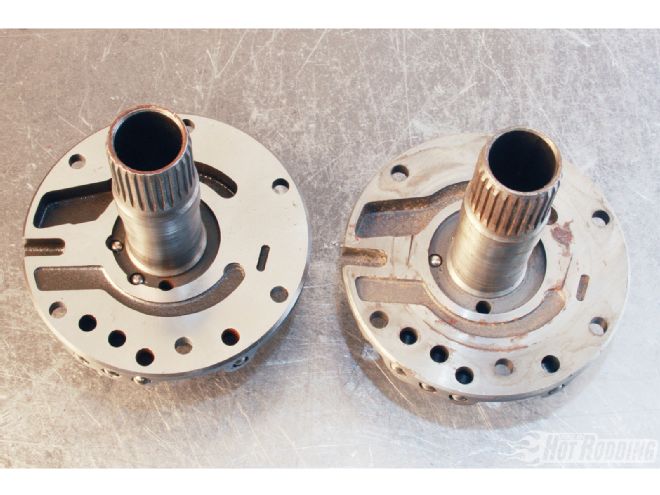

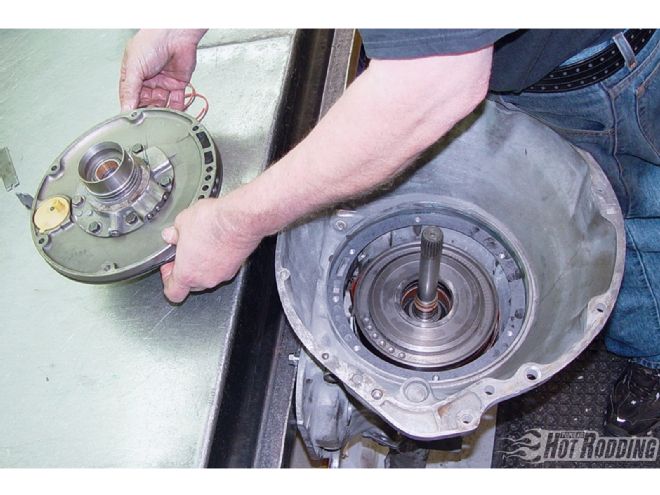

2. The pump will be resurfaced and the inner and outer pump gears will be replaced with new parts. If need be, the pocket in the pump where they ride will get resurfaced. In some cases, oversized gears will be swapped in, but ours were within spec with stock size gears.

2. The pump will be resurfaced and the inner and outer pump gears will be replaced with new parts. If need be, the pocket in the pump where they ride will get resurfaced. In some cases, oversized gears will be swapped in, but ours were within spec with stock size gears.

3. After cleanup, the stator support and shaft was deemed too rusty to reclaim, so it was swapped out with a new part. TCI is very particular about parts meeting their spec, so questionable old parts will never be reused.

3. After cleanup, the stator support and shaft was deemed too rusty to reclaim, so it was swapped out with a new part. TCI is very particular about parts meeting their spec, so questionable old parts will never be reused.

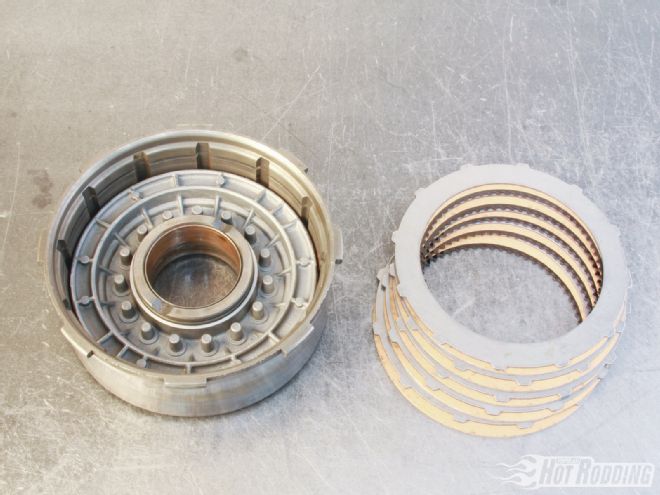

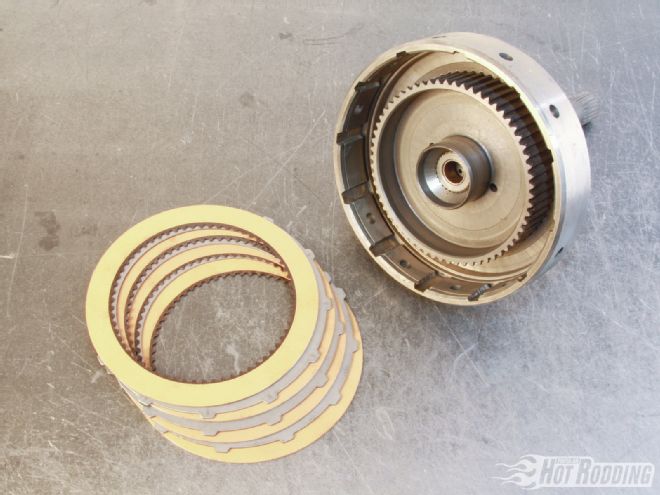

4. One key to the higher power handling of the TCI StreetFighter is the machining that allows five clutches to be installed for high gear versus the stock four clutches.

4. One key to the higher power handling of the TCI StreetFighter is the machining that allows five clutches to be installed for high gear versus the stock four clutches.

5. The forward drum also gets treated to upgraded clutches from BorgWarner. The increased holding power means more power gets reliably sent to the wheels.

5. The forward drum also gets treated to upgraded clutches from BorgWarner. The increased holding power means more power gets reliably sent to the wheels.

6. Once all the drums are cleaned and inspected, the reassembly can begin. The BorgWarner clutches are installed into the forward and high-gear drums.

6. Once all the drums are cleaned and inspected, the reassembly can begin. The BorgWarner clutches are installed into the forward and high-gear drums.

7. Showing the piece-by-piece reassembly of the StreetFighter takes more space than we have, but simplified, the rear drum friction band goes in first, mating up to the rear band articulating arm. The reverse clutch drum and ring gear and planetary slide in next. It’s followed by the rear planetary gearset, the sun shell and sun gear, the front planetary, and the front and rear clutches. The 727 uses a for-the-time revolutionary Simpson gearset designed by Howard Simpson that uses one sun shell for two planetary gears.

7. Showing the piece-by-piece reassembly of the StreetFighter takes more space than we have, but simplified, the rear drum friction band goes in first, mating up to the rear band articulating arm. The reverse clutch drum and ring gear and planetary slide in next. It’s followed by the rear planetary gearset, the sun shell and sun gear, the front planetary, and the front and rear clutches. The 727 uses a for-the-time revolutionary Simpson gearset designed by Howard Simpson that uses one sun shell for two planetary gears.

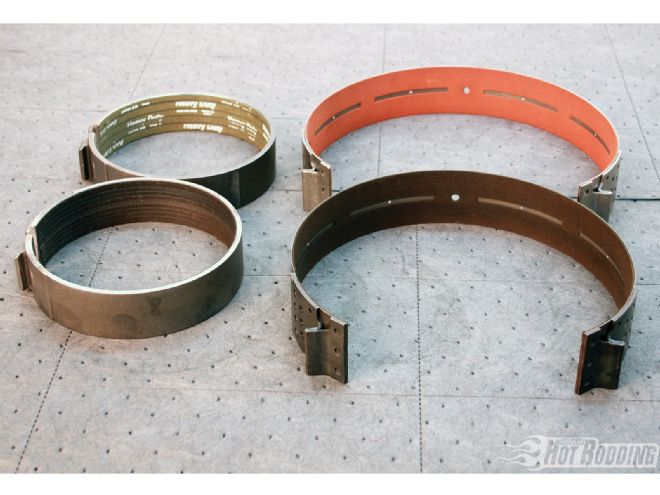

8. TCI also upgrades the bands to much more aggressive material as well. On the left is the stock versus upgraded reverse bands. The new one is a Kevlar material, which will be far more durable and long lasting. On the right is the stock versus upgraded Second gear band, or intermediate band. These aren’t Kevlar, but they are a high-friction BorgWarner material designed to apply more grip to the drum.

8. TCI also upgrades the bands to much more aggressive material as well. On the left is the stock versus upgraded reverse bands. The new one is a Kevlar material, which will be far more durable and long lasting. On the right is the stock versus upgraded Second gear band, or intermediate band. These aren’t Kevlar, but they are a high-friction BorgWarner material designed to apply more grip to the drum.

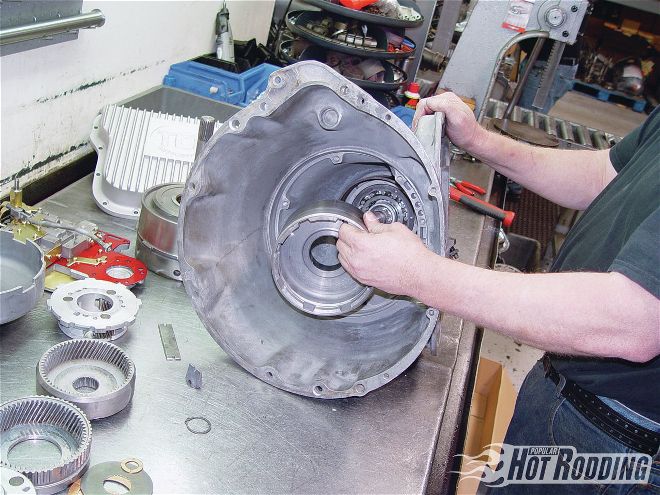

9. Once the rotating parts are reassembled, the rebuilt front pump is bolted back into place.

9. Once the rotating parts are reassembled, the rebuilt front pump is bolted back into place.

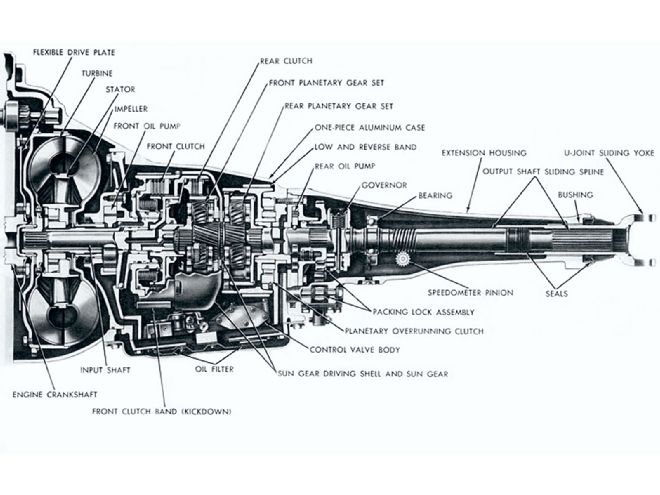

10. Have trouble picturing how all these parts fit together? No worries, for better illustration this cutaway from a 727 service manual shows exactly how the new TCI components are arranged.

10. Have trouble picturing how all these parts fit together? No worries, for better illustration this cutaway from a 727 service manual shows exactly how the new TCI components are arranged.

11. Both the front and rear band are tightened down to 72 ft-lb and then backed off approximately two turns to get the right amount of tension.

11. Both the front and rear band are tightened down to 72 ft-lb and then backed off approximately two turns to get the right amount of tension.

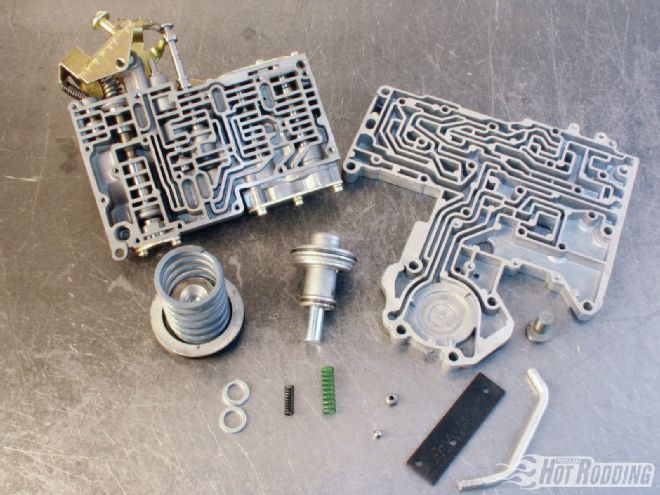

12. Just as important as the hard parts is how the trans handles its fluid. This is the upgrade kit TCI uses in the StreetFighter, which consists of a reverse servo upgraded with a stronger spring, a modified accumulator to firm up Second gear, higher-rate springs, and an oil restrictor for the high gear clutches. All of these little changes add up to faster reacting, firmer shifts.

12. Just as important as the hard parts is how the trans handles its fluid. This is the upgrade kit TCI uses in the StreetFighter, which consists of a reverse servo upgraded with a stronger spring, a modified accumulator to firm up Second gear, higher-rate springs, and an oil restrictor for the high gear clutches. All of these little changes add up to faster reacting, firmer shifts.

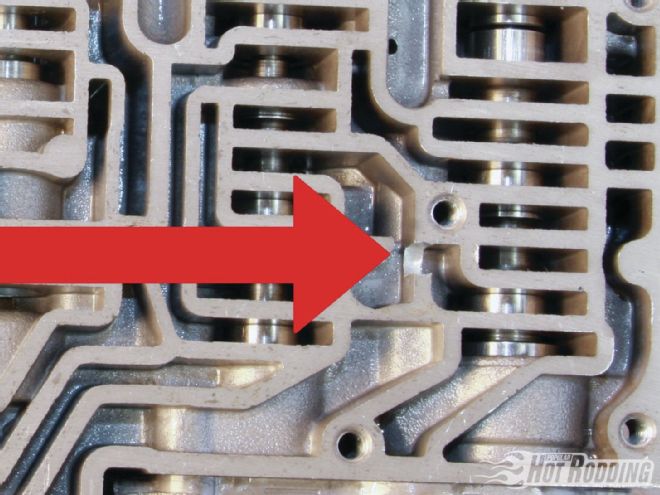

13. The circuitry in the valvebody gets a little alteration as well; note the channel that is opened up to increase oil flow for faster, firmer upshifts.

13. The circuitry in the valvebody gets a little alteration as well; note the channel that is opened up to increase oil flow for faster, firmer upshifts.

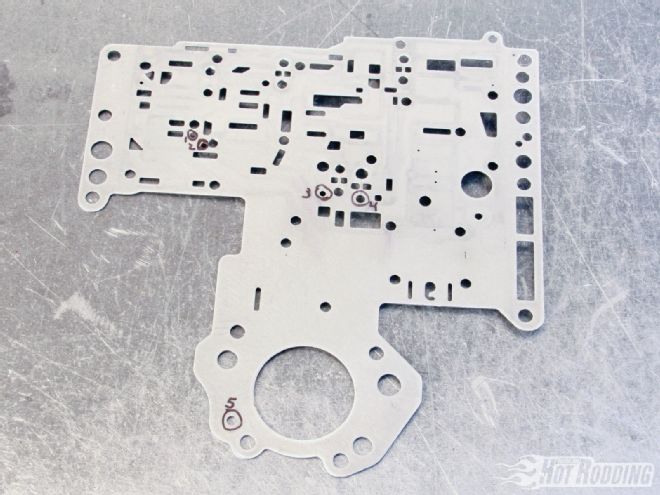

14. The separator plate gets a few key holes drilled out as well. The five circled holes are opened up from ⅛- to 3/16-inch to allow more fluid flow.

14. The separator plate gets a few key holes drilled out as well. The five circled holes are opened up from ⅛- to 3/16-inch to allow more fluid flow.

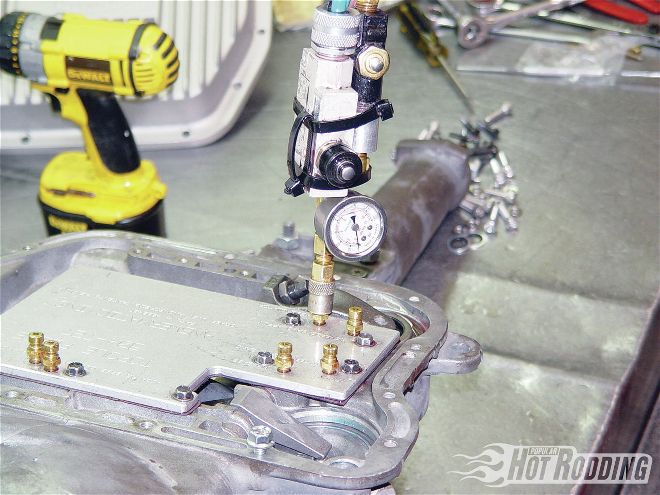

15. Some shops use air to perform their pressure checks, but your trans doesn’t run on air so TCI performs their leakdown test with actual trans fluid. Each of the posts checked get 100 psi of pressure and each circuit has its own tolerance to be met before the trans gets a passing grade.

15. Some shops use air to perform their pressure checks, but your trans doesn’t run on air so TCI performs their leakdown test with actual trans fluid. Each of the posts checked get 100 psi of pressure and each circuit has its own tolerance to be met before the trans gets a passing grade.

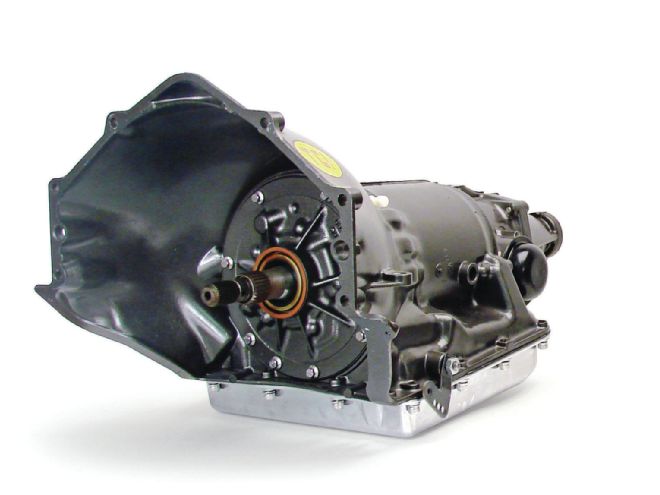

16. Once it has been fully tested, our StreetFighter gets one of TCI’s cast-aluminum pans with cooling fins for better sealing and to help reduce oil temp. Now we’ll be able to get our Indy engine’s power transferred rearward without fear.

16. Once it has been fully tested, our StreetFighter gets one of TCI’s cast-aluminum pans with cooling fins for better sealing and to help reduce oil temp. Now we’ll be able to get our Indy engine’s power transferred rearward without fear.