I have to admit that the thought of pulling the proven 307ci V-8 / T5 transmission combo in my C10 is something that gives me great hesitation. It’s provided me with thousands of trouble-free miles as a daily driver as well as churning out a few thousand highway miles to Bonneville and back.

But there’s one thing that combo lacks—power. It grunts just as good as you’d expect a 40-plus-year-old engine to grunt, but it just doesn’t give that instant seat-of-the-pants pull that a modern drivetrain combo can provide and I have to drive it with a bit of subtlety and nuance due to the fact that the transmission just can’t handle a lot of torque given the 4,000 pounds it has to motivate every time you mash the go pedal.

That said, in the next iteration of the C10 build, it should come as no surprise that I plan to put a little more power under the hood with the components to back it. This month, we’re going to cover the initial installation of the most important component between what makes the “go” and what puts it to the road, the transmission.

This piece of revolving steel in aluminum is responsible for not only keeping the engine in its “sweet spot,” it’s also responsible for maintaining a decent highway speed while not spinning either the rear tires or the engine to death while doing so.

In the past, it was a matter of give and take when it came to getting off the line and cruising down the highway; usually one thing gave something up to suit the other. A TH350 is a good example of this. You could build a turbo trans to launch hard off the line, but at 80 mph, it was winding wind in a serious manner. A taller rear gear or tire to counteract the high cruising rpms shaved effect off that awesome launch ability. It was a constant struggle of paying Peter versus paying Paul.

With the advent of the five-speed manual transmission, we found ourselves closer to that perfect storm of great off-the-line gearing coupled with an overdriven final ratio, but the grenade-like habits of those early trannies still had us giving something up for that ability.

Enter the Tremec T-56 Magnum. Based on Tremec’s production TR-6060 transmission that graced ZR Corvettes with its presence, we’re finally able to have our cake and eat it too.

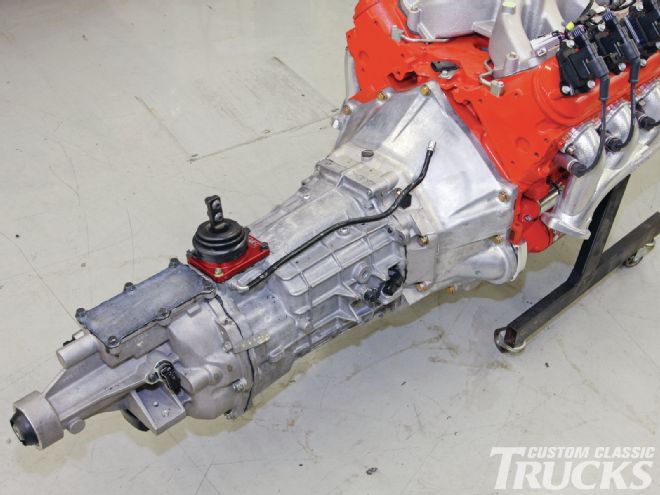

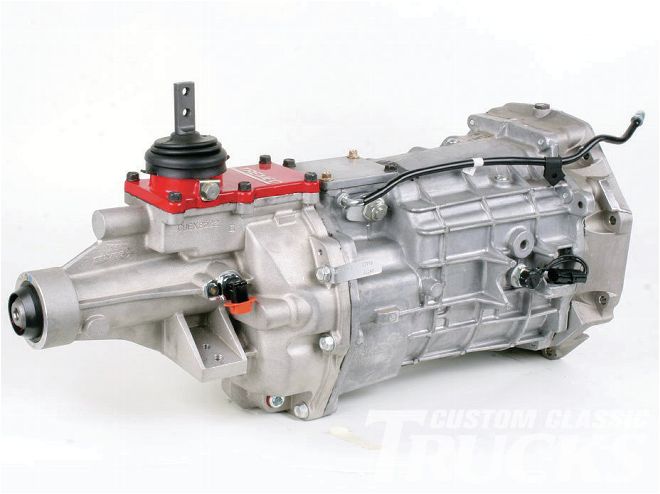

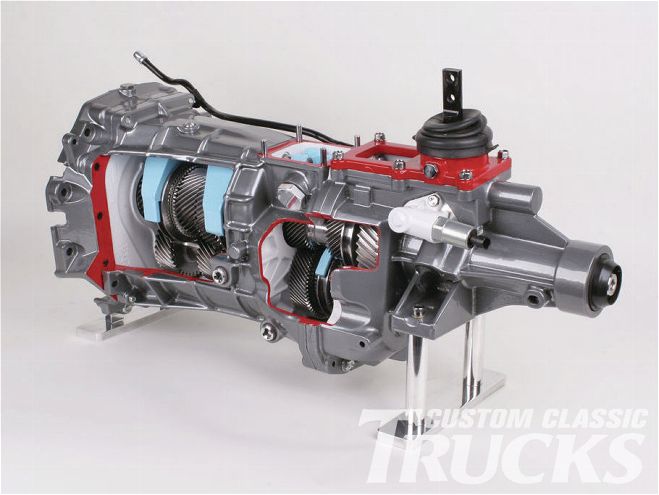

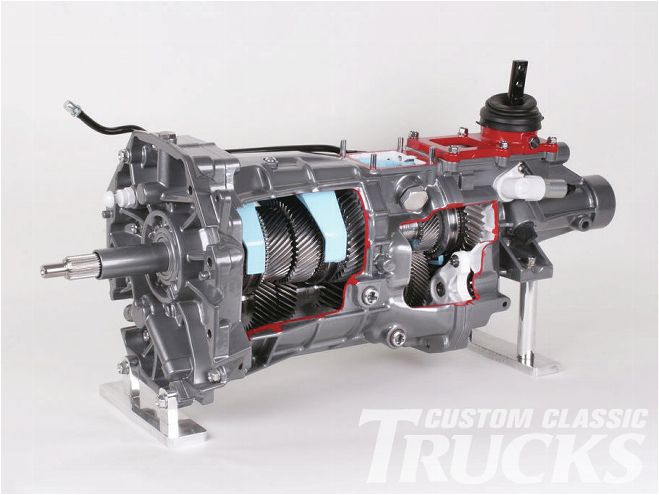

1-2. The granddaddy of all modern manual transmissions for classic trucks is the Tremec T-56 Magnum. The kingpin of Tremec’s high-performance lineup, the redesigned double-overdrive six-speed combines the best of Tremec’s current OEM technology with the proven performance of the TKO five-speed. This is the aftermarket version of the TR-6060 transmission found in the ZR1 Corvette and ACR Viper, capable of withstanding 700 lb-ft of torque, while providing unbelievably crisp shifts.

3-4. Triple-cone synchronizers on the first four gears and double synchros on fifth, sixth, and reverse provide butter-smooth shifting, while the 26-spline input and 31-spline output shafts enhance the overall strength of the trans. The T-56 Magnum can be ordered in a myriad of gear combinations; we chose the 2.97 first and 0.63 sixth gear combo for a nice spread. The option of either a mechanical or electronic speedo drive as well as a number of possible shifter locations make the T-56 Magnum one of the most versatile transmissions ever to hit the market.

5. Hurst Driveline Conversions provided the kit to mate up the T-56 Magnum to our Chevrolet Performance Parts crate LS327 engine, including this brand-new cast-aluminum bellhousing.

6. A simple, bolt-in hydraulic throwout bearing is a nice change of pace from the adjustable units I’ve installed in the past, as this unit rids the installer of second guessing any measurements and shim installation. A Tilton master cylinder won’t take up precious firewall real estate and should mount nice and tight aside the brake booster.

7. The neat thing about the provided Tilton master is that it provides a number of reservoir options. Using either the large or small reservoir, they can either be directly mounted to the master cylinder or remotely mounted elsewhere on the firewall, making the install very flexible.

8. For most classic truck applications, a mechanical speedo is going to be put into use so Hurst ships a new cable as standard. It is possible, however, to hook up an electronic speedo via the provided VSS speedo pigtail, which attaches to the plug on the rear passenger side. Also included is a new six-speed shift knob, needle roller pilot bearing, and a pigtail for the backup light plug on the front passenger side.

9-10. Every bolt and washer needed to mate up the trans, bellhousing, engine, and crossmember is included as well as those required for the pressure plate, flywheel, and crank. A new slip yoke is also included to ease driveshaft fabrication as well as a new trans mount.

11. A new LUK heavy-duty 11½-inch clutch and pressure plate is provided in the kit and is capable of handling 500 horsepower.

12. Of course the best clutch in the world is no good if the flywheel it’s mating to is smoked, which is why Hurst Driveline Conversions provides a brand-new flywheel to complement the rotating assembly.

13-14. Naturally, the flywheel is the first thing to install on our LS engine. Six fasteners equipped with factory thread locker will ensure the flywheel won’t separate from the crank flange.

15. Once the flywheel is finger tightened evenly against the crank flange, each fastener is tightened to 74 lb-ft. I like to start with one fastener and move around the bolt circle in a clockwise direction tightening each fastener to 35 lb-ft first, then making a second pass to the full torque spec. This ensures the flywheel is tightened evenly against the crank flange. Note the use of a flywheel holding tool to keep the engine from spinning.

16. Next, it’s time to insert the roller pilot bearing followed by the clutch. A plastic clutch guide tool will ensure the clutch remains aligned once the pressure plate is tightened. Be sure the pilot bearing is greased, but don’t go overboard with it, otherwise the input shaft of the trans may hydraulic, making it hard to seat it at first.

17. Here’s the clutch plate and alignment tool in place.

18. The pressure plate is then installed using the dowel pins for alignment.

19. I like to put Loctite on these fasteners as well. It’s no fun when your pressure plate comes loose…

20. The pressure plate fasteners are then torqued using the same method as the flywheel, this time to a torque yield of only 30 lb-ft.

21. Due to the close tolerances between the hydraulic throwout bearing lines and the bellhousing, it’s recommended to install the bellhousing to the transmission first, opposite to conventional transmission installations. In this case, I use anti-seize as the steel fasteners are threading into the aluminum bellhousing.

22. Next, two fasteners secure the throwout bearing to the flange of the transmission. No shims, no measuring required. Pretty cool.

23. With the bellhousing and throwout bearing installed on the transmission and the clutch assembly to the engine, it’s time to mate the two. Doing this outside the confines of a tight engine compartment is nice in that you can double check everything and top off all the fluids before installing the drivetrain in relative comfort.

24. Here’s the finished assembly, though there are a few more things to address before we’re ready to move on.

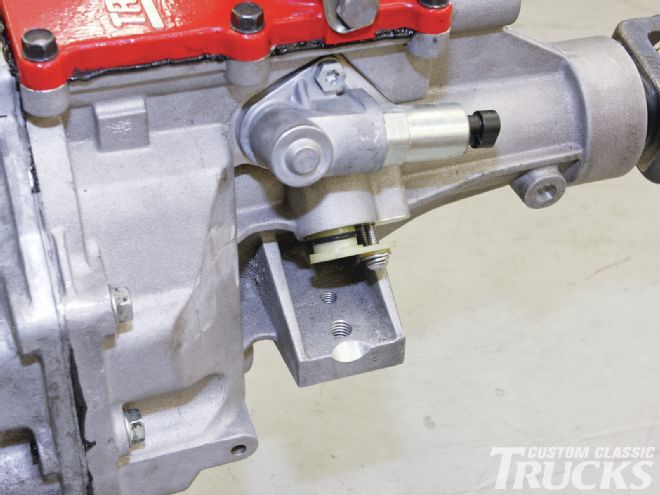

25. First off, since we’re not going to be using a mechanical speedometer (we’ll be using a GPS system), the speedo drive boss needs to be capped off. Ford part number F2UZ-7H183-A is the one you need; don’t ask why it’s a Ford number though! The reverse lockout solenoid provides a load-limiting gate restriction and needs to be connected to a 12V momentary switch. This prevents accidental shifts into reverse without first hitting the switch.

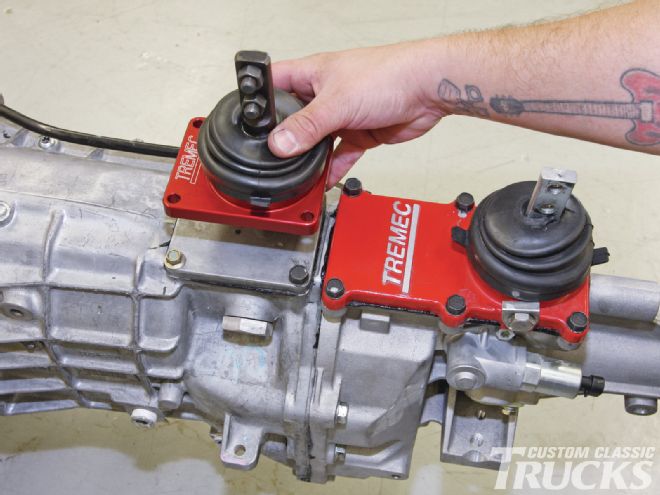

26. Next, we need to relocate the shifter to the midpoint location to get it to clear our stock bench seat in the C10.

27. Installing the shifter is about as easy as it gets. Simply remove the cover plate and drop the shifter into place using the same hardware. A little black RTV silicone ensures it won’t leak.

28. The new shifter position is about 19 inches from the rear of the engine block. Pretty close to where the shifter sits now on the T5, about 18 inches from the rear of the small-block Chevy. Hopefully, the new shifter will pop right through the current hole in the floor without any further modifications. You can see that the midpoint location moves the shifter approximately 7 inches forward of the rear mounting point.

29. The midpoint shift kit also comes with a blocking-off plate for the rear shifter. You didn’t think we would keep two shifters in place did you?

30. Of the two connectors on the passenger side, only the connector near the engine will need to be hooked up in our application as that’s the backup light connection. The rear connector is for the VSS electronic speedo hookup.