When you hit the throttle on your Mopar's engine, the carburetor(s) dumps fuel into the engine, and the spark plugs ignite this fuel, in-turn, spinning the flywheel. The flywheel then transfers energy through the transmission, which then transfers that inertia through the driveshaft to the differential, spinning the tires and putting the power to the ground—or putting your tires up in smoke. Theoretically, the driveshaft is simply a link between the transmission and the car's rear end. While this is basically true, a driveshaft does a lot more than simply act as a connector.

To many people, a driveshaft is just a piece of tubing with a yoke at each end that is designed to accept a U-joint. For the best performance and highest level of shaft strength, the shaft itself needs to be as straight as possible, with the yokes properly aligned. This alignment of the yokes means a driveshaft is considered in phase. When the shaft is out of phase, one of the yokes is twisted in relation to the other. To make a good driveshaft, you need to build a shaft that is straight, has the yokes in proper phase, and uses appropriate material. But what material is appropriate for your Mopar? We thought you guys might want to get a little lesson in driveshafts, so we took a trip to Dynotech Engineering in Troy, Michigan, to get the low-down on spinning tubes.

A driveshaft is a driveshaft, right? Maybe back in 1970 that was the case, but now you have a choice of several different types of shaft material, depending on your application. Combine these different types of material with the endless combinations of slip yokes, u-joints, and pinion yokes, and there are literally hundreds of combinations for a custom driveshaft. When talking about driveshafts, there are a few terms that you should know about.

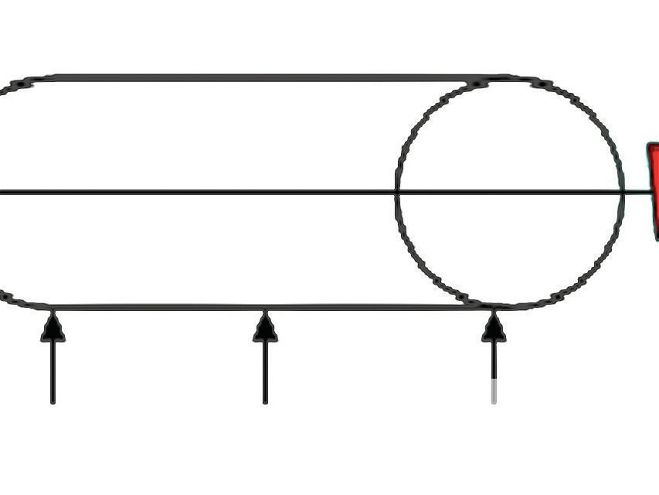

Tube Runout

This is a measurement of how straight your driveshaft is as it rotates about its diametric centerline (axis of rotation). Tube run-out is a direct contributor to driveshaft balance. If you have too high run-out (bent tube), your driveshaft will not balance without welding excessive weight on one side. Dynotech recommends tube run-outs at 0.020 inch or less over the entire length of the tube. During both the weld and balance phase of the driveshaft development, run-out should be checked and minimized (Drawing A).

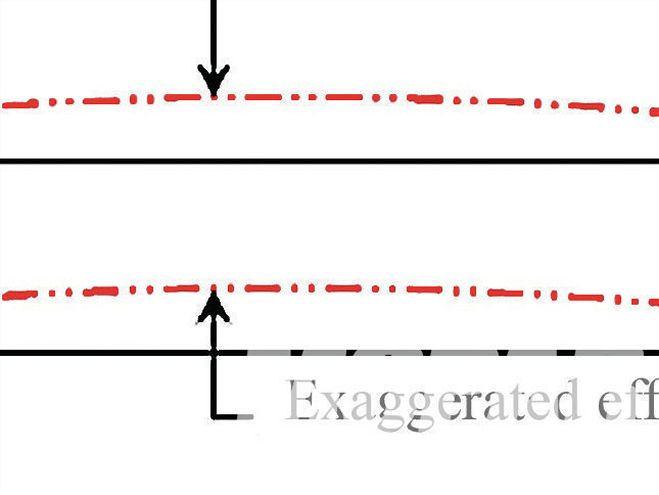

U-Joint Phasing and Clearance

This can play another significant role in the build and balance of your driveshaft. During the assembly of your driveshaft, you must make sure that the U-joint is centered in the weld and slip yoke. If the U-joint is off center, the entire weight of the driveshaft is rotating out of the driveshaft's centerline. In addition, if you do not have your U-joint phasing correct, you will create a severe vibration as a result of the non-constant velocity of the standard U-Joint. U-joint phasing is the alignment of the weld yokes during the build process. The centerline of the U-joint hole on the weld yoke at one end will be in line with the centerline of the U-joint hole on the other end. Dynotech uses specialty fixtures to ensure that the driveshaft is built with less than 0.0025 inch joint clearance after the U-joint installation and weld yokes are phased to within 0.1 degrees from one end to the other.

Balance

This is the final ingredient in making a good driveshaft. Dynotech balances all of their driveshafts to 0.20 oz-inches or less, and they tell us that they expect their measurement to repeat within 0.05 oz-inches. An ounce-inch is the standard balance measurement unit that relates to imbalance. Balance speed is another key element of driveshaft manufacturing. Your driveshaft should be balanced as close to operating speed as possible. Whatever imbalance is generated at 2,000 rpm is increased four times at 4,000 rpm, and nine times at 6,000 rpm. Even the smallest imbalance force at slow speed can make your car shake at high speed.

As you can see in the image, the universal receiver yokes that are getting welded to the driveshaft tube are aligned so that they are oriented in the same direction.

As you can see in the image, the universal receiver yokes that are getting welded to the driveshaft tube are aligned so that they are oriented in the same direction.

Anytime you increase the power output of a stock engine and subsequently increase the speed at which the engine operates, you need to look at driveshaft balance. Most factory driveshafts are balanced between 3,000 and 3,500 rpm. Spinning the driveshaft past that range can have a parasitic effect. Steve Raymond from DynoTech Engineering tells us, "We have had several NASCAR teams tell us that our driveshaft saves them 3 to 7 horsepower at the wheels of their race cars. That's why balance and design are important and why we manufacture shafts for about 85 to 90 percent of the NASCAR teams." Steve tells us that DynoTech suggests balancing a performance driveshaft at a minimum of 5,000 rpm and as high as 7,500 rpm. This ensures a properly tuned driveshaft that reduces vibration and efficiently transmits power to the wheels.

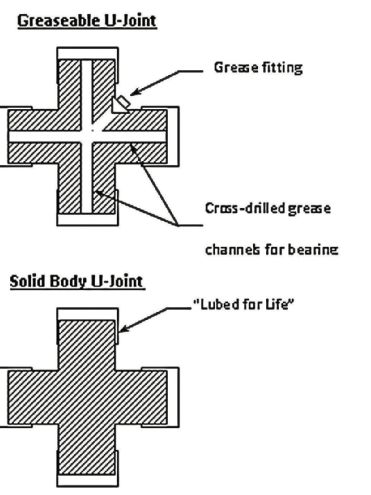

Solid vs. Greasable U-joint

Greasable or lubed style U-joints have several disadvantages. Because of their lube system, they are not as strong. The internal lube channel results in a smaller cross sectional area of material (less steel to resist the applied torque). They are naturally out of balance by using the zurk fitting on the body, and, with the added machining for the lubrication cross holes, you inherently induce a small amount of imbalance. They are warm forged, which is a less desirable process for strength. They require regular maintenance, but can last almost forever. Since they are lubed, they can leak grease at high speed. Solid-body U-joints have several advantages. Because of their solid design, they are inherently stronger because they make use of the greatest cross-sectional area possible. They are naturally balanced due to the symmetry of the part. They are cold forged, which is a more desirable manufacturing process for strength. They have a nylon sealing system and are lubed for life by the manufacturer. They might not last "forever," but the expected life is 100,000-plus miles (Drawing B).

Critical Speed

The critical speed of the driveshaft is the point where the first-order resonant frequency is excited by the speed of rotation. Avoiding long mathematical equations, it's the point that the driveshaft starts to jump rope, so to speak. There are several ways to handle the issue of critical speed, such as shaft material, size, and design. With something as simple as changing from a steel shaft to an aluminum shaft, you could see as much as a 12-percent increase in critical speed. Items such as balance, balance weight location, and joint clearance all have a direct effect on critical speed (Drawing C).

What Do You Really Need?

So what's the perfect driveshaft if you're looking at performance characteristics only? Here are our thoughts: You would like as lightweight and strong a shaft as possible. If you run your car on a chassis dynamometer, you will find that peak acceleration takes place at the same time as peak engine torque. This is because acceleration is defined as force divided by mass. In the case of your car, the mass is constant, so as force increases so must your acceleration. Therefore, the key is more torque! The torque that is most important is that at your drive wheels. The reason that engine torque and drive wheel torque differ is due to drivetrain loss. Drivetrain loss is the consumption of power needed to rotate the drivetrain, including friction and component mass. By reducing component mass (driveshaft weight), you consume less power. The less power you use to rotate your drivetrain, the more you have to propel your car down the strip or street. Lighter weight driveshafts give you the best options for reducing drivetrain loss. The second key factor in the ideal driveshaft is critical speed. You want to make sure your driveshaft operates well below its critical speed, or you will experience endless vibration problems and related excessive wear on mating components.

Deciding what is right for your car can be as simple as finding out what the different materials and yokes cost—or not. Think about this, if you have a heavy B-Body that races every weekend, with a thin wall driveshaft using small 7260 u-joints, you are asking for trouble. To the opposite, a Slant Six–powered Dart doesn't need a carbon fiber shaft with 1350 u-joints. In other words, do your research, and spend only what you need to, or at least what your combination should require. The following is a simple outline of what's available.

Steel Shafting

Chromoly is a steel tube that is usually drawn over a die or mandrel (D.O.M.). Chromoly steel has chromium and molybdenum added to the metal mix, and is considered the top of the line steel driveshaft. It's mostly used for heavy cars with high horsepower engines. Pros: This metal has a very high torsional strength.

Cons: This is also the most expensive of all steel driveshafts, and is only available in 3-inch diameter. It's also very heavy. This driveshaft uses steel weld-yokes.

D.O.M. 4140 is the most common aftermarket driveshaft used in racing situations. As long as the shaft is sized correctly, according to Dynotech Driveshafts, there's no car that can overpower this shaft.

Pros: This material is much stronger than seam tube and can withstand relatively high critical speed.

Cons: Not many. It's only slightly more expensive than a seam tube driveshaft. Like Chromoly, this is a fairly heavy shaft using steel weld yokes.

Seam Tube is the most common material used for OEM applications. It is perfectly suited for everyday driver or restored cars. Although stretching its limits is a possibility, it could be carefully used in circle track and drag racing applications.

Pros: This is the most cost effective driveshaft you will ever find.

Cons: It's also the weakest of all the steel driveshaft and has the lowest critical speed survivability rating, and is still heavy. Once again, steel weld yokes are used.

Aluminum Spinner

6061 T6 is the most common OEM application for an aluminum driveshaft. This type of shaft is best suited for everyday applications or restoration cars, sometimes a nice alternative to the heavy steel shaft, but is only suited for moderate horsepower.

Pros: Light weight, never rusts, and has a higher critical speed than steel shafts.

Cons: The weakest of all driveshafts. Remember, this is the same driveshaft used on applications such as the Astro van and Mustang. Also uses aluminum weld yokes.

Composite Tubing

Carbon Fiber is technology at its finest. This material is usually wound over a mandrel, while the fiber is soaked with resin. It is very well suited for circle track and drag racing. Pros: Very light weight and ultra strong.

Cons: By far the most expensive of all driveshafts. Can use either steel or aluminum weld yokes.

Hybrid Shafting

Aluminum wrapped with Carbon Fiber.

This is when you wrap any aluminum driveshaft with a thin carbon fiber over the outside diameter of the tube.

Pros: Light weight with extra strength and high critical speed. Price is less than a standard carbon fiber, as it is still an aluminum shaft; it's just wrapped with a thin layer of Carbon fiber.

Cons: Still not cheap. Uses aluminum weld yokes.

Summation

So now that you have the knowledge you need to decide what type of driveshaft you should get, all you have to do is get a little help from your friendly driveshaft shop, and you can pick the right material for your application and budget. mm