One of our goals for the Hot Rod Hauler was to get it a little closer to the ground and still maintain its load carrying capacity. We weren’t looking for an “in the grass” stance, but two or three inches would do it; we just had to find a way to deal with the twin I-beams up front.

In 1965, Ford introduced the twin I-beam front suspension in trucks. The advertising of the day that announced the revolutionary front suspension proclaimed these vehicles rode like a car and worked like a truck. Twin I-beam suspension offered improved wheel alignment and reduced tire wear the ads went on to say. Some of the illustrations that went along with a few of the early ads showed how when a wheel encountered a bump the other was unaffected. Interestingly, these drawings seemed to indicate that a wheel going over a bump moved straight up and down, however that must have been some ad agency’s version of the engineering involved because in the real world they behaved differently.

Ford’s twin I-beams were roughly 36 inches long and were attached to the frame on one side of the truck with a coil spring, shock, and the wheel at the other—forged steel radius arms located the axles front to rear. And while it was true that one front wheel could hit a bump and not impact the other, the suspension was tough and didn’t ride bad, but it didn’t take long for owners of Fords to find out that reduced tire wear was not one of the advantages. In fact, tire wear was an issue as was the tendency for the trucks to wander and follow seams in the roadway, particularly when the shocks were worn.

Twin I-beam front suspension made its debut in 1966 and remained fundamentally the same during production. They were simple, tough, and rode reasonably well.

Twin I-beam front suspension made its debut in 1966 and remained fundamentally the same during production. They were simple, tough, and rode reasonably well.

Over the years, we’ve had a love/hate relationship with the front end under our F-350. On the plus side, not much maintenance has been required. Other than regular lubrication, all that’s been done was a set of kingpins and a complete set of tie-rod ends at the 160K mark. On the other hand, it has had a tendency to knock the corners off a set of tires in short order, particularly when the shocks were shot, which happened with alarming regularity. Over the years, we’ve learned that the secrets to preventing premature tire wear were regular alignments and fresh dampers.

While the twin I-beam suspension is a mixed bag of good and not so hot for Ford aficionados, it really leaves a lot to be desired when altitude alterations are part of the plan. Raise or lower a truck with stock axles much past factory ride height, and the camber becomes such that you’ll be saying goodbye to the edges of your tire’s treads in no time. With Ford’s single solid axle predecessors, there have always been a number of options to get the front end down, such as modified stock or aftermarket dropped axles or getting rid of the stock front suspension entirely and replacing it with a custom-made independent or a clip. For many of the twin I-beam trucks, most of the same options exist (although we’re not aware of anyone dropping stock axles) as dropped replacement twin I-beams are available and there are a number of custom independents and clips that are suitable for F-150s. But in the case of an F-250, and certainly our ’73 F-350, load capacity becomes an issue with aftermarket IFS and passenger car clips, so, as far as we were concerned, the only option was to install dropped axles—and that decision led us to Airbagit.com.

Springing in stock form on our F-350 was via some stout coils. The original axles are forgings with a small amount of drop.

Springing in stock form on our F-350 was via some stout coils. The original axles are forgings with a small amount of drop.

Like many other aftermarket companies, Joe Morrow started his in a garage over 22 years ago. Ratical Tops was formed in 1987 and began manufacturing convertible tops for most every truck of the period, which they still sell today. In 1992, to better reflect their full line of products, the company was incorporated under the name AIM Industries, which they still go by today. In 1992 Chassis Tech was formed as the operation expanded and in 1994, AIM was the first company ever to put all four wheels on air with their Dodge Ram that was the feature truck on SEMA advertising in 1995. In 2002, the company was granted a patent for engineering the first AirStrut to replace a MacPherson strut. They also offer a variety of replacement dropped axles for just about any twin I-beam Ford from full-size trucks and vans to Rangers and two wheel drive Broncos. Airbagit’s dropped axles are a combination of fabricated I-beams with solid steel ends. Lengths vary depending on application as do the diameters of the kingpin and radius arm holes—our F-350 has 1-1/16-inch kingpins and 1-inch bolts securing the radius arms.

This is one of the stock Ford radius arms that positions one of the axles. The tops of the arms have to be modified for tie rod clearance.

This is one of the stock Ford radius arms that positions one of the axles. The tops of the arms have to be modified for tie rod clearance.

Installing the dropped axles is for the most part a remove and replace operation. However, there are some changes that are necessary. The tie-rod ends must be moved to clear the radius arms or the arms must be modified. In some kits, tie-rod end relocators are provided, in others, plates to modify the arms are included.

Here is the stock Ford shock mount. It’s held to the arm by rivets made from Kryptonite—they’re really tough and we finally resorted to a cutting torch to remove them.

Here is the stock Ford shock mount. It’s held to the arm by rivets made from Kryptonite—they’re really tough and we finally resorted to a cutting torch to remove them.

One Change Leads To Another

As we have said all along, our goal for the Hot Rod Hauler is to make it look cool but maintain its functionality. Now that we decided to install dropped axles we had another decision to make. Previously, we had removed a number of leafs from the rear springs to soften the ride and added air bags to maintain load capacity. So, while we installed the dropped axles, we decided to add air bags up front as well.

These pre-formed and drilled steel plates are used to modify the radius arms.

These pre-formed and drilled steel plates are used to modify the radius arms.

Airbagit.com offers universal air ride systems and parts as well as complete specific fit kits for everything from Alfa Romeos to Volkswagens, as well as foreign and domestic trucks. In most cases the kits are a 100-percent direct fit, but for some applications minor modifications are required. As our truck is a ’73 and a one-ton, we found that changes to the lower bag mounts were required, but in most cases it won’t be necessary.

With the dropped axles installed, the front bags at ride height, the nose of our F-350 is down about 3 inches from stock—just what we were after. The problem is, even after reducing the spring pack in the back, the rear of the truck is just too high. So we’re going to fix it, which means moving the spring mounts up on the frame and notching the ’rails for clearance. We’ll show all that next month along with everything you need to know about installing and plumbing the air management system. CCT

With the top portion of the arm cut away, the reinforcement plates can be put in place. The front holes align with those for the original shock brackets; those in the rear of the arm have to be drilled.

With the top portion of the arm cut away, the reinforcement plates can be put in place. The front holes align with those for the original shock brackets; those in the rear of the arm have to be drilled.

Shock Therapy

Shock absorbers fulfill a vital function, and if you’ve ever driven a truck with worn out shocks you know what it is—they dampen, or control both the compression and rebound of the springs. With the coils on twin I-beams, the shocks are particularly critical to control suspension travel and minimize the camber change that takes place as the tires move up and down.

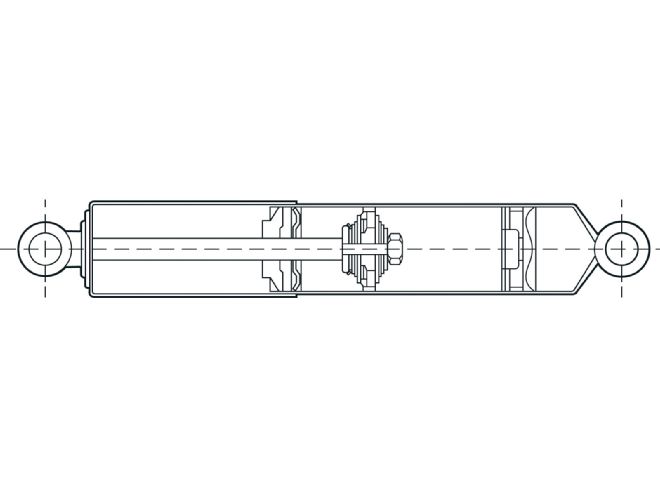

This is a cutaway of a Bilstien monotube shock. The larger piston of this design offers a number of advantages over the twin-tube design.

This is a cutaway of a Bilstien monotube shock. The larger piston of this design offers a number of advantages over the twin-tube design.

To understand how a shock absorber works, picture a piston with holes in it pushing against oil in a cylinder. As a liquid won’t compress, the oil will be forced through the holes slowing down the movement of the piston, the number and size of the holes will dictate how much oil can flow and how fast the piston can move. In a shock absorber this happens on both compression and extension, or rebound. The holes, or orifices, in the piston are directional, which allow them to be sized differently so there may be more resistance in one direction than the other. In addition, modern shock absorbers are velocity sensitive, which means the faster the suspension moves, the more resistance the shock absorber provides.

Got Gas?

Because there is some air inside a shock absorber, rapid movement of the piston can cause foam to form, which results in considerably reduced damping on compression and rebound. To combat this many shocks use pressurized gas, which stops foam from forming and results in a shock absorber with consistent performance. There are two basic types of gas shocks, the mono-tube high-pressure style and twin-tube low-pressure shocks.

As its name implies, twin-tube shocks have two chambers: an inner and an outer tube. In this style shock, the piston moves up and down in the inner tube in the main supply of oil, the outer chamber contains additional oil and a low-pressure nitrogen gas charge of 100–150 psi.

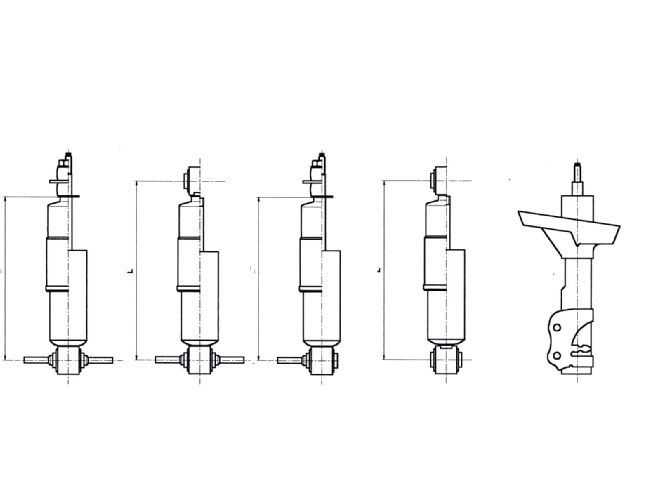

Bilstien shocks come in a variety of configurations: Left to right are pin and T-bar; loop and T-bar; pin and stud; loop and loop and strut.

Bilstien shocks come in a variety of configurations: Left to right are pin and T-bar; loop and T-bar; pin and stud; loop and loop and strut.

Twin-tube shocks are an improvement over totally hydraulic style, but they are still vulnerable to foaming and fade as the oil and gas mixes in extreme conditions. In our opinion, shocks on a twin I-beam Ford are operating in extreme conditions, which is why we opted to install Bilstein monotube gas shocks on the Hot Rod Hauler.

Bilstein’s monotube construction has a number of advantages over the twin-tube style. In a conventional twin-tube design, the majority of the oil is trapped inside the inner tube where the considerable amount of heat generated during operation is trapped, which leads to fade and markedly reduced effectiveness. With Bilstein’s monotube construction, the heat from the oil is transferred to the exterior of the shock body where it can be dissipated.

The monotube design has other advantages. Compared to the average twin-tube design, the Bilstein piston is a staggering 228-percent bigger, which allows more sensitive valving. Inside the tube is a “floating” dividing piston between the high-pressure nitrogen and the oil that eliminates any possibility of foaming and the resultant performance loss.

Below the piston that is attached to the rod, which is called the floater piston, can be seen. It separates the oil from the nitrogen charge, which prevents oil foaming, and shock fade.

Below the piston that is attached to the rod, which is called the floater piston, can be seen. It separates the oil from the nitrogen charge, which prevents oil foaming, and shock fade.

In some cases, such as our ’73 F-350, there may not be a listing for a replacement shock, but that doesn’t mean you can’t take advantage of Bilstein technology. All you’ll need to know are the top and bottom mounting styles along with the compressed, extended and installed lengths, then contact a Bilstein dealer. For a listing check www.bilstein.com.