As automotive enthusiasts, we often talk about the different methods of making engine power, as much of our interest lies under the hood of our Mopars. The pros and cons of automatic versus manual transmissions are also a subject of our conversations, as are the various ways to get our cars to run quicker elapsed times, or make more power on the dyno. When it comes to the rear differential in our Mopars, however, most of us are aware that gear ratio selection is an important factor determining how a car will perform, but aside from that we have very little understanding of how the differential actually works.

We've all likely swapped rear ends without thinking much about what it takes to build a differential that can handle the abuse of a powerful Mopar engine. This month we'll discuss a critical part of your car's drivetrain, the rear differential, and show you how to build and install your 8 3/4 rear end the right way.

We've all likely swapped rear ends without thinking much about what it takes to build a differential that can handle the abuse of a powerful Mopar engine. This month we'll discuss a critical part of your car's drivetrain, the rear differential, and show you how to build and install your 8 3/4 rear end the right way.

Since most of our Mopars came with the Chrysler 8 3/4 rear end, we seldom have any major problems with this area of the car. In fact, even a factory 8 3/4 can handle substantial engine power without fatigue, and we've seen high-mileage rear ends handle modified big-blocks without much trouble. So, barring a catastrophic failure of the rear end, we generally just tend to forget about how many parts are in the rear differential and the various ways they can wear out, negatively affecting the performance of our vehicles. Worn ring and pinion gears will whine, and more serious problems will cause vibrations, excess drag, and even rear end lockup.

Installing the components necessary to build a rear differential requires special tools and expertise. We've done it before, but this time decided to rely on Randy's Ring and Pinion to build a stout 8 3/4 centersection using all new parts. (Somewhere a high school is missing a cafeteria tray.)

Installing the components necessary to build a rear differential requires special tools and expertise. We've done it before, but this time decided to rely on Randy's Ring and Pinion to build a stout 8 3/4 centersection using all new parts. (Somewhere a high school is missing a cafeteria tray.)

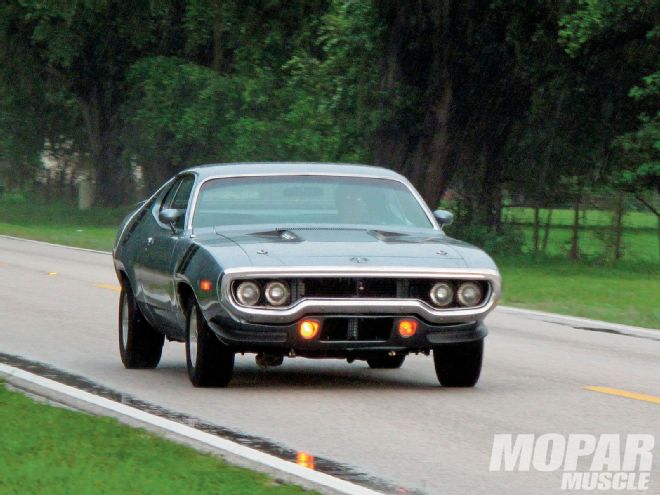

Swapping the rear end for another used one is an option, and most of us have swapped the centersection of our 8 3/4 to gain more optimal gearing as well. But as even the most recently produced factory 8 3/4 rear ends are 30 or more years old, the centersection you find to install in your car may be just as worn as the one you removed. Thankfully, most 8 3/4 differentials can be rebuilt, and many new parts are available. Since we needed a solid rear for our '71 Road Runner, we contacted Randy's Ring and Pinion to check out our options for the 8 3/4 in our car.

Our Road Runner is basically a street car that will see occasional track time on the weekends. With a four-speed and warmed over 383, we chose an Auburn Sure Grip and 3.55 ratio gears for our 8 3/4.

Our Road Runner is basically a street car that will see occasional track time on the weekends. With a four-speed and warmed over 383, we chose an Auburn Sure Grip and 3.55 ratio gears for our 8 3/4.

Like most Mopar enthusiasts, we like to perform much of the work on our cars ourselves. One area that we tend to leave to the experts, however, is the rear differential, and specifically the Sure Grip unit and ring and pinion gears of the car. It's not that the differential is beyond our technical expertise so much as this type of work requires specialty tools and must be done correctly so that the rear end has minimal drag and the appropriate amount of gear noise for the application. For these reasons, we decided to let the pros at Randy's Ring and Pinion build our 8 3/4 centersection, and we followed along to show you how it's done the right way.

Randy's Ring and Pinion stocks all the parts necessary to build an 8 3/4 centersection, and even has new aluminum housings for extreme applications. We chose a factory 742 case that they have thoroughly inspected and cleaned for our street car.

Randy's Ring and Pinion stocks all the parts necessary to build an 8 3/4 centersection, and even has new aluminum housings for extreme applications. We chose a factory 742 case that they have thoroughly inspected and cleaned for our street car.

When choosing a rear differential, the first determination that must be made is the intention of the car. For all-out drag cars with slicks that don't see street duty, a spool (solid) rear axle makes the most sense. The spool is lighter and locks the rear axles together, ensuring both tires spin at equal rpm at all times. At the other end of the spectrum, if you're just replacing the rear in your '74 Dart four-door with a Slant-Six, an inexpensive open style unit will work just fine. For the majority of us, however, a limited-slip type differential is the best choice for our street cars, or even cars that see a blend of street and strip duty. Chrysler called their limited-slip differentials Sure Grip and they were used extensively in muscle cars, trucks, and even station wagons.

After cleaning all the new parts, a first step prior to assembly is to make sure the back of the ring gear is flat and free of machining burrs that can happen when the bolt holes are drilled and tapped.

After cleaning all the new parts, a first step prior to assembly is to make sure the back of the ring gear is flat and free of machining burrs that can happen when the bolt holes are drilled and tapped.

There are several versions of the 8 3/4 centersection, and up until the mid-'60s, the differential had a bolt-together pinion yoke, making those undesirable for performance builds. The most common casting numbers for the 8 3/4 centersections end in the numbers 741, 742, and 489, with the 741 case being the least desirable due to its small diameter pinion bearing. Inside the cases, there were two types of Chrysler Sure Grip, commonly called the clutch style and the cone style, used to apply power to both axles during hard acceleration, but let the inside axle slip to maintain control when cornering. Both of these differentials worked well, but the clutch style is considered better of the factory Sure Grips because of its simpler design and its ability to be rebuilt when worn out. And speaking of wearing out, any factory 8 3/4 that has been used extensively, especially in a muscle car, is likely worn out by now. Since the rear in our Road Runner was suffering multiple ailments, including gear whine and chatter during tight turns, we decided to replace it.

We chose a billet yoke that utilizes U-bolts instead of straps to hold the universal joint in place. The factory yokes and straps were a weak link, and this eliminates them from our combination.

We chose a billet yoke that utilizes U-bolts instead of straps to hold the universal joint in place. The factory yokes and straps were a weak link, and this eliminates them from our combination.

Because our Road Runner will see mostly street driving, with some aggressive driving thrown in during weekend trips to the dragstrip, we decided that a Sure Grip unit would be the perfect choice for our B-Body. Additionally, since our A-833 four-speed transmission ends in a one-to-one ratio (no overdrive), we needed a set of gears that would allow highway cruising, counting on the relatively low first gear of the four-speed to get our weighty B-Body out of the hole. Knowing we're planning a future engine change to a larger and more powerful engine than the 383 currently in the car, and having experience driving cars with a multitude of engine and gear combinations, we decided that a 3.55 gear ratio would be about right. This gear ratio is a bit of a compromise on both ends, sacrificing a little bottom end and a little top speed, but is a great all-around gear that will allow us to drive the speed limit on the interstate while keeping our engine at a reasonable rpm.

With our decision made, we called Randy's Ring and Pinion to see what our options were. Building rear differentials for everything from industrial applications to all-out high-horsepower racing vehicles, the team at Randy's has good experience and quickly suggested, although they did have aluminum centersections for the 8 3/4, that we should build a differential using a factory 742 case for our application. Inside, Randy's installed a new Auburn Sure Grip unit, new heavy-duty 3.55 ratio ring and pinion set, and all new bearings and seals. Additionally, we chose to install a billet pinion yoke, taking away the weak link of the somewhat brittle factory yoke.

Silicone sealer does work OK here, but using the correct gasket is a better choice.

Silicone sealer does work OK here, but using the correct gasket is a better choice.

Once ordered, Randy's Ring and Pinion shipped the completed centersection directly to us, and local shop Inline Performance Specialists was nice enough to let us use one of their lifts to install it. The difference? We'll just say dramatic. The new differential is far quieter than our worn out 3.91 geared 489 case factory rear, and we even took away an annoying vibration that we later found was caused by a worn pinion bearing in the unit we removed. Even better than our newfound smooth and quiet operation, the 3.55 gears allow us to cruise at highway speeds without excessively revving the engine. Not bad for a phone call and a couple of hours on the lift.