Brand loyalty runs deep, but it's hard to deny that the other guys make some good stuff from time to time. Why else would hot rodders bolt Ford rearends beneath Chevys, GM transmissions behind Ford engines, and Chrysler Hemis into AMCs? With all due respect to the competent GM 12-bolt and legendary Ford 9-inch, Chrysler's Dana 60 is the mother of all rearends. This absurdly robust driveline specimen was originally designed for heavy-duty military vehicles during World War II, and was adapted for street combat in the '60s by Chrysler to endure the fury unleashed by its Hemi- and 440-powered muscle cars. We're currently busy putting the finishing touches on a built 455 big-block for our '65 Olds Cutlass project car, but its projected 500 hp is respectable rather than incredible. As such, our original plans called for replacing the factory 10-bolt rearend with a 12-bolt, but when Strange informed us that it offers a big-inch Dana 60 for GM A-bodies, we were more than intrigued.

Without question, nothing embodies overkill more than installing a Dana 60 in a 500hp street machine. Nonetheless, its benefits over both a 12-bolt and 9-inch made the decision a no-brainer. What makes the Dana 60 so good are its massive 9.75-inch ring gear, 35-spline axles, heavy-duty cast centersection, and 3.125-inch diameter axle tubes. In comparison, factory GM 12-bolts incorporate 8.875-inch ring gears, 30-spline axles, and 3-inch axle tubes. Stock Ford 9-inch rearends, on the other hand, make do with 9-inch ring gears, 28- or 31-spline axles, and 3-inch axle tubes. Granted, bigger aftermarket axles can be easily swapped into the 12-bolt and 9-inch, but bigger ring gears cannot.

Consequently, even in stock trim the Dana 60 can handle nearly 1,000 hp. Despite its strength, it's actually more efficient than a 9-inch, and only takes slightly more power to turn than a 12-bolt. Of course, there's a weight penalty that goes along with this stout of a rearend, but it's entirely reasonable considering its indestructible nature. The Dana 60 weighs just 15 pounds more than a 9-inch, and 25 pounds more than a 12-bolt. The real kicker, however, is that Strange sells complete ready-to-bolt-in Dana 60 rearends for $1,995, which is actually less than a comparable 9-inch or 12-bolt. Strange offers them for GM A-, F-, and G-bodies as well as GM and Mopar leaf-spring muscle cars.

As good as a stock Dana 60 may be, Strange has figured out how to make it even better. With core rearends in short supply, Strange came up with its own proprietary housing design called the S60. It's essentially a new and improved Dana 60 rearend that doesn't use any original Dana 60 components. The S60's centersection is cast from rugged nodular iron, and features main caps that are much larger than stock. Other enhancements over a factory Dana 60 include fully welded axle tubes and adjuster nuts for easy backlash adjustment. In addition to the aforementioned features, every S60 rearend assembly comes equipped with either 35- or 40-spline axles, 3.150-inch housing ends, 1/2- or 5/8-inch wheels studs, a differential cover/brace, a 1350 pinion yoke, a ring-and-pinion set, and your choice of a limited-slip differential or a spool.To get a closer look at the S60 rearend, we spent a day with John Kwas of Strange Engineering as he put one together for Project Olds. We then made a stop at D&Z Customs in Kewaskum, Wisconsin, where Randy Johnson performed the rearend swap on Project Olds.

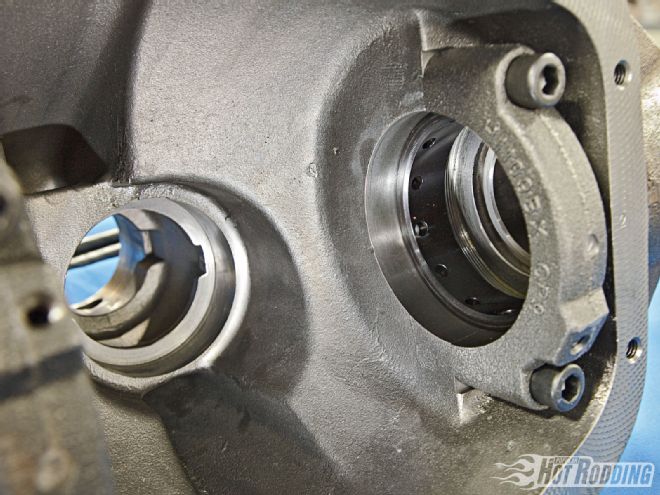

In a factory Dana 60, material has been removed throughout the inside of the centersection as well as the area beneath the main cap supports, presumably to reduce weight. While few people have succeeded in breaking a stock Dana 60, shaving the centersection in such a manner doesn't do much for strength.

Instead of removing material from inside the centersection, Strange improves upon the original Dana 60 design by adding reinforcement ribs on the inside, and shaving material off of the outside of the case. Overall, the S60 case is thicker than the factory unit, and the main cap support area has been beefed up as well. The entire S60 case is cast from premium high-strength nodular iron.

Unlike a stock Dana 60 where the axle tubes are merely pressed and plug welded to the centersection, the S60 features welds around the entire perimeter of the axle tubes. This prevents the axle tubes from rotating inside the case, and eliminates oil leaks as well.

Strange offers both 35- and 40-spline axles with its S60 rearend packages. Consider that even the 35-spline axles offer more than double the strength our application requires, we opted for the smaller of the two options. The S/T axles are forged from an induction-hardened 1550 steel alloy Strange calls Hy-Tuf, which features a high nickel content to withstand big torque and bending loads. Rugged 1/2-inch wheels studs are also included.

Rounding out the S60's guts are a set of 3.73:1 gears, a 1350 steel pinion yoke, Timken bearings, and a Strange limited-slip differential. Standard limited-slips wear out their clutch packs over time, but the Strange design is a worm gear-based unit that eliminates wear, and provides an extremely progressive transfer of torque from side to side. Another advantage of the Dana/S60 is that it enables running a limited-slip with beefy 35-spline axles. Anything beyond 33-spline axles in a 12-bolt and 31-spline axles in a 9-inch requires stepping up to a locker or a spool.

With decades of experience under its belt, Strange has concluded that when a rearend whines, the pinion gear is usually the culprit. This is because it takes most of the beating during the assembly and manufacturing process. To combat potential noise issues, Kwas chamfered the pinion teeth to eliminate any sharp edges.

Polishing down the pinion gearshaft on a lathe is a standard OE manufacturing procedure, and Strange implements the practice as well. This enables the pinion bearing to be pressed on with minimal effort. Since the bearing may need to be pulled on and off several times during assembly to properly shim the pinion, polishing the pinion shaft reduces the chances of damaging it.

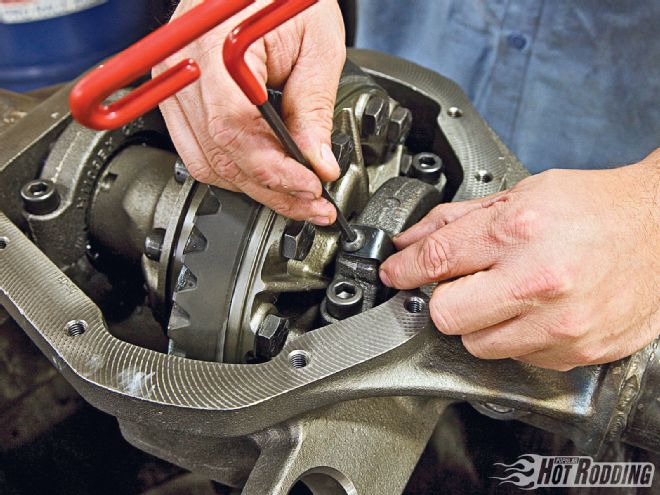

After pressing on the carrier bearings, it was time to install the ring gear. Instead of drawing the ring gear down to the differential by tightening up the bolts, Kwas prefers pressing it on. Using a large cylindrical slug of aluminum on the bottom of the press allows evenly distributing force on the ring gear face, reducing the potential of damaging the gear. Afterward, the ring gear bolts were torqued to 120 lb-ft.

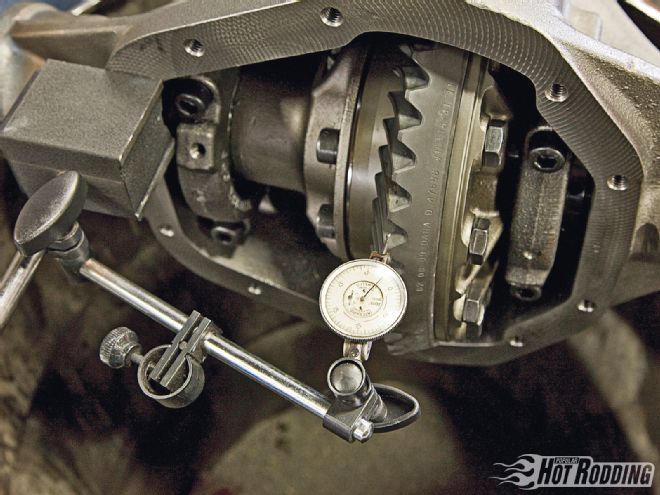

Setting up backlash is typically a cumbersome and time-consuming process that involves shimming the carrier assembly to adjust the depth at which the pinion engages into ring gear. The S60's adjuster nuts thread into the centersection, and can be moved in and out with a spanner wrench to quickly and precisely dial-in backlash.

Achieving the ideal wear pattern on the ring gear requires shimming the face of the pinion gear at just the right distance from the axle centerline. Kwas says the S60 usually needs a shim between 0.010- to 0.025-inch thick. He installed a 0.015-inch shim as a starting point before sliding the pinion into the case.

The S60's main bearing caps are twice as thick as the caps on a standard Dana 60. They were torqued down to 85 lb-ft before finalizing the backlash and pinion depth.

Another benefit of the S60's adjuster nuts is that it offers a wider range of backlash adjustment. Kwas set it up at 0.005 inch.

The baseline 0.015-inch shim yielded a wear pattern that was a hair too close to the outside of the ring gear. Switching it out for a thicker 0.020-inch shim centered the pattern right up.

The S60 uses pre-loaded pinion bearing shims, which eliminates the need for a crush sleeve. After removing all free-play with an impact gun, all it takes is 20-25 lb/in to seat the pinion seal.

To ensure that the adjuster nuts and backlash stays put, the S60 features lock tabs that bolt to the main caps. Should the backlash ever need to be changed after installing the rearend in a car, it can easily be adjusted without disassembling the entire rearend.

Strange technicians etch their John Hancock and date of assembly into the ring gear of every rearend they build. It's just one example of the company's commitment to quality.

The S60's 3.150-inch axle housing ends are large enough to accommodate both the axle bearing and race inside the axle tube. This arrangement also allows anchoring the axles to the rearend housing using retainer plates. Not only does this prevent the axle from ejecting outward in the event of an axle failure, the retainer plate setup is less prone to leaking oil than a rearend that uses C-clip eliminators.

After applying a layer of silicone, Kwas bolted down the S60's handsome differential cover. Although it's ribbed for enhanced strength, since the S60 has such large main caps that experience little to no deflection under load, an integrated brace (to preload the caps) isn't necessary.

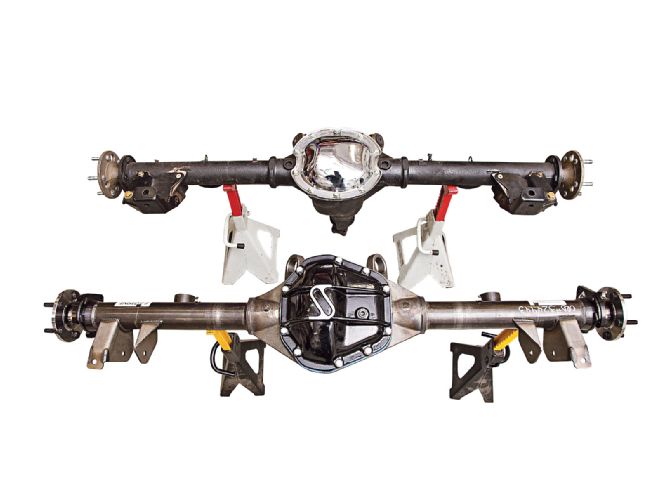

Compared to the S60, the factory 10-bolt originally equipped on Project Olds looks absolutely diminutive. The difference in the size of the centersections is quite revealing.

The S60 is equipped with control arm brackets, and spring and shock mounts that are compatible with '64-72 GM A-bodies. Since we already installed a Detroit Speed and Engineering coilover conversion kit on Project Olds, the coilover bracket had to be removed from the 10-bolt, and installed onto the S60. Afterward, the new rearend was spray painted black.

The previously installed DSE rear suspension kit and Baer disc brakes swapped over to the S60 without a hitch. Thanks go to Randy Johnson of D&Z Customs for turning the wrenches.

With the S60 anchored beneath the Cutlass, it was topped off with Lucas heavy-duty 85W-140 gear oil. To properly break in the new gears, Strange recommends allowing the rearend to cool after each 50-mile drive for the first 200 miles.

So we can drive around temporarily until the big-block and five-speed get dropped into place, we shortened up the stock driveshaft 1.5 inches and installed a set of 1350 U-joints.

WHERE THE MONEY WENT Item: PN: Price: Strange S60 rearend PRSA05 $1,995 Strange differential upgrade OPRS02 $300 Total: $2,295

THE COST SO FAR Description: PHR Issue: Price: '65 Olds Cutlass January 2010 $7,500 DSE four-link suspension January 2010 $2,345 DSE front suspension February 2010 $3,982 Baer front and rear brakes March 2010 $2,670 DSE brake booster March 2010 $375 DSE steering kit April 2010 $399 Strange S60 rearend May 2010 $2,295 Total: $19,566