For stock class racing, making gear changes at the track may not be feasible. But many teams keep several assembled rearends handy with different ratios for running different racetracks.

For stock class racing, making gear changes at the track may not be feasible. But many teams keep several assembled rearends handy with different ratios for running different racetracks.

We need to choose the correct gear for our particular racing and track configuration, and we need to maintain that overall ratio when we make changes. Finding the right gear ratio for a particular track in a certain class of circle track racing may be as easy as asking your competitors. Most racers who regularly run the same racetrack each week will settle on the same gear and run it the entire season. But is the gear you are using producing the fastest lap? And, what if the track requires a different tire than last year? Here's how you can keep straight with your gear choices.

Differences in the track length and shape, tire sizes, class rules, and other factors can cause us to rethink our selection of gears, possibly from week to week and even beginning to end of an event in the case of dirt-track racing. The reasons for this may become more apparent as we study the whole concept of gear selection.

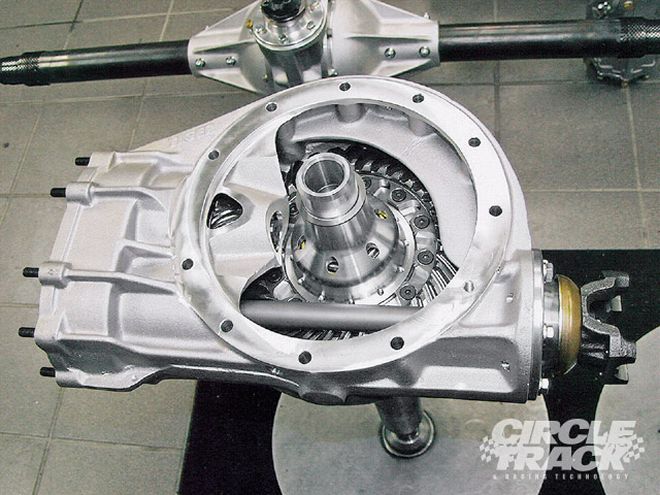

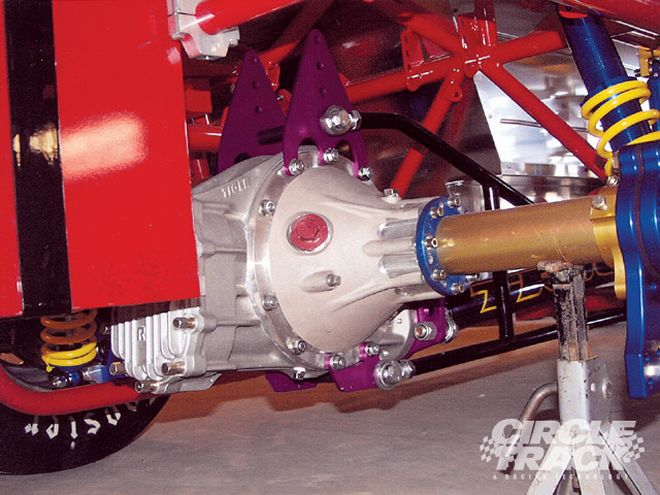

There are two basic rearends that are used in circle track racing. There is the OEM-type ring and pinion in a pumpkin case, where gear changes are rather difficult and racers are less likely to make week to week changes. The other is the quick change-type rearend, which is designed to be much easier to access the drive gears and therefore facilitate quick changes to your gear ratio. The reasons why we would make these changes are varied, but in many cases necessary in order to maintain performance levels.

Quick change and not-so-quick change rearends both need to have the correct gear ratio in order to have maximum performance.

Quick change and not-so-quick change rearends both need to have the correct gear ratio in order to have maximum performance.

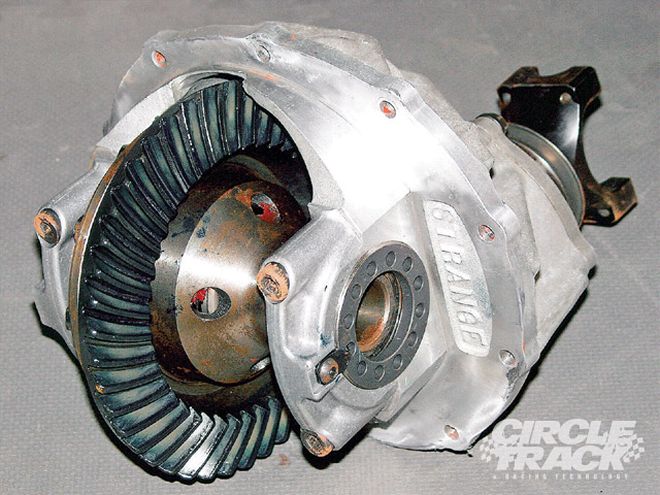

To say that the quick change is superior would not be exactly accurate. It is in fact less durable than the OEM-type rearend for higher horsepower applications, but for most short-track racing, holds up fine with regular maintenance. For larger cars that run long and fast racetracks and with high horsepower engines at high rpm, the Ford 9-inch based rearend is almost mandatory.

For our discussion, we'll use the quick change rearend as an example. Some of the discussion will also relate to the OEM rearends as we talk about reasons for gear change, not necessarily the process of making those changes as involved with each type. The OEM rearends are built to a specific gear ratio and are carefully matched so that the pinion and ring gears are meshed correctly. This unit is changed out to make gear changes to the car. It's simply a matter of switching third members and a team must have several of these units assembled and ready to install.

This is a rearend gearset that is based on the Ford 9-inch rearend. It's durable enough for high horsepower applications. It's not easy to change at the track. Professional teams keep many sets of these units on the trailer in case they need to change their gear ratios.

This is a rearend gearset that is based on the Ford 9-inch rearend. It's durable enough for high horsepower applications. It's not easy to change at the track. Professional teams keep many sets of these units on the trailer in case they need to change their gear ratios.

We should always know and consider the highest and lowest rpm in our power band when choosing the gear for our cars. You need to know where the useful engine power band starts and ends for your motor. Then look at what the engine rpms are at each point around the track for the gear you are currently running. You don't want to begin to accelerate off a turn below the rpm where the power starts to build and/or the torque is near peak.

Likewise, it may not be the best idea to run out of the power band somewhere down the straightaway. A bigger mistake might be to begin to hit peak horsepower just as you are getting ready to brake into the corner. There is a compromise that may produce a faster lap.

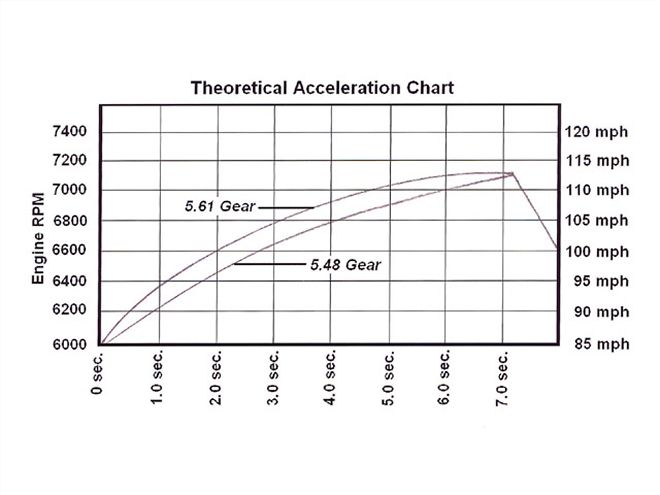

There may be two or more gear ratios that will produce the same rpm at the lift point at the end of the straightaway. Each will begin at the same rpm off the turns and each will end at the same rpm at the lift point going into the next turn, but one will be faster. How so? Here's how.

In this exaggerated example, we can see where the use of a lower 5.61 gear over a 5.48 gear might improve acceleration while showing the same rpm at the end of the straightaway. Looking at 6,800 rpm, we see where we reached that speed approximately 0.8 seconds sooner with the 5.61 gear. The real gains will be smaller, but still significant. Notice how the 5.61 speed gain trails off towards the end of the straightaway but is still higher than with the 5.48 gear at 7,200 rpm.

In this exaggerated example, we can see where the use of a lower 5.61 gear over a 5.48 gear might improve acceleration while showing the same rpm at the end of the straightaway. Looking at 6,800 rpm, we see where we reached that speed approximately 0.8 seconds sooner with the 5.61 gear. The real gains will be smaller, but still significant. Notice how the 5.61 speed gain trails off towards the end of the straightaway but is still higher than with the 5.48 gear at 7,200 rpm.

If we chose a gear that will pull from say 5,000 rpm just past mid-turn to 7,100 rpm at the end of the straightaway, we might feel we have the right gear if the horsepower curve goals are met. That means our engine hp curve comes on at 5,000 rpm and it peaks at 7,100 rpm. It sounds like we have the right gear, but maybe not.

On some tracks where acceleration off the corners is critical for passing, a lower gear (higher ratio) might help us get off the turns better while not necessarily hurting us at the other end. The lower gear will accelerate the car quicker and if we don't lose traction with the switch, at least to the flag stand, we'll be better off.

For the last half of the straightaway, if we have gained a half a car length by now, our speed will be mostly peaked while our competitor will still be accelerating. We'll still be pulling away from the other car because the other car has not yet reached top speed/rpm.

Our turn entry will be much smoother because we will have reduced our acceleration before we lift to brake while the other car is still accelerating when the transition to braking occurs. It's very disruptive to make the change from hard acceleration to hard braking. It's much smoother to transition from steady speed to hard braking. Just ask any high performance driving instructor and he or she will agree.

Gear changes with the OEM-type of rearend are harder than the quick change rearend, but doing a little experimentation might be well worth the effort to obtain maximum performance.

Gear changes with the OEM-type of rearend are harder than the quick change rearend, but doing a little experimentation might be well worth the effort to obtain maximum performance.

So, we might be better off to install a lower gear, beat our competition off the corner and have a better corner entry all by doing a little experimentation. All it takes is a little effort and testing with a stop watch and the results can be evaluated. Most teams don't know what areas to test at a test session. This is one of those areas that may well improve your performance. Just work your stop watch from the mid-turn to the lift point at the end of the straight.

A lower gear will pull much better, but only if the engine is putting out sufficient horsepower at the low end, and if you can get the pulling power to the racetrack. Being able to pull great off the corner is all lost if the wheels end up slipping. So, make sure you can tighten the car off the corners sufficiently to take advantage of the lower gear.

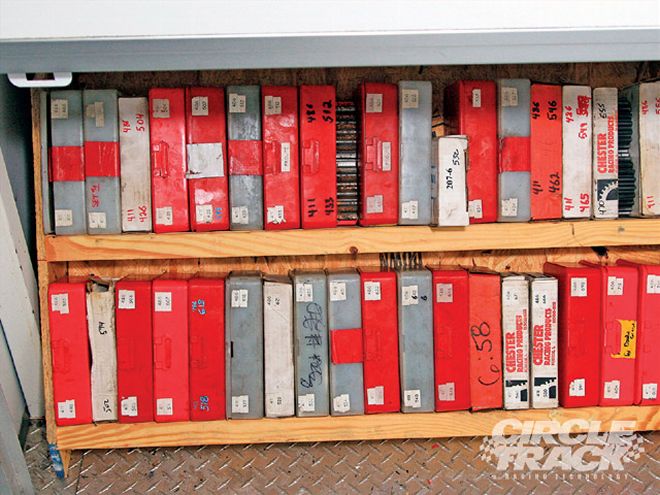

Some teams label their gear sets clearly so that when it comes time to make a change, any crewmember can easily find and produce the needed gear set.

Some teams label their gear sets clearly so that when it comes time to make a change, any crewmember can easily find and produce the needed gear set.

This is true especially for dirt racers running on dry, slick tracks. But for most dirt tracks the condition of the track is constantly changing. If we know the track is going to have much more bite early in the event, during qualifying and on into the early heat races, we might be able to use that to our advantage when selecting gears.

When the track is tight, we can utilize a lower gear since we will have more traction available. If the other cars still have their higher ratio gear in the car that work best under the dry slick conditions that will come later on in the evening, we might qualify better and run better in the heat race. That will get us a much better starting position for the main event.

If the track has gone dry and slick, we can then make a gear change to a higher gear that is less prone to spinning the tires to maintain grip off the corners. Power availability at the other end of the straightaway becomes less important on dry slick tracks. Many top Late Model touring drivers have been heard to say they often used no more than half throttle for the whole race for many of their wins on dry slick tracks.

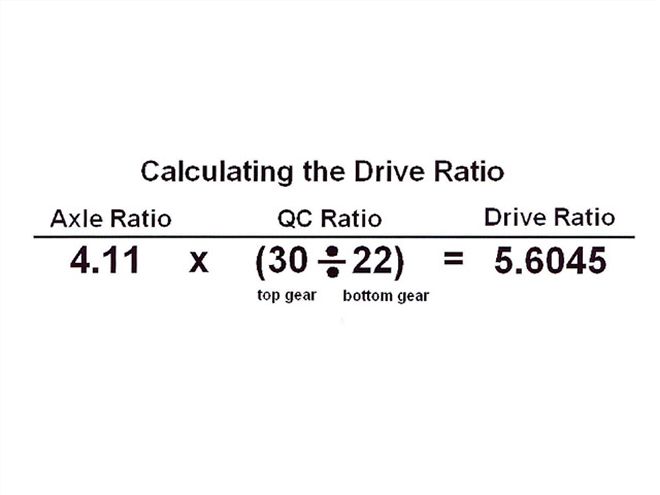

To calculate the Drive Ratio for a quick change, divide the number of teeth in the top gear by the teeth in the bottom gear for the QC ratio, multiply that by the axle ratio (ring and pinion ratio of the QC rearend) and you have the Drive Ratio. For OEM-type rearends, you divide the number of teeth in the ring gear by the number of teeth in the pinion gear for the Drive Ratio.

To calculate the Drive Ratio for a quick change, divide the number of teeth in the top gear by the teeth in the bottom gear for the QC ratio, multiply that by the axle ratio (ring and pinion ratio of the QC rearend) and you have the Drive Ratio. For OEM-type rearends, you divide the number of teeth in the ring gear by the number of teeth in the pinion gear for the Drive Ratio.

If you go to a lower gear and put yourself way beyond the point where the motor produces good horsepower half way down the straightaway, you've probably gone backwards. Restricted motors are especially known for a dramatic drop in hp at the end of the power band. Not only is the power band running out, but also the restricted intake won't suck any more air at the higher rpm.

For the longer tracks of 3/4 mile or longer, using a higher gear might produce more top speed for a larger gain since we stay at the elevated speed longer on those tracks and acceleration is not a significant factor.

This is where the thinking that higher rpm produces higher horsepower may be wrong. Torque is a factor in producing a higher top speed and the torque curve may fall off before the hp curve does. Gearing for maximum torque may produce a higher top speed on longer racetracks. Many teams have been both fooled and surprised by gear changes that produced different results than were anticipated.

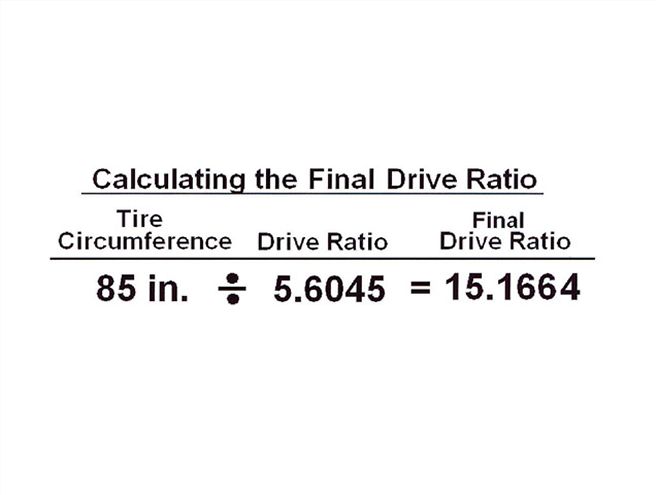

To calculate the Final Drive Ratio that includes the tire circumference, we divide the tire size in inches and decimals by the Drive Ratio to get the Final Drive Ratio. This number can be used to recalculate the correct gear that would go with a new sized tire.

To calculate the Final Drive Ratio that includes the tire circumference, we divide the tire size in inches and decimals by the Drive Ratio to get the Final Drive Ratio. This number can be used to recalculate the correct gear that would go with a new sized tire.

The best rule is to let the stopwatch determine the best gear. The fastest gear on the watch may not look or feel fast, but the lap times will tell the true story.

Divide the track into segments and time the car from the points on the track where the driver starts to accelerate to where the driver lifts going into the next turn. Use the exact same point on the racetrack for every measurement of elapsed time. Compare your times to your competitor's times to judge how each gear change stands up.

The common interpretation of Drive Ratio for a quick change (QC) rearend is the combined ratio of the axle ratio and the QC gear ratio. We prefer to call this the Drive Ratio. We will use the word "final" later to include the tire size used in combination with the gear ratios. To find the Drive Ratio, we multiply the QC ratio by the axle ratio to find the Drive Ratio.

The tire size affects our true Drive Ratio (DR). So, if we include the tire size into our calculations, we will have the whole enchilada. To find this Final Drive Ratio (FDR) number we divide the Drive Ratio into the tire circumference. If we have a 4.11 axle ratio, a 30 tooth over a 22 tooth QC ratio being 1.364, then our DR is 5.6045. If we then divide the DR into the tire circumference of, say, 85 inches, our FDR is 15.1663. This is a number we need to record and remember.

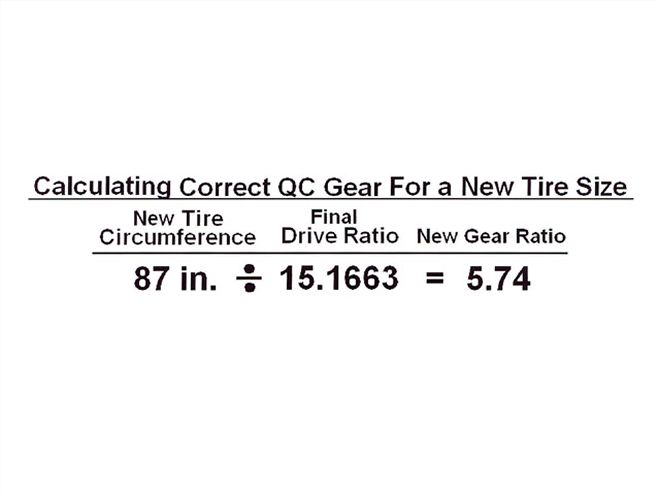

In this example, we have a new tire size of 87 inches in circumference, up from the 85 inch tire we had in the previous examples. To find the correct QC gear ratio to maintain our Final Drive Ratio, we divide the new tire size by our Final Drive Ratio to arrive at a 5.74 QC gear. If we install this gear, or one very close to it, we will maintain our previous performance.

In this example, we have a new tire size of 87 inches in circumference, up from the 85 inch tire we had in the previous examples. To find the correct QC gear ratio to maintain our Final Drive Ratio, we divide the new tire size by our Final Drive Ratio to arrive at a 5.74 QC gear. If we install this gear, or one very close to it, we will maintain our previous performance.

The reason this number is significant is because we might find ourselves having to use a different size tire some weekend down the road. Suppose for whatever reason we arrive at the track late and all that is left in the tire truck are 87 inch or larger tires. Do we need to make a gear change? You bet. Here's why.

If we do the math in reverse and divide our FDR number into 87 (the new tire size) we get a new DR of 5.74. That is what our rear gear should be in order to keep our same FDR at 15.1663. That means we need to install the closest gear to that, a 28 tooth over 20 tooth gearset equals a 5.76 QC gear to maintain our previous performance. If we don't make this change, the car may be flat off the turns and our lap times will suffer.

Always keep a record of your FDR. This is the ratio that includes tire circumference information. You may have found the right gear ratio for your track and then lose the advantage when you are forced to run different sized tires. This is especially true when a track changes tire brands where we have seen the sizes of each brand being different by two inches or more.

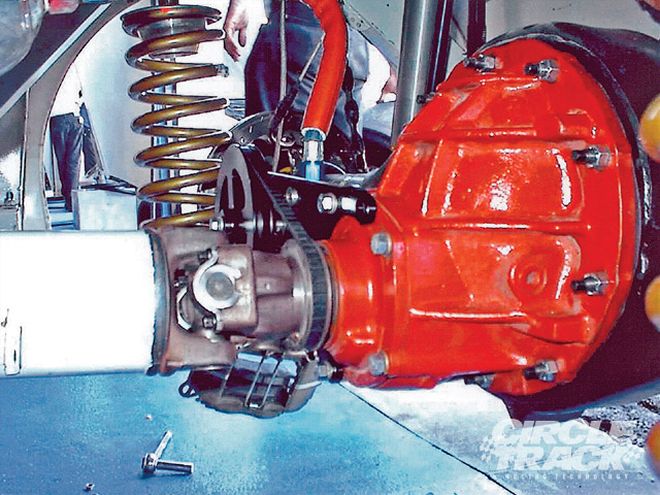

The Dirt Late Model cars are more open in the area around the rearend making gear changes easier than with some other designs of circle track cars. It may be well worth the effort to match the gear ratios to track conditions.

The Dirt Late Model cars are more open in the area around the rearend making gear changes easier than with some other designs of circle track cars. It may be well worth the effort to match the gear ratios to track conditions.

The right time to consider making a gear change might include: 1) when the track conditions change. This may be true for dirt or asphalt tracks. On dirt, it's obvious when the track changes, and for asphalt, temperature changes affect bite and gear choices, 2) when the tire sizes change, 3) when we go to a different racetrack that might be longer or shorter and/or have different tire sizes.

For dirt tracks, you might need to make two or three changes to your gear ratio depending on how much the track changes during the event. When the lap times change by 3-4 seconds, the lowest and highest speeds the car will attain will necessarily change. To keep the engine in the proper power band, gear changes must be made.

On asphalt tracks, hot summer temperatures make some tracks slick. A lower gear might produce more wheel spin and slow down lap times. A higher gear would allow more throttle application without tire spin. For the cooler months, a lower gear in combination with the added grip the track provides could produce better gains off the corner whereas the hot summer months might require a higher gear.

Always calculate your gear needs when changing rear tire sizes. A change in gear ratio equal to our example above represents a 150 rpm difference at 6,000 rpm. If you have dialed in just what you need for optimum lap times, maintain the FDR by making the necessary QC gear set change.

This rack of gears for a quick change rearend is neatly placed out of the way inside a race trailer. All of the gearsets that would ever be needed from a short quarter-mile track to a long one-mile track are here. All of the boxes are clearly marked so any crewmember can easily find and retrieve a needed ratio.

This rack of gears for a quick change rearend is neatly placed out of the way inside a race trailer. All of the gearsets that would ever be needed from a short quarter-mile track to a long one-mile track are here. All of the boxes are clearly marked so any crewmember can easily find and retrieve a needed ratio.

When we travel around to different racetracks, we need to consider several factors when selecting a gear. Gear needs are influenced by: 1) track length, 2) track banking angle (speed through the turns), 3) turn radius and length of straight-aways (tighter turns equal less speed and rpm, long straights equal high-end speed and rpm), 4) surface bite availability, especially for dirt tracks.

For longer tracks, we are less concerned about acceleration off the corners because the exit speeds are usually much higher than on shorter tracks. We can tune our gear selection to the rpm desired at the end of the straights.

Tracks with high banking angles will allow higher turn speeds, similar to what the longer tracks do. Therefore, our exit rpm will be higher and the added speed will be carried over the entire lap. The method of gearing slightly lower can be applied to shorter-length tracks with higher banking as well as longer, low-banked tracks. It will probably be more successful in this situation because with the higher banking and downforce created, traction off the corners will be less of a concern.

Gear selection and FDR maintenance are important and can improve your performance if done correctly. The math is simple and the process of finding the correct gear that will produce the quickest acceleration is a process best done during testing and with a stopwatch.

We have shown here that you can run different gear ratios and still end up with nearly the same beginning and ending rpm. So, shooting for just a rpm number may not lead us to the fastest gear. Don't neglect this tuning process that is a critical part of the overall performance package.