Not all oil filters are created equally, and they're not all easy to get to, either. Zailea lawrence gives her Grandpa Manny a helping hand getting to the remote spin-on on this Flathead-powered Model A.

Not all oil filters are created equally, and they're not all easy to get to, either. Zailea lawrence gives her Grandpa Manny a helping hand getting to the remote spin-on on this Flathead-powered Model A.

When you look at the average automobile, there aren't many parts on it that cost less than 10 bucks. You'd be even more hard-pressed to find something that cheap on a street rod; but just about every one of them has at least one-and it's the oil filter. Given what they do, oil filters are pretty cheap, but the "you get what you pay for" theory still rings true in this case.

For all practical purposes, oil filters can be broken into three categories: replaceable elements, cleanable elements, and (the most common) the spin-on, throwaway type. But, despite the type, the job they have is the same-remove as much contamination from the engine oil as possible. That contamination comes in three forms: solids in the form of debris from wear; liquids, such as fuel and water; and gaseous byproducts of combustion. But liquids and gas can cause corrosion and degrade the engine's lubricant, the solid particles that are larger than the oil film separating moving parts-90 percent of which are 10 microns in size or smaller, and they're what accelerate wear. Just to put things in perspective, 1 micron equals 0.00004-inch.

This is an AmsOil spin-on filter. Shown from left to right are the base gasket, base, silicone anti-drain back valve, end cap, full synthetic media, bypass valve (location varies), spring, and housing.

This is an AmsOil spin-on filter. Shown from left to right are the base gasket, base, silicone anti-drain back valve, end cap, full synthetic media, bypass valve (location varies), spring, and housing.

As you might expect, the more solid particles removed from the oil the better, and while there's no way to trap it all, testing has shown that compared to a 20- to 30-micron filter, a 10-micron filter reduces solid contaminants 10 to 15 times better. typical low-cost oil filters will trap about 40 percent of particles in the 8- to 10-micron range, while better filters catch about 72 percent of particles in the 8- to 10-micron range.

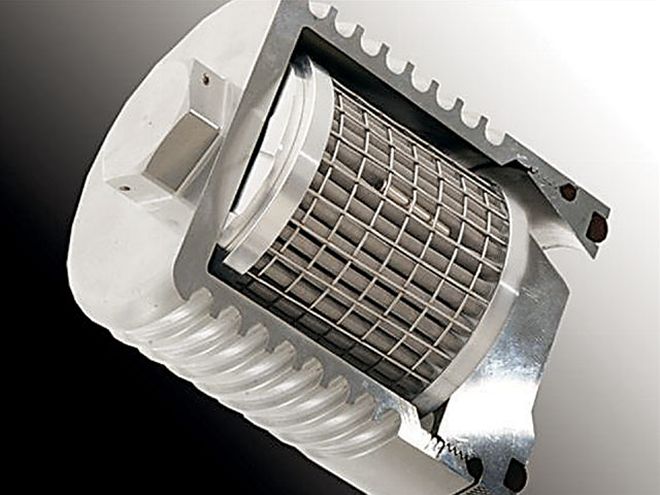

Spin-ons are certainly the most common type of oil filter and they're all built about the same-oil enters through the holes around the outside, goes through the media, and comes back out the center. the components consist of the base with a seal and a threaded hole that mounts the filter to the engine, and most have a one-way r anti-drain back valve that keeps dirty oil from running back into the engine when it's off; there is some sort of media that does the filtering; a bypass valve that lets oil circulate when the media is "full"; a spring that holds the components tightly together; and the canister that contains it all.

Speedway Motors sells this filter cutter; it's common for racers to open up filters to see what's ending up in there. in this case, it allows a good interior view. Note the cardboard end cap on this filter.

Speedway Motors sells this filter cutter; it's common for racers to open up filters to see what's ending up in there. in this case, it allows a good interior view. Note the cardboard end cap on this filter.

Filter Construction

Even though spin-on filters have similar parts, the quality varies dramatically; this is where you usually get what you pay for. some differences in the quality of oil filters can be observed, others are hard to detect. Baseplates. Compare the difference in baseplates, the sizes of the supply holes, and the number of threads in the center hole. some filters have mounting holes with very few threads and not many or small delivery passages. Drain Back Valves. inexpensive filters often use poorly designed plastic valves that are prone to leaking. Nitrile rubber is used in some, and while these are usually satisfactory, they may not seal in extremely cold weather (not normally an issue for street rods). Others are spring-loaded steel, and while the seal is metal-tometal, any seepage is usually minimal. in some cases, the drain back valves are visible through the supply holes, but not always. Metal valves are often at the bottom of the canister. Filtering Media. this is certainly one of the most important factors in filter effectiveness. Debris is trapped as oil passes through the media; the finer the passages in the media, the smaller the bits of debris are caught, but the trick is not to restrict oil flow at the same time. Paper is used in most inexpensive filters, which traps fewer particles and can flow less oil per square inch than other material because there are fewer passages through it-but it's cheap. Cotton is added to the paper elements to increase effectiveness in some filters, but a better media is made of synthetic fiber, which has smaller passages and as a result traps smaller particles while still passing more oil because there are more passages.

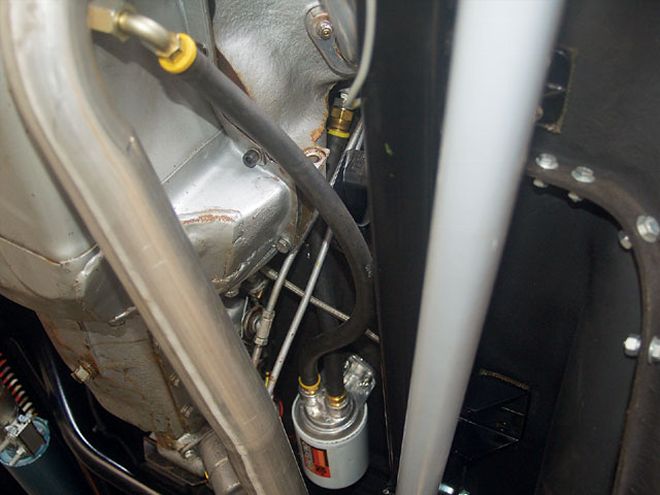

This Flathead has a full-flow filter system added to it. Oil is delivered from the pump through a bulkhead fitting in the pan, through the filter, then back to a fitting in the block.

This Flathead has a full-flow filter system added to it. Oil is delivered from the pump through a bulkhead fitting in the pan, through the filter, then back to a fitting in the block.

Whatever the filtering media used, it's normally pleated and wrapped around a support to hold it in place. some filters use metal supports while some inexpensive versions use cardboard. the ends of the pleats are glued or crimped together with a metal strip, and, if you ever cut a filter apart, you might find a string wrapped around the pleats to hold them during assembly. A common misconception is that the more pleats the better; however, more material may result in the pleats being packed in so tightly that oil flow is restricted; it takes a balance of the right type of material and the appropriate number of pleats.

A construction technique used in some of the better filters is "multidepth" media. Basically, the filtering material, usually synthetic, gets finer as the oil moves through it; large particles are trapped toward the outside, and smaller particles are caught farther in. Bypass Valve. the bypass valve opens when the filter isn't able to pass a suf- ficient volume of oil because the media is clogged, the oil is thick at startup, or the oil pressure is elevated due to high rpm. Of course, the oil supply isn't filtered when this happens, but that's a better option than starving the engine for lubricant or blowing apart the filter. Filter Body. even the most inexpensive filters have to pass sAe testing and should be able to cope with the oil pressure a street engine produces. some cases have extra features like a rough surface to make tightening by hand easier, or a nut-like protrusion on the end to facilitate removal.

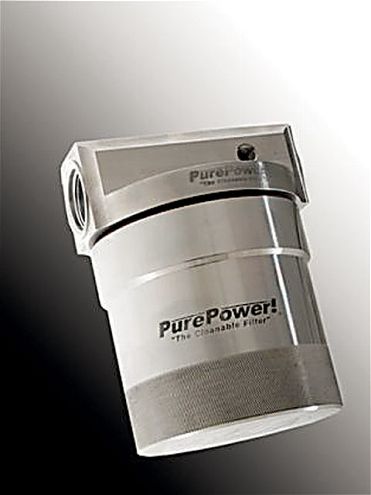

Pure Power! offers this beautifully constructed remote filter. Inside the spin-off canister is a cleanable, stainless steel element capable of trapping 10-micron-and-smaller particles. A unique patent-pending bypass valve is used.

Pure Power! offers this beautifully constructed remote filter. Inside the spin-off canister is a cleanable, stainless steel element capable of trapping 10-micron-and-smaller particles. A unique patent-pending bypass valve is used.

Cleanable Filters

While throwaway filters seem to be the norm, the cleanable variety is another option. Although the initial investment is usually more than a dozen or so spin-ons, there are a considerable number of benefits-the most obvious being that it's no longer necessary to deal with used filters. Most cleanable filters use stainless steel as a filtering media. some, like the Oberg, may have a simple flat screen; others, like those from Pure Power!, use a woven and pleated design.

As well as being effective, both from a filtering and long-term cost standpoint, cleanable filters also allow inspection of the type of debris being trapped, which can be a good indication of what's taking place inside the engine.

Bypass Filters

Another approach to filtration is adding a secondary bypass filter. Working in conjunction with the engine's full-flow oil filter, the AmsOil ea By-Pass Oil Filter system filters oil on a "partial-flow" basis. it draws approximately 10 percent of the oil pump's capacity at any one time and traps the extremely small, wear-causing contaminants full-flow filters can't remove.

Pure Power! also offers spin-on replacement filters with cleanable elements. The company offers the same filtering efficiency as the remote version, and they are easily cleaned with soap and water.

Pure Power! also offers spin-on replacement filters with cleanable elements. The company offers the same filtering efficiency as the remote version, and they are easily cleaned with soap and water.

Remote Filters

It's not unusual when swapping engines to find that the oil filter interferes with a chassis component or in someway complicates the installation -a situation that is easily recti-fied with a remotely mounted filter.As well as relocating for convenience,remote filters can be a means to retrofit engines that aren't equipped with one, or add better or multiple filters for increased effectiveness. Block-off plates with inlets and outlets are available for most engines to make moving the filter easy.

What To Choose

Filter manufacturers spend a huge amount of money advertising their products to convince consumers to by them; the trick is to ferret out the facts from the hype. look for references to the type of filtering media, how effective it is, compare the few features that can be seen, and keep in mind that you really do get what you pay for.

Oberg filters are found on a variety of race cars, and they come apart quickly so any debris trapped inside can be examined.

Oberg filters are found on a variety of race cars, and they come apart quickly so any debris trapped inside can be examined.

A Few Filter Faqs

Along with its well-know synthetic lubricants, AMsOil also offers a line of oil filters. We asked the company's ed Newman a few questions on the subject, and here's what he had to say.

How are filters rated?

Modern tests on typical spin-on filters are tested using isO method 4548-12. this test is designed to calculate the contaminant-removing effi ciency of filters using a specific particle size. Our filters were tested at 15 microns and are 98.7 percent effi cient at this level.

What size particles do damage to an engine?

in some cases, particle sizes as small as 1-5 um can cause damage; however, normally it is the 5-25-micron range that does the most damage to an engine.

What size particles do filters trap?Filters trap all particle sizes; it is the quality of media that is used that really dictates what particles get trapped and what particles go unfiltered.

What's the relationship between the size of a filter and its effectiveness?there are many different variables to take into account when designing filters in addition to filter size. Media type, pleat height, number of pleats, and other variables all need to be carefully controlled for proper filter design. linking size to effectiveness exclusively creates misleading generalizations.

How do oil filters affect oil pressure and volume?

Many different factors need to be accounted for when calculating normal pressure drop, but typical numbers for filters are up to 5 psi.