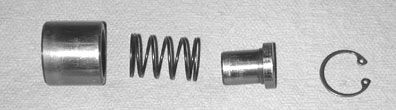

The governor assembly consists of an inner and outer weight and spring. The relative mass of the inner and outer weights and the spring tension all interact to determine the shift timing with a given assembly. Notice the lighter weights of the disassembled A&A governor (bottom) versus the stock governor (top). The spring tension is also revised.

The governor assembly consists of an inner and outer weight and spring. The relative mass of the inner and outer weights and the spring tension all interact to determine the shift timing with a given assembly. Notice the lighter weights of the disassembled A&A governor (bottom) versus the stock governor (top). The spring tension is also revised.

When Chrysler's 727 TorqueFlite resides in the tunnel under your machine, performance is automatic-or is it? After all, there are many modifications that can be made to a 727 to improve shift quality. The first step is a shift improver kit, and they're nothing new. In fact, there can be a tremendous difference in shift quality even between various factory 727s, depending upon the application. Hey, it doesn't take a Super Stock racer to discern the difference in the way a Hemi 'Flite bangs through the gears compared to a 727 in a Chrysler Newport; the shift quality is vastly different. While that Newport will glide through the gears almost seamlessly, an OE performance 727 will rip through the gears with precision bordering on brutal.

Today, a 727 for a performance application strives to capture the shift quality of the performance TorqueFlites of yesterday, or exceed it. We've covered the aforementioned shift kits in several articles over the years. Take your Newport tranny, add a shift kit, and if it does its job, which it should, that lazy transmission will take on a new personality. The next question becomes, "Will it last?" Now we're getting into questions of durability. Fortunately, most of the components that made the best TorqueFlites great can be incorporated into a weaker sibling 727 to beef it up. Without a doubt, there are components available to beef up the 727 to a far greater level than any OE tranny.

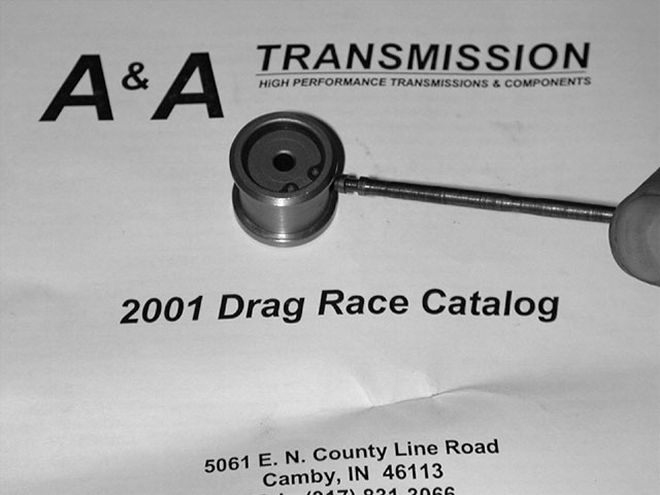

Governor kits from A&A come as preassembled governor weight sets, available at a variety of rpm ratings. We chose PN 22204-58, rated at 5,800 rpm. The rating is a nominal figure, and the actual shiftpoint will vary depending upon other transmission modifications and calibrations.

Governor kits from A&A come as preassembled governor weight sets, available at a variety of rpm ratings. We chose PN 22204-58, rated at 5,800 rpm. The rating is a nominal figure, and the actual shiftpoint will vary depending upon other transmission modifications and calibrations.

As we saw in Mopar Muscle last June ("Into the Slush Box," p. 58), beefing up a TorqueFlite requires extensive disassembly, if not a full rebuild with HD components. More and better clutches in roomier drums, ridged bands, locked down overrunning clutches (sprag), H/D planetaries, earlier kickdown servos, etc. Such a rebuild may not be too far in the offing if a powerful engine is pressing against that shift-kitted Newport tranny.

OK, shift quality and durability are both characteristics we seek to improve, but is that all? Another aspect of TorqueFlite performance worthy of consideration is shift timing. If you're making the serious move to a full manual valvebody, then shift timing is literally in your hands. However, if automatic function is not to be sacrificed, then shift timing becomes a significant element in how well the transmission performs in a performance setting.

On the most basic level, a component of shift timing is the operational line pressure of the transmission. Increase this line pressure, and the shift speed will also increase. Most shift kits, as part of their modification program, instruct the TorqueFlite tuner to increase the line pressure by cranking up the line pressure adjustment screw on the valvebody. This increases the tension on the regulator valve spring, in turn increasing the pressure, which firms up the shifts and raises the shift point. Shift timing, however, is only mildly affected by this mod; typically, OE trannys will still shift in the mid to upper 4,000 rpm range. The adjuster only gives so much latitude before the screw will literally run out of a safe level of engagement. Fortunately, there are other components that affect shift timing more directly than the line pressure. Primarily, this is the jurisdiction of the governor.

Far removed from the vicinity of the valvebody and making its home outside the main transmission case, in the extension housing, is the governor assembly. Operating within a housing on the output shaft, the governor is a hydraulic control valve that transmits regulated pressure to the valvebody directing the shift points. The governor assembly consists of a hydraulic control valve linked by a shaft to the governor weight assembly, made up of an inner and outer weight and spring. Here is the heart of shift timing in automatic mode.

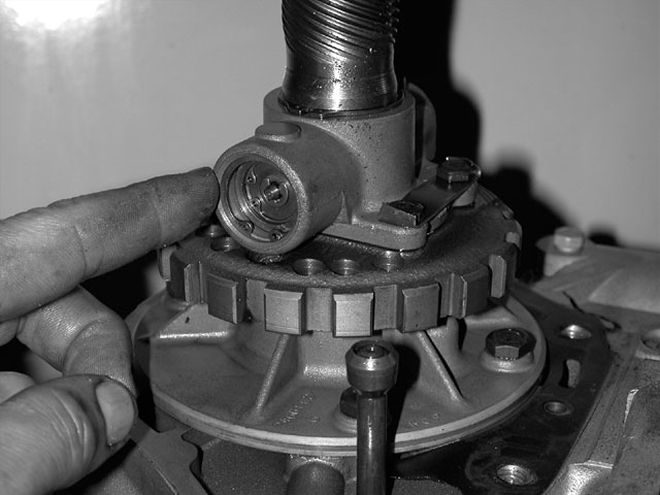

Inside, we find the governor housing, just to the rear of the parking gear.

Inside, we find the governor housing, just to the rear of the parking gear.

As usual, Chrysler didn't take a one-size-fits-all approach to 727 governors, varying these components for particular upshift speed requirements. The balance of inner and outer weights and spring tension determine the shift point for various governor assemblies. To increase the shift speed, the stock governors can be modified by reducing the weight and/or increasing the spring tension. That's work that requires a lathe, knowledge, and a trial-and-error process to dial in. An alternative is the wide range of preassembled high-speed governor assemblies offered by A&A Transmissions in Camby, Indiana. A&A carries governor assemblies rated in 200-rpm increments from 5,000-6,000-plus rpm, offering an easy way to optimize shift timing.

Why our interest in this item? We recently rebuilt a TorqueFlite for our Charger R/T, using a selection of components to enhance durability and shift quality. It really did shift great, as TorqueFlites are known to do, but unfortunately, in "D," the automatic shift speeds were way too early, particularly out of First. First gear was banging through at just 4,200 rpm. Oddly, Second gear pulled up to 5,200 rpm, which was better. We called A&A for one of their governor kits, and figured our 440 would like to pull to 6,000 rpm or more. The idea of having full automatic upshifts at these very high crank speeds was pretty exciting. A&A's guys said there was likely to be some variation on the actual shift speed with any given governor assembly, as several other variables (such as operating pressure and valvebody calibration) will affect the ultimate shift rpm. We decided on a PN 22204-58 governor assembly, rated at 5,800 rpm. There is some trial and error involved under the best of circumstances, although our case was complicated by the variation in shift rpm from 1-2 and 2-3.

Remove the small "C" clip from the center valve shaft, and then the large internal snap ring that retains the governor in the bore. The governor assembly should slide easily out of the housing bore.

Remove the small "C" clip from the center valve shaft, and then the large internal snap ring that retains the governor in the bore. The governor assembly should slide easily out of the housing bore.

With the new governor installed, our 1-2 gear change now came in hard at 5,200 rpm, up a full 1,000 from where we were. It was looking good, so we kept our foot in it, and the tranny carried Second up to 6,200-up 1,000 rpm as well. The governor raised our shift points by 1,000 rpm at both gear changes, but we still had a problematic 1,000-rpm differential between the two gear changes. We got back to A&A with the results. Calling in not as magazine guys but regular customers off the street, we were impressed with the customer service.

"Which way do you want to go?" they asked. "Up with 1-2 to match 2-3 at 6,200 rpm, or pull the 2-3 shift down to match the 1-2 shift point?" Being Mopar guys, we figure full automatic upshifts at 6,200 rpm would be simply wicked, so we opted for the first choice. We could always dial back the line pressure slightly to drop the shift rpm if it proved to be too much.

The solution from A&A was a change in the 1-2 shift-control valvespring. They sent us a selection of 1-2 shift-control valvesprings to bring the 1-2 shift up to match the 2-3 shift point. Three springs were sent, all heavier than the stocker, the tension clearly marked, and what it should do. We dropped the valvebody and popped in the spring tagged "first choice." Back on the road, it wound up in First, tached to 6,200 rpm, and banged off a solid shift. Climbing Second, the tach swept up to 6,200 rpm again, and slam, it clicked into Third. Wow, it was the best automatic TorqueFlite we ever had. The tech at A&A nailed the problem and called the valvebody spring calibration dead-nuts on. A weak 1-2 shift control spring and accompanying short-shift out of first made us dissatisfied with our fresh tranny, even though it shifted great manually. With some small parts and friendly tuning advice from A&A, we were ironically grateful for having run into the problem, ending up with a brutally cool high-speed TorqueFlite for our troubles.