As we all know, building an old truck can present all sorts of problems, but you shouldn't let selecting tires be one of them. It only takes a few minutes to learn the basics of tire manufacturing and figure out the right tires for your application, even though it's one of the easiest places to make a mistake during your truck's buildup. Some folks base their decision strictly from a budget standpoint, and end up using run-of-the-mill tires simply because they're cheaper than specialty tires, like whitewalls. We're not saying that's a bad thing, but it's still important to know what you're dealing with before you take the plunge.

Many of the trucks we feature were originally built in a time when bias-ply tires were the norm, but it's not surprising that most folks upgrade to radial technology, simply based on the smoother ride and better handling. Knowing the characteristics of each form of tire manufacturing is a big step toward narrowing down your choices, and then it basically comes down to overall size and sidewall treatment. There are many companies to choose from, with many different offerings, in terms of size, style, and construction, so do your homework before nailing down a specific tire decision.

And while the opinion of a customer sales representative is highly valued, we suggest chatting with fellow enthusiasts to get real-world feedback on particular tires. If you see a car or truck at an event and it rolls on a set of tires that peak your interest, talk to the owner and see how he likes them. Of course, chassis and suspension setup greatly affects the way a truck rides, so try talking with a few different people with similar tires and get their feedback. It's a step that can make your decision a lot easier.

Tire Development

Without question, the most common misconception in the hot rod and classic truck industry is the origin of specialty tires. Some companies use existing radial tires and apply the sidewall treatment as a secondary manufacturing process. Although it's reasonably priced and produces a good-looking tire, this method of production isn't nearly as in-depth as developing a tire from scratch. Modifying the sidewall of a tire does little for its structural stability, so other companies take the time to develop tires and manufacture them from scratch, with the sidewall treatment integrated from day one of production. Corky Coker of Coker Tire likes to call his tires a "whitewall tire with a birth certificate" because each specialty tire is born with that particular sidewall treatment built-in, just like they were in the good ole days.

At Coker Tire, it all starts with the molds, and when you consider the amount of sizes among the various brands offered, you're talking about thousands of molds.

At Coker Tire, it all starts with the molds, and when you consider the amount of sizes among the various brands offered, you're talking about thousands of molds.

Whether it's a bias-ply or a radial design, the development of a true specialty tire starts with a mold. Some molds are the original units from years past, while others are brand-new molds, built from original drawings from its original manufacturer or from scratch as a totally new design. For example, the very popular line of Firestone Deluxe Champion bias-ply tires are officially licensed by Firestone, and produced exclusively by Coker Tire. And though many bias-ply tires are produced from original molds, the use of modern materials and build techniques gives you the best of both worlds-authentic looks and modern manufacturing. Once the mold is revamped and ready to begin producing tires, the time is taken to test the finished product, using rigorous techniques to determine the particular tire's speed and load rating, as well as eliminating production flaws before the tire hits the market. It's this type of research and development that puts Coker Tire at the top of the food chain, in our opinion.

Bias-Ply

Most vehicles built prior to the 1970s came from the factory with bias-ply tires, which applies to most classic truck enthusiasts. Folks with hot rod influence tend to lean more toward the vintage styling of a bias-ply tire, because of the very popular piecrust edges and narrow tread profiles. Bias-ply tires are easily the most popular choice for traditional hot rods, and they're generally used on open-wheel hot rods of the '20s and '30s. However, they're also used on traditionally styled trucks from the '40s, '50s, and even '60s. There's no arguing the fact that radial tires perform better than bias-ply tires, but that's a sacrifice many rodders and truck enthusiasts are willing to make for the right look.

Bias-ply tires were used on all cars and trucks built before the mid '70s, so if you're restoring your classic truck to the original specs, this is the tire you want. Or if you're building a traditional hot rod, bias-ply tires are the preferred choice.

Bias-ply tires were used on all cars and trucks built before the mid '70s, so if you're restoring your classic truck to the original specs, this is the tire you want. Or if you're building a traditional hot rod, bias-ply tires are the preferred choice.

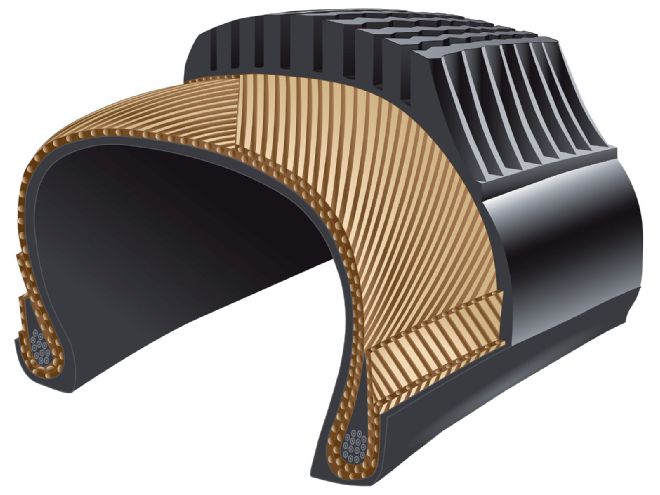

The construction of a bias-ply tire starts with nylon or polyester cord, which runs at a 45-degree angle from the tire's bead, with each layer overlapping the other in a crisscross fashion. This creates a strong and very capable tire, but the rigid structure doesn't allow the rubber to conform to the road nearly as well as a modern radial. With bias-ply tires, it is common to have a wandering feel, as the tire is likely to follow the grooves or ruts in the road. And since the ruts and grooves in the road aren't perfectly straight, that means the truck will tend to pull one way or the other if you drive on a rough road. This isn't a problem in most cases, but you can certainly tell a difference behind the wheel, as it takes a little more work to drive a vehicle with bias-ply tires. The narrow tread width can also affect the way a vehicle handles, and the tall sidewalls offer a unique feel that only a bias-ply tire can provide.

And while some folks say that a bias-ply tire isn't good for long-distance driving, tons of people do it with no trouble whatsoever. As long as you don't mind adjusting to the new handling characteristics, there's no reason you couldn't run bias-ply tires on a daily driver. It's all about preference, so figure out if you would rather have the ultimate in vintage style and suffer slightly in the handling department, or have the ultimate in handling and suffer slightly in the vintage style department.

A cutaway illustration of a bias-ply tire shows the overlapping cords, which run at a 45-degree angle from the tire's centerline. It's easy to see how this design would tend to wander on the road with its narrow tread pattern and tall sidewall.

A cutaway illustration of a bias-ply tire shows the overlapping cords, which run at a 45-degree angle from the tire's centerline. It's easy to see how this design would tend to wander on the road with its narrow tread pattern and tall sidewall.

Radial

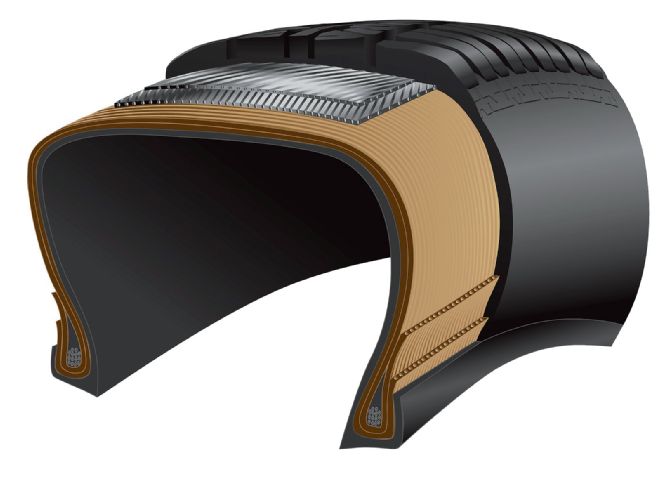

A radial tire is manufactured with efficiency in mind, and it's been proven to handle better, especially under harsh driving conditions. The tire's construction features rows of cord that run at 90 degrees from the tire's bead. With the cord traveling straight across, as opposed to diagonally, radial tires offer a more flexible design, which translates to increased traction. Radial tires also feature one or more layer of steel belting that helps strengthen the tire's structure, while retaining the overall flexibility of the tire.

Radial tires look great on the right application, but some hard-core hot rodders dislike the looks of radials on a traditionally styled car or truck. Radials have a wider footprint than bias-ply tires and have a whole different design that takes away some of the old-school flavor, but that doesn't mean they're not attractive. Radials have a smooth design with a rolled shoulder, instead of the piecrust design of bias-ply tires, allowing them to perform much better on wet and dry surfaces.

Coker Tire was the first company to produce a wide whitewall radial tire, and did so in 1994. This design was a huge hit, and since then, Coker has introduced a number of different brands and designs to meet the needs of its customers. When doing further research, we found that brands like BFGoodrich, American Classic, and Coker Classic are available from Coker Tire, and each brand has a specific tread pattern and sidewall design. Whitewall radials are Coker Tire's specialty, so offering more than one brand gives us a variety of choices when it comes time to pick up the phone and make an order.

A cutaway illustration of a radial tire displays the straight-across, bead-to-bead cord design, as well as the multiple layers of steel belting that reside beneath the tread. The smooth sidewall and rolled shoulder offer good looks for classic pickup trucks.

A cutaway illustration of a radial tire displays the straight-across, bead-to-bead cord design, as well as the multiple layers of steel belting that reside beneath the tread. The smooth sidewall and rolled shoulder offer good looks for classic pickup trucks.

Coker also offers a couple of tire models that closely resemble a bias-ply tire, but feature radial construction. One example is the Coker Classic 16-inch radial series, which has the tall and skinny looks of a bias-ply, as well as a robust shoulder, instead of the smooth, rolled shoulder like most radial offerings. Radial internals make for great driving characteristics with the vintage looks of a bias-ply tire.

The wider footprint and flexible design make radial tires handle the highway much better than their bias-ply counterparts. Coker Tire was the first company to introduce a whitewall radial, and currently produces them under several different brands and styles.

The wider footprint and flexible design make radial tires handle the highway much better than their bias-ply counterparts. Coker Tire was the first company to introduce a whitewall radial, and currently produces them under several different brands and styles.

On The Road

Once you've made the tire selection, it's all downhill from there, right? Well, there are still a few steps to be made before you can start driving. First is mounting and balancing the tires to your existing wheels-this can make or break the way a vehicle drives. Inflating the tires is a straightforward process, but there are advantages to using nitrogen inflation, as opposed to regular air. Sometimes, regular air can pass through the sidewall of a tire, and eventually lead to a brown whitewall. The larger molecules in nitrogen lessen the chances of this occurrence, and it produces less heat buildup within the tire, which keeps pressure consistent.

Balancing is a critical part of the process and most everyday tire shops use a balancer with a hub-centric mount, which means the wheel is attached to the machine by the center hole of the wheel. It doesn't take much studying to figure out that balancing a tire and wheel that is mounted by the hub doesn't correlate with real-world driving, because the wheels are mounted by the lugs when on the vehicle. For a better and more accurate reading, specialty tire shops use a lug-centric mount, so the wheel can be mounted to the machine exactly how it would be mounted to the vehicle.

One particular tire that blends bias-ply style with radial technology is the Coker Classic 16-inch radial. The sharp shoulder and narrow profile resembles the traditional bias-ply look, but the internals are all modern.

One particular tire that blends bias-ply style with radial technology is the Coker Classic 16-inch radial. The sharp shoulder and narrow profile resembles the traditional bias-ply look, but the internals are all modern.

When it comes to balancing, many original steel wheels will be out of round, or have a slight warp because of the years of abuse. This makes it tough to balance the tire and wheel assembly, so lots of folks end up buying new steel wheels. These are also available through Coker Tire, so you can buy tires and wheels together and have the folks at Coker do the mounting and balancing for you. From our vantage point, this is the right play, because it greatly simplifies the process and allows you to reap the benefits of nitrogen inflation, and skip mounting and balancing all together. From there, just bolt them on and hit the road with your brand-new tires. Whether you choose bias-ply tires or radials, or make the always tough decision of black wall or whitewall, finding the right tires for your classic truck is a key element to enjoying your time behind the wheel.