|

| www.beyondthedyno.com/blogs/eric

Got a burning question or simply need some advice with problems you've encountered while wrenching on your current/future projects? Ask our automotive guru Eric Hsu anything--literally, he's going to answer every single question, as long as it's automotive related.

Got a tech question? Send it to [email protected]

Fuel Injection Clinic

Lately, there's been numerous injector brands of different types popping out everywhere in the import market. Further research has offered the most common types, which are pintle, disc (Bosch and Lucas type), and ball. I am led to believe the pintle type, which is a common design among OEM injectors, are good for atomizing fuel for economy but are bad for performance cars whereas the disc type is the complete opposite. What type of injectors do you recommend for turbo applications versus NA cars?

-Bill Klein, via importtuner.com

| August 2013 Question IT Fuel Injectors

| August 2013 Question IT Fuel Injectors

The subject of fuel injectors, their design, spray patterns, atomization, fuel droplet size, and more, is enough to fill a book alone. I've also found that generalizing that one type of injector is best for a specific type of application would be inaccurate, since there are many other variables at play within any given engine. Factors such as engine speed, type of fuel, fuel pressure, port design, flow, velocity, piston crown, combustion chamber design, valve head size, and spark plug protrusion/location play huge roles in determining what injector might work best for an application.

Then, of course, there are the physical limitations of injector location, intake manifold runner design, and more. While it would be nice to say, "A shower injector with a 12.5-degree plume and 42 micron fuel droplet sizes located 52mm above the air horn would be optimal. . ." that might only apply to an engine with an operating range of 6,000 to 13,000 rpm. As with most things, what's optimal at 13,000 rpm isn't always optimal at or near 850 rpm, where a street car idles and spends the bulk of its time.

In general, I think it's safe to say that injectors that atomize fuel into smaller droplet sizes are ideal. The smaller the fuel droplet size, the easier for the phase change to occur from liquid to gas. The heat from the air and inside the intake port can vaporize the liquid fuel droplets into a gas easier, and this generally makes for a more consistent air and fuel mixture when the mixture enters the combustion chamber. When the air and fuel mixture is in a gaseous state, combustion can occur more evenly and predictably, which then allows an engine tuner to run more ignition advance (and possibly make more power). Keep in mind that this is only a broad generalization. Other factors, such as swirl, tumble, quench, and spark plug location, still keep the possibilities almost endless.

Another generalization is that ball and disc injectors are less susceptible to clogging than pintle-type injectors. Not all OEM injectors are pintle-type injectors. Many OEM injectors are ball and disc too. In the earlier days of fuel injection, it could probably be said that pintle-type injectors offered "better" atomization, but today's ball and disc injectors often utilize director plates, which atomize the fuel and are right on par with pintle-type injectors.

In the performance aftermarket, I think the greater concern when choosing an injector is how the injectors are matched and how the injector supplier achieves the advertised flow rate. Whether the injector is a pintle or ball and disc probably shouldn't even be a factor since both types of injectors perform similarly. Since an engine doesn't always run at 100 percent injector duty cycle, matching injectors at 100 percent is only really part of what needs to be done. For a street car, this is even more critical since the bulk of the engine's life occurs at low engine speeds putting around town or cruising on the freeway. To dynamically flow the injectors, the injector supplier needs to match the injectors not only at 100 percent, but also at different pulse widths (e.g. 2, 6, 10 milliseconds). This ensures your street car (or race car) will have matched fuel delivery to every cylinder at any pulse width. As far as I know, only the guys at Injector Dynamics dynamically flow every single injector that comes through their doors. Other injector suppliers modify their injectors differently to achieve the advertised flow. Some drill the director plate and some remove the director plate. Drilling is a very bad way to achieve increased flow since the drilling operation is not precise. Remember we're talking about fuel droplet sizes measured in microns here so any modification of the director plate should also be measured in microns. Removing the director plate entirely is another way to achieve increased flow, but then how well the injectors are dynamically flowed and matched become absolutely critical since the director plate also doubles as a flow metering device. It can also be argued that atomization is affected negatively when the director plate is removed, but personally, I don't believe a chassis dyno offers the precision and repeatability to measure the performance difference from small changes in atomization.

Another thing to look out for are injector flow matching reports from injector suppliers that show that the injectors all match with zero difference in flow between each injector. It is physically impossible to have a set of injectors match to 0 percent tolerance. Zero percent matching doesn't even occur at the Formula 1 level, so don't believe for a second that a $400 set of fuel injectors all flow identically to each other. If you buy a set of injectors, and the report shows that all the injectors flow identically, just remember my face and imagine me yelling, "bs!"

Wheel Fitment

My question concerns custom spring specifications; it's an odd question, but I hopefully won't receive an odd response. I own a '07 Infiniti M35X. I really enjoy the slammed look, and prefer going static rather than 'bagged. When I first modified the car, I couldn't find coilovers that fit my ideal slammed height (where rubbing is cool, but plowing is nerve-racking) so I opted for a custom setup instead of store-bought. I previously owned a set of KW V2's from a 350Z lying around, and I loved the way they fit on the Z. I know my M is much heavier, but I wanted to experiment. Since the M is all-wheel drive it was not a direct fit, so I modified the strut housings on the front to accommodate the KWs. Along with a little welding and hammering, they fit like a glove. I had achieved a look and ride height that no one could achieve by outright dropping in a purchased set of coilovers. Fast-forward six months and the rearend of the car is sagging! What springs could I swap out to fix the problem? I figure the same spec and same size spring with a stiffer rate might do the job. Unfortunately, KW could not help, which is understandable as I suppose they shy away from modifying their product. But they did mention that if I used a stiffer spring rate my ride height would vary greatly, so I have to find the correct "free length/stiffness" for my needs. Unfortunately, this goes way beyond my realm of tinkering with the car. Why wouldn't a stiffer spring with the same free length be perfect? Since spring rates and free length are not readily available how do I find out the perfect number? Basically save me the time, money, and effort and tell me what springs to buy that offer the same height as the KWs but last long with increased stiffness.

-Jason, via importtuner.com

First off, it's completely normal for a car to sag to some degree. This can happen from worn suspension bushings or settled springs. The older the car with more miles, the greater the chance the car will droop. Since the rear handles the bulk of the weight transfer, weight of passengers, and load of crap you put in the trunk, the rear tends to sag first. On top of this, you're operating the car at a ride height, which Nissan never intended the suspension to work at. If I remember correctly the M35's rear suspension is shared with the 350Z and G35. The KW V2's (and V3's) come with an adjustable upper spring perch for the rear. This spring perch allows you to adjust the preload, which directly affects the car's ride height. I have a G35 sedan with KW V3 coilovers myself, and to adjust the ride height, I simply adjust the rear spring's preload using the adjustable collar. You didn't mention if you already maxed out the lower adjustable perch, but if you did, then you would need the next stiffer spring with the same free length. Then you can lower the preload via the adjustable collar and adjust the car's ride height to where you want it. KW's adjustable collar for the rear of the 350Z has a pretty wide range of adjustability, so I doubt you maxed out the adjustment. I find it strange that you were able to once get the ride height you wanted, so it probably wouldn't hurt if you went to an experienced alignment shop to have them take a look at your rear suspension to make sure nothing is out of whack (e.g. bent lower arm, torn suspension bushing, and more).

Chassis Prep

My BNR32 GT-R just turned 20 this year. I have been accumulating parts over the last few years, and I'm ready to begin a major build. The car is about to be stripped to the bare chassis and I'm starting with new quarter-panels and all-new paint. Because of the age of the car, would it be beneficial to have the chassis fully stitch-welded? It will primarily be a road car, but will definitely see track use as well. I didn't want to take the path of putting a rollcage in the car (again, because it's a road car), but I wanted to maintain or even restore the rigidity to the chassis, some of which I'm sure has been lost over its 20 years of life. I won't waste your time telling you I'm "on a budget" and need "an easy fix" because that isn't my issue. I've spoken to a reputable fabricator near me, one who I know has performed similar work on similar cars. I just want to know if this is a reasonable option, or if this is something that can be achieved with a quality set of under-chassis bracing.

-Justin Attanasio, Branchville NJ

| Question IT 2013 Stitch Welding

| Question IT 2013 Stitch Welding

Stitch welding is only part of the chassis stiffness equation, and it isn't a very big part of it. While it can be beneficial, stitch welding the load bearing sections of the chassis near the subframes, suspension, and A-, B-, and C-pillars that are multiple layers of steel thick, stitch welding two layers of 1mm-thick steel isn't really doing anything for stiffness on the floorboard. I think a combination of stitch welding where it counts (shock towers to framerail, A-, B-, and C-pillars to rest of body), gussets on the chassis (framerail to firewall), and bolt-on braces would be your best bet. Optionally, expanding two-part foams can also be used to fill the framerails for added stiffness.

If you can find yourself a copy of Street Tuner Challenge Season 1 (original air date was June 2005 on Speed TV), you can see me and my then employees at XS Engineering build a BNR32 from the ground up. We poured foam in the framerails and did a complete stitch weld, but I wouldn't do that now knowing what I know now. We also did extensive gusseting of the chassis and subframes.

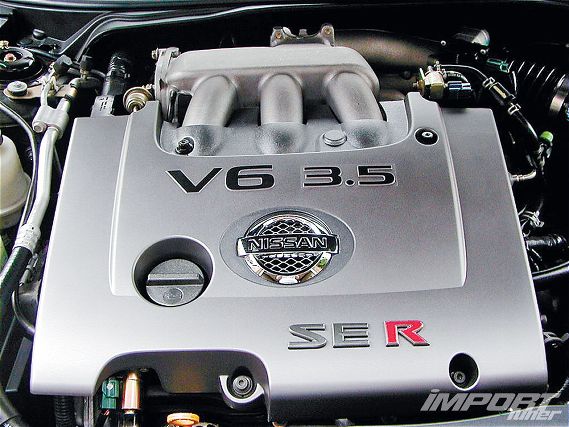

Altima SE-R

I own a '05 Altima SE-R with an automatic transmission. I would like to know if the modifications that include a Kinetix Racing intake manifold and an Injen cold air intake are worth it. After pricing the items, it looks like both parts will cost me between $1,000 and $1,200. Will these mods be worth the money or is it a waste of my time?

-Jose O., via importtuner.com

| August 2013 Question IT Altima SE R Intake Manifold

| August 2013 Question IT Altima SE R Intake Manifold

An intake manifold is probably one of the last mods you should make. This is especially true for a street car. To benefit from an intake manifold's full potential, there are quite a few other supporting modifications you'll need, such as an exhaust, ideally some headers and a Y-pipe, an intake system, and an ECU remap. After all of these basic mods, only then would I consider an intake manifold. The goal of an intake manifold is to increase airflow through the engine. It would be pretty pointless to get an intake manifold with a stock exhaust system.

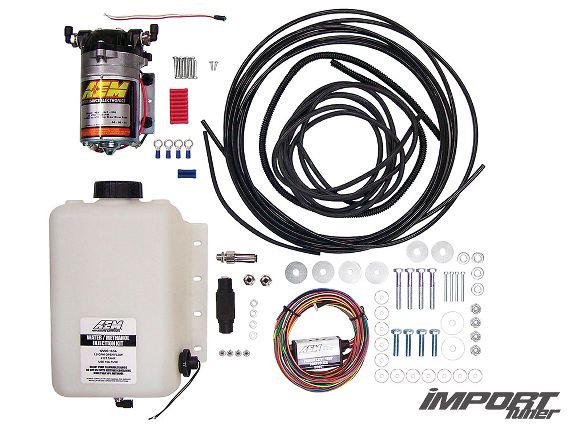

Water Methanol Injection

Greetings, Master Hsu. Instead of searching useless forums for uneducated advice, I decided to knock on your door. I recently rebuilt my Honda D16Z6 engine using 12:1 pistons, milled cylinder head, Delta 272 cam, AEM cam gear, Skunk2 intake manifold, header, intake, 2.5 exhaust, Hondata S300, and more. Basically, with all the fixings, the Civic makes 163 whp. I plan on continuing to beat my dead horse and make some more changes for time attack use, which includes highly considering a water methanol injection kit. I was wondering which kit you would recommend for my application. I know you consider it a "Band-Aid", but I would much rather hear it from your mouth.

-Brian, via importtuner.com

| August 2013 Question IT Water Methanol Injection Kit

| August 2013 Question IT Water Methanol Injection Kit

I've never used water or meth injection on a normally aspirated engine. Are you in an area with abnormally high ambient temperatures (e.g. Phoenix in July)? Methanol can definitely pull heat out the intake air, but there's only so much power that can be made that way. You'll likely have to touch up the fuel map too if using methanol, since it will effectively richen the air/fuel mixture some. If you don't have access to a high-octane fuel, then that's another reason to use water or meth injection too, since by cooling the intake air down it will lower the engine's propensity to preignite or ping. I'd actually just recommend running E85 full time over a water or meth injection kit. If your budget allows, perhaps a set of individual throttle bodies and shower injectors (with E85) might also be the way to go. Ethanol has a higher latent heat of vaporization than gasoline so it is also effective for pulling the heat out of the intake air and preventing preignition or pinging. Methanol is more effective for this, but it's a pain in the ass to have to keep filling a little reservoir in your trunk, isn't it? Plus it's highly corrosive and when burning the flames is clear making it a little dangerous too. Rock the E85. You'll be glad you did.