| Keeping With The Flow

| Keeping With The Flow

As Americans we live in a society obsessed with horsepower. The more the better, right? Is anyone really going to use a 1,000 horsepower street car? Probably not, but it sounds great saying it. The problem with generating more power is the need to take precautionary steps to ensure your engine doesn't become the next "big bang."

The Mazda RX-8, for example, is one vehicle that owners itch to modify for more power. Although an incredible driving vehicle in stock trim, the low base horsepower rating from the factory (238 horsepower at the flywheel) takes away from its sports car heritage. Compared to the 350Z and G35, each generating nearly 300 horses at the flywheel, many RX-8 owners have felt a need for a performance bump. Some owners have resorted to turbocharging or supercharging to take up some of the performance gap.

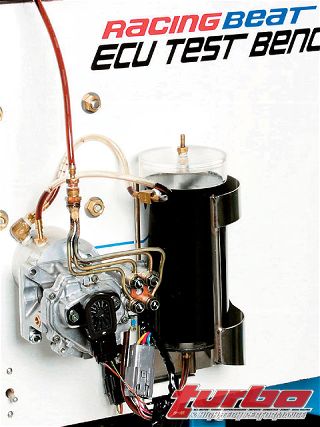

Since its inception in 1971, Racing Beat has been researching and developing performance products for the Wankel rotary engine. With over three decades of performance tuning experience, Racing Beat is one of the premier tuners for the rotary engine. Having worked closely with Mazda R&D, Racing Beat was one of the first companies to work on the Renesis rotary engine in the current-generation RX-8. Their research and development on the Renesis engine has resulted in the creation of an upgrade to the factory metering oil pump (MOP).

For those of us who are not in touch with rotary engines, the metering oil pump, found in all rotary engines, unless removed, supplies oil through fittings in the rotor housing. The injected oil aids in reducing wear and improves sealing of the apex seals against the rotor housing. The RX-8 Renesis engine MOP is controlled by the powertrain control module (PCM). The MOP flow is determined by various inputs by the PCM. Depending on rpm, load, and water temperature, the PCM can adjust the MOP to 60 different positions (steps) to determine the oil flow.

The MOP oil flow at idle is almost non-existent, but when the engine is running under a heavy load and rpm the MOP distributes a significant amount of oil into the rotor housings for additional sealing and lubrication. Although one might think since the MOP is controlled by the PCM, additional oil flow can be added with a reflash of the PCM. Unfortunately, the MOP is already running at maximum flow at the high load/high rpm of the PCM map. Racing Beat has found the only way to increase the MOP flow is by modifying the internal components of the MOP.

Racing Beat's method for modifying the stock MOP is by increasing the piston capacity of the pump. The service takes about a week and the modified pump flows up to 31 percent more oil at the "60" step.

Within the MOP there are two pistons-one small and one large. At idle and light throttle only the small piston is being used. However, under heavy load and high rpm the larger piston comes on line. Since Racing Beat only modifies the larger piston the additional 31 percent flow only becomes effective when the larger piston is engaged. This in turn means there is little or no change in oil consumption during cruising. The additional oil flow aids in lubrication and sealing of the apex seals. Racing Beat only recommends this modification for boosted engines or enthusiasts who plan to engage the vehicle under hard use (road racing, autocrossing, etc.). The MOP modification can only be performed on a good, working pump.

In Racing Beat's extensive testing of the Renesis engine, the company has found performance improvements when more oil is injected into the engine. Although it cannot be determined whether the increase in performance is from the extra lubrication of the housing or the increased sealing. Whichever way you look at it, the extra oil is a little added insurance into protecting your precious baby.