The world of automotive enthusiasm as a saying: "There's no replacement for displacement." No matter what the slogans of your favorite import shops, parts manufacturers and race teams tell you, this is 100 percent true. But forced induction can increase the amount of air and fuel your engine combusts, effectively increasing displacement as boost pressures rise. In this first part of a series, we follow our turbo-making friends at Garrett as they put us on the path to enlightenment in understanding proper turbo sizing and selection.

|

Turbo Tech 101 - Tech-Knowledge

|

Turbo Tech 101 - Tech-Knowledge

Turbocharger Fundamentals

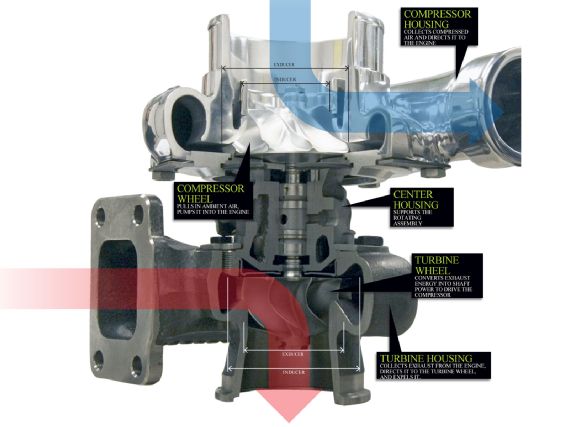

The concept of turbocharging is simple: Use the energy contained in an engine's exhaust flow to deliver increased pressures of clean air into the combustion process. As more air is delivered into each combustion event, the energy from more exhaust gas can be used to deliver increasingly more clean air into combustion for increasingly more power (a process referred to as "spooling"). Turbocharging has been used for decades to allow smaller engines to displace the air and fuel of larger ones, for improved high-elevation performance, fuel efficiency, and power. Seen here is a cutaway of a Garrett GTX3071R turbocharger.

Turbine Housing And Wheel

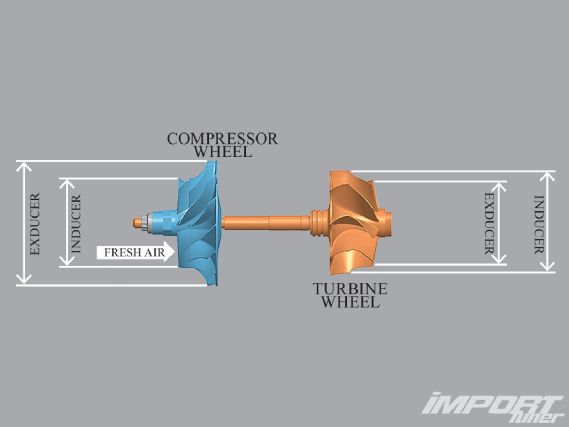

Turbocharging begins with exhaust gasses exiting an engine and entering the hot side of the turbo, collectively called the "turbine". Because they have to withstand tremendous heat, turbine housings are commonly made of thick cast iron or steel, and wheels of temperature-resistant alloys like inconel. The circumference of the turbine wheel at its widest, called the "inducer", is where exhaust gasses first begin to spin the turbine wheel. Turbine housings are shaped such to allow as much exhaust gas to collect and spin the turbine wheel as efficiently possible before exiting the turbine via the smaller part of the wheel, called the "exducer", and into the exhaust tract to be expelled from the vehicle.

|

Turbo Tech 101 - Tech-Knowledge

|

Turbo Tech 101 - Tech-Knowledge

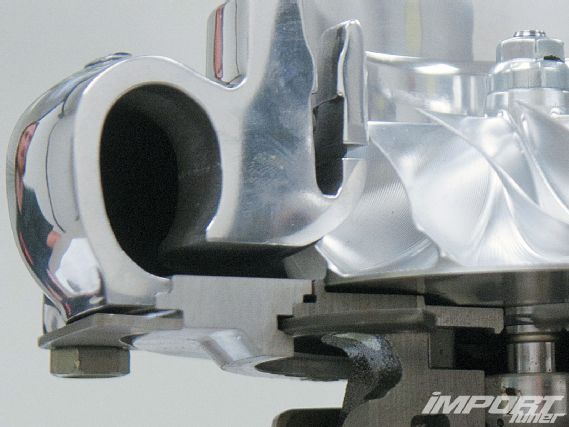

Compressor Housing And Wheel

Machined from lightweight, non-conducive materials such as aluminum, the cool side of the turbo-called the "compressor"-is where clean, ambient air is gathered and forced into combustion. Joined to the rotating turbine wheel via a common shaft, the compressor wheel at once draws air into the compressor housing where it's collected, and sends it on its way to the engine. Because ambient air is drawn into the compressor parallel to the shaft and expelled perpendicular to it (opposite of how exhaust gasses flow through a turbine), the smaller part of the compressor wheel is the "inducer" in this case, and its circumference, which propels collected clean air to the engine, acts as the exducer.

|

Turbo Tech 101 - Tech-Knowledge

|

Turbo Tech 101 - Tech-Knowledge

Center Housing/Rotating Assembly (CHRA)

Joining the two sections of the turbo is a sealed, housed common axis shaft supported by a bearing center section together called the "rotating assembly", or more commonly, the "center cartridge". Traditional turbocharger bearings are called "journal" or "sleeve" bearings and function much like the bearings found around crankshaft main and rod journals in an engine; smooth metal surfaces, keeping components apart by layers of oil to allow for low-friction rotational movement. Offered in past years as an upgrade, the ball-bearing cartridge is rapidly becoming a turbocharging mainstay for the friction-reducing benefits inherent in its design, not only to rotational movement with ball-bearings presenting smaller frictional surfaces and needing less oil to function, but also in the design of their races that simultaneously limit lateral movement, eliminating the need for friction-inducing thrust washers used with conventional journal bearings.

|

Turbo Tech 101 - Tech-Knowledge

|

Turbo Tech 101 - Tech-Knowledge

Garrett Turbo Fact

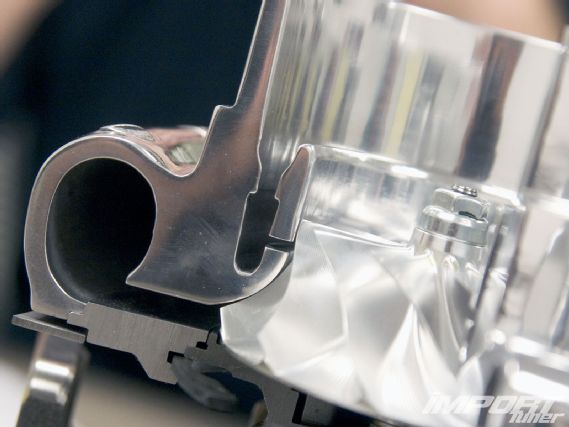

Compressor wheels are traditionally cast from steel, but newer versions, like Garrett's GTX options, are CNC machined from billet aluminum. "The GTX line is usually reserved for specialty and custom applications," says Garrett Marketing Manager Kyle Synder. "Like racing, which doesn't present a large enough demand to warrant tooling up for a cast unit." There is a side benefit of decreased weight and increased response when dealing with machining wheels from aluminum, but the real benefit is adaptability. "We can work directly with racers and the data they gather to create a wheel custom-tailored to their needs," Kyle adds.

|

Turbo Tech 101 - Tech-Knowledge

|

Turbo Tech 101 - Tech-Knowledge

Turbocharger Sizing

Most of us are somewhat familiar with gauging turbocharger size and power potential. You probably know that a T3 turbo is larger than a T28, that a GT30R is smaller than a GT42, and that a T88 is pretty damn big. You probably also know that the larger the turbo, the larger the power potential and the longer they'll take to spool up. But what exactly is in the name of our example turbo-identified as a 71mm GTX3071R-803712-1; 58-trim; 1.06 A/R-and what is it best suited for? Brush up on your high-school math. Power class is in session.

|

Turbo Tech 101 - Tech-Knowledge

|

Turbo Tech 101 - Tech-Knowledge

Wheel Sizing

It's becoming increasingly more common to hear turbos described with a simple millimeter measurement. Certain drag racing sanctions, for example, limited maximum turbo size based on this millimeter rating, most often referring to the diameter of a turbo's compressor inducer. Most of today's popular series limit maximum turbo compressor inducer size to 72mm for Sport FWD- and Hotrod-class platforms, and 67mm for True Street competition. Ruling will occasionally limit the size of compressor exducers as opposed to inducers, but for the most part, hearing a turbocharger referred to by a millimeter rating is significant only of its compressor inducer diameter.

|

Turbo Tech 101 - Tech-Knowledge

|

Turbo Tech 101 - Tech-Knowledge

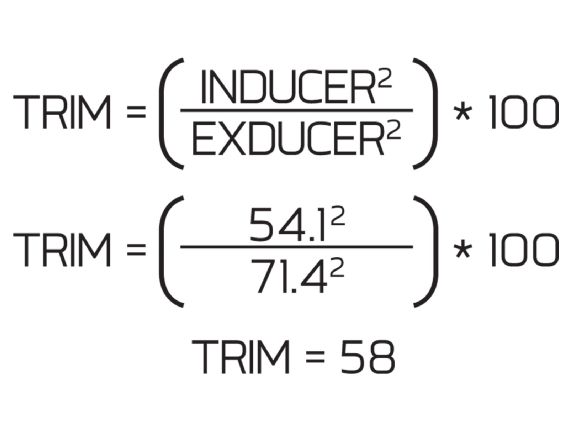

Trim

"Trim" is another commonly thrown-around term when discussing turbo sizing. Simply put, it's an expression of the relationship between the inducer and exducer diameters of turbine or (more commonly) compressor wheels, and is useful for judging how much air either one can move. It's derived by squaring the diameter of the wheel's inducer, dividing that value by the squared diameter of the exducer, multiplying by 100, and rounding up.

|

Turbo Tech 101 - Tech-Knowledge

|

Turbo Tech 101 - Tech-Knowledge

With all other factors held constant, a wheel with a higher trim rating will flow more than one rated smaller. Applying the formula below, we see that the compressor wheel of our GTX3071R example weighs in at 58 trim.

Frame

Possibly more commonly used as an identifier of turbo size is the classification of its frame. "Turbos and CHRAs are grouped in size ranges, called frames, according to the diameter of their turbine inducers," explains Kyle. "Garrett previously classified frames with just a 'T' designation-T25, T28, T3, T4-but we've moved away from that system to the GT designation you see today." In the case of our GTX3071R turbo, the additional letter denotes its billet aluminum GTX compressor wheel. Turbos of the same frame designation have turbine housings from similar castings, but there can be significant differences in their machining, which compressors they're paired with, and which wheels they house. Garrett currently offers six different off-the-shelf GT30 turbos, each available with different A/R and flange options.

Nomenclature And Cataloging

Now that we've figured out the trim and A/R sizing, frame, and the compressor inducer diameter of our GTX3071R turbo, what else is in its name? After that we see the letter "R" which tells us the turbo has a ball-bearing center. Any additional letter-like the "S" in the GT2860RS Disco Potato turbo-stands for "special." But what about the rest of the numbers? "Cataloging," says Kyle. "Plain and simple."

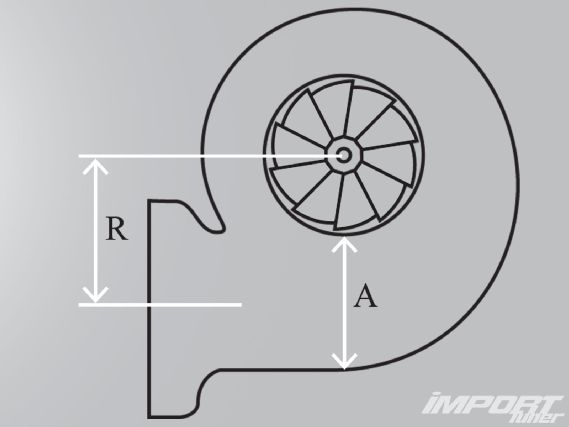

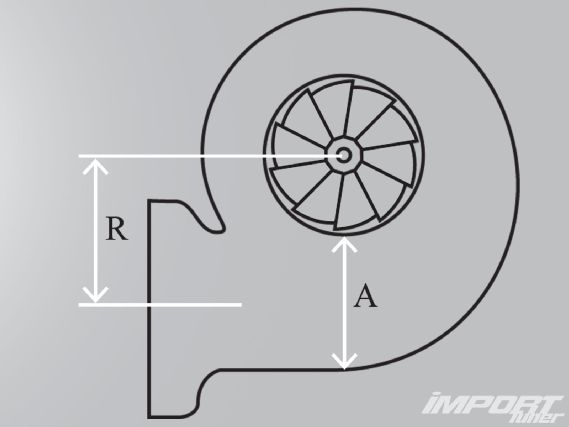

A/R

Standing for area/radius ratio, A/R is most commonly used to expresses the flow capacity of a turbine housing, though it can be applied to compressor housings, too. It's the relationship between the distance from a turbo's centerline to the centroid of an area in the housing opposed at 90 degrees both to the centerline and an imaginary line perpendicular to the centerline, and the corresponding area of the turbine inlet or compressor outlet surrounding that centroid. In the illustration below, "A" represents area around the centroid, and "R" represents the distance from turbo centerline to the centroid.

|

Turbo Tech 101 - Tech-Knowledge

|

Turbo Tech 101 - Tech-Knowledge

The important thing to remember about A/R is that the larger the number, the more the housing will flow. The turbine housing of our GTX3071R example is available in three different A/Rs from Garrett: 1.06, 0.82, and 0.63. The 0.63 option will effectively "funnel" exhaust gasses tighter and faster through the turbine wheel, allowing its compressor wheel to spin faster, sooner, to generate more low-end power-great for smaller-displacement engines or low-rpm performance when less exhaust gas is flowing through the turbine. Conversely, the 1.06 option offers more area inside the turbine housing for exhaust gasses to collect, meaning better performance at higher rpm, on a larger displacement engine, or when using nitrous oxide in conjunction with turbocharging. Compressor performance is generally insensitive to A/R, since the vast majority of compressor housings are matched to compressor wheel trim.

Garrett Turbo Fact

The thickness of production turbine housings is an industry-regulated standard; in the event that a turbine wheel explodes (which rarely happens), it has to be able to contain any part that may be ejected. "In racing instances, we can produce thinner housings for reduced weight," explains Kyle Snyder, "but these parts have to be cast, so the cost is high. Only the big leagues use these."

|

Turbo Tech 101 - Tech-Knowledge

|

Turbo Tech 101 - Tech-Knowledge

Make sure to continue reading as we decode compressor mapping, and explore turbocharger/displacement/power matching, going as far as to maximize power and torque dependent on gearing. Hell, we might even learn something we thought we knew already!