Technical Honda engines just seem to work. All the time. We expect them to go well beyond the six-digit mile marker. To be sure, the threshold at which a Honda is considered "high-mileage" is above that of most other makes. Follow the recommended maintenance schedules and most any Honda engine will eclipse 300,000 miles relatively easily. But Honda isn't free of imperfections. Such has been revealed most recently among its K-series engines.

|

Honda K Series Tensioner - The Truth Behind The Failure

|

Honda K Series Tensioner - The Truth Behind The Failure

There's no doubt that Honda's K-series lineup is the company's most sophisticated four-cylinder to date, but it has a weak link-its timing chain tensioner. First, though, a little background information.

Timing Origins Honda's engineers have long been fans of belt-driven valvetrain assemblies. Accords, Civics, Integras, Preludes, NSXs, you name it they've all been belt-driven. It's only recently that the company's switched to chains in order to link its engines' camshafts to their crankshafts and control valve timing. Perhaps that's because timing belts simply work, and when replaced periodically, are as reliable as any chain. But timing belts are prone to wear-just as much so on engines that rarely see the light of day as they are on daily driven ones, which is why Honda's timing belt replacement intervals are based on both time and mileage. Imagine for a moment the stress that's placed on an unused engine's belt as it's continually stretched in one specific region while the rest of the engine takes a breather. Engines that are regularly cycled condition their belts evenly, which arguably adds life to them. The situation isn't much different from the power window regulator that dies first on the window you use least.

Enter The Timing Chain But consumers don't pay attention to things like recommended maintenance schedules. To reduce maintenance further, Honda introduced its chain-driven valvetrain on its S2000 and then later on its K-series engines for the 2002 model year. The assembly isn't much different from a belt-driven one, though, save for the whole chain thing. There are still a couple of cam gears, still a crankshaft and crankshaft pulley, and still a tensioner that keeps the chain from falling off, preventing important metal parts from mashing up against one another.

Timing chain tensioners are simple but important. Take Honda's K-series, for example. As the engine rotates clockwise, the crankshaft keeps the intake side of the chain tight simply because of the direction the chain's being pulled, but it's the tensioner's job to do so for the exhaust side. Without it, the cams would start spinning but ultimately just sit there doing nothing as the chain slips and bounces around. Spin far enough out of sync and watch expensive pieces like valves and pistons start to touch one another. Ouch.

How They Work K-series tensioners aren't terribly complex and, simply put, do little more than push a small piston back and forth against the engine's timing chain guide, keeping the chain tight. They do so hydraulically-not unlike older H22A tensioners-which means K-series tensioners operate by way of oil pressure, but they also incorporate a small, internal spring for mechanical purposes. At low engine speeds, when oil pressure is low, the tensioner's internal spring mechanically moves its piston toward the timing chain guide, reducing chain slack on the chain's exhaust side. As engine speed and oil pressure rise, the spring relaxes and oil pressurizes the tensioner's chamber, hydraulically pushing its piston toward the chain's guide. A check valve ensures the oil doesn't escape prematurely and a release valve lets it out when the tensioner's done, well, tensioning things. Additionally, a ratcheting mechanism and teeth built into the piston ensure that it doesn't retract too far back into its housing and loosen up the chain. Sounds like Honda has it all figured out.

The Problem Unfortunately, Honda's internal tensioner spring doesn't always work as you'd expect, and excess tensioner piston travel (more than 0.25-inch) and timing chain slack when oil pressure is low is common-especially while cranking and at low engine speeds when the spring is doing all the work. The results can cause the piston teeth to slam against the tensioner's ratchet, ultimately grinding their tips off, rendering them ineffective. You see, by design, K-series exhaust valves close rapidly. Each time they slam shut, the chain builds slack. And each time they slam shut, the tensioner's piston bashes against its ratcheting mechanism. Aftermarket cams with aggressive profiles and stiffer valve springs only pronounce this. It should be noted that although dealership technicians have reported worn tensioner pistons on otherwise stock engines, it's more likely once camshafts and springs have been swapped. Steeper exhaust closing ramps and stiffer valve springs that close the valves even quicker are to blame. Of course, none of this is good since the ratchet and piston teeth are the only things that prevent the piston from being pushed in too far. All of this can lead to a loose chain, a failed safety mechanism, and engine damage, even on unmodified engines. Worst of all, you'll never know any of this is happening until it's too late since you can't readily monitor the tensioner and, even if you could, all of this happens way to quickly.

The Solution The simplest and least expensive fix is to add a click to the tensioner by manually moving its piston one tooth closer toward the chain. This method reduces how far the piston can retract back into the tensioner housing, but it doesn't solve the overall problem or make the ratchet and piston teeth any stronger. Adding a click is easy but it isn't a permanent solution.

Stiffer tensioner springs have also been experimented with by various companies, but this doesn't address the weak ratchet and piston teeth issue. What it does do is resist excessive piston movement and bashing at start-up and during low oil pressure situations, though, which is, after all, the reason the ratchet and piston teeth get damaged to begin with.

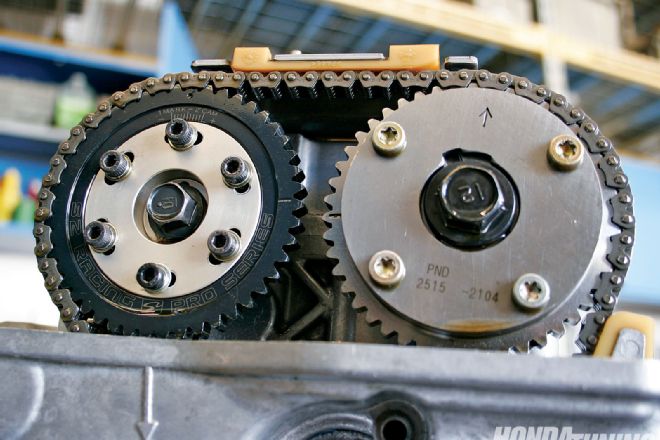

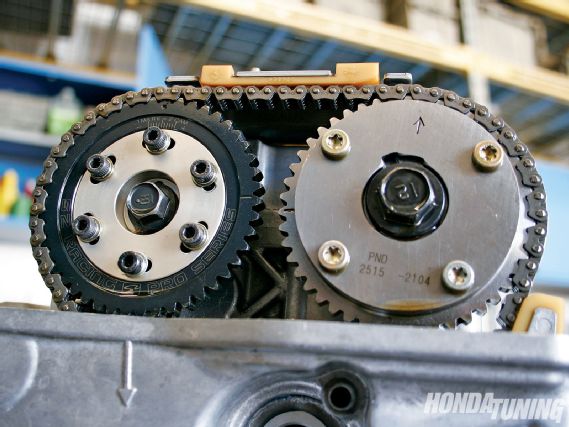

Both Hybrid Racing and Skunk2 offer more comprehensive solutions. Both companies' tensioners are based off of Honda's design but are machined from scratch. Both use stiffer internal springs that prevent the exhaust camshaft from slamming shut at low engine speeds by eliminating chain slack, even under low oil pressure conditions where the factory spring is typically compromised. Both Hybrid Racing and Skunk2 also address the tensioner's piston and safety mechanism. Hybrid Racing's Timing Chain Tensioner's piston features teeth on both sides for even load distribution, while Skunk2's Pro Series Timing Chain Tensioner features taller teeth that, even when filed down or damaged, are deep enough to engage its ratchet. Skunk2's tensioner's piston is also 1.5mm larger than the OEM one and features a larger ratcheting mechanism. Both tensioners also feature provisions to fit tightly against the timing chain guide to ensure against rotational movement, which can exert uneven load against the ratcheting teeth. Even the factory-designed oil passages and check valves are retained, which means both tensioners remain lubricated and pressurized just as Honda intended.

There's no doubt that Honda's K-series lineup is the company's most sophisticated four-cylinder to date. Now consider its weak link resolved.