Having significantly improved our '06 Infiniti G35 Coupe's handling, braking and power delivery, the factory viscous limited slip differential's torque transferring ability has been increasingly exposed as a weak point during track testing. For the street, this type of differential is unobtrusive and relatively effective, but at the racetrack it quickly overheats and loses its ability to transfer torque to the wheel with the most available traction. Simply put, the factory VLSD isn't up to the task of converting available horsepower into forward motion when repeatedly dropping the hammer while exiting corner after corner around a racing circuit.

|

Putting The Power Down - Project 2006 Infiniti G35

|

Putting The Power Down - Project 2006 Infiniti G35

To address this weakness and allow our normally aspirated RevUp VQ35 to make the most of its 260 whp, we contacted our friend Yasu Fukui at Performance Partners Inc. PPi is an authorized U.S. dealer for ATS (Active Traction Service), a highly reputable Japanese manufacturer of clutch-type limited slip differentials, clutches, final drives and transmission gearsets. Because our G35 is a daily driver, we were wary of using a clutch-type LSD because they tend to be quite noisy, especially when making slow, tight turns. The chattering noise and jerking motion that results from the aggressive cam angle and binding of the clutch plates isn't an issue for a race car given the highly responsive torque transferring ability of this type of differential, but for a street machine it can be more than a little embarrassing pulling into a parking spot with the rear end of the car chattering and hopping around.

To address the noise and smoothness issues of a clutch-type differential, ATS has developed what it calls the Super Silent LSD. This is still a metal clutch-type differential and therefore retains much of the inherent goodness of this approach to torque transfer, but by reducing the cam angle and redesigning the clutch pack for a quieter, smoother and more gradual engagement, the streetability of ATS's new Super Silent LSD is arguably on par with far less aggressive types of LSDs, including viscous and gear-type (torsen or helical). For a more detailed discussion of how ATS developed the Super Silent LSD, visit http://www.ppi-ats.com/LSD/Silent_LSD_tech.html.

To make the installation a little easier, we picked up a used pumpkin from a wrecker so that we could build it with the Super Silent LSD while still driving the G35 to/from Auto Analyser Racing, where Andrew handled the install for us. After draining the diff fluid and removing the cover, Andrew measured total preload, ring gear to drive pinion backlash and ring gear runout and then measured these again after installing the ATS LSD so that we could ensure the new diff was installed in the same position as the OE unit and within the factory tolerances and specifications. After carefully marking all fasteners, bearing caps and shims, the roller bearings were pressed off the factory diff and onto the ATS diff and the ring gear was then transferred over and torqued to spec using an SPX OTC Angle Meter. After bolting the ATS LSD into place within the diff housing, a Nismo finned differential cover-supplied by www.mynismo.com-was then sealed and bolted up before filling the freshly built pumpkin with break-in fluid. The Nismo cover not only increases fluid capacity, the fins provide increased surface area for greater cooling, both features that should allow the ATS LSD to function optimally while prolonging the life of the diff fluid and the differential itself. What we didn't expect was the clearance problem the Nismo diff cover had with the Rear Active Steering assembly on our '06 Sports Package coupe, but with some careful application of a die grinder enough material was removed from the cooling fins to allow our freshly assembled pumpkin to bolt into place.

|

The ATS Super Silent LSD bolted and shimmed into place in our pumpkin.

|

The ATS Super Silent LSD bolted and shimmed into place in our pumpkin.

After breaking in the LSD by doing figure-eights in a parking lot for about 20 minutes, we swapped in some fresh Motul 90PA diff fluid and headed to the racetrack, where we've done all of our G35 testing. Our previous best lap time, with the factory VLSD in place, was 1 minute, 23.8 seconds around this 11-turn, 3km circuit. With the ATS Super Silent LSD in place, that time dropped to 1:22.9, almost a full second quicker. As you can see from the speed comparison between the ATS-equipped lap time (page 92, blue line) and the factory VLSD lap time (red line), maximum speed on each straightaway (as represented by the peaks across the graph) was significantly higher because of the ATS clutch-type LSD's ability to put the power to the ground more effectively. This was very noticeable from the driver seat, where early application of the throttle generated some useful rotation of the chassis and some easily controlled power slides. The factory VLSD was never able to transfer enough power to the tire with the most traction such that throttle-on rotation or oversteer was achievable in anything but the slowest and tightest corners, but with the ATS LSD power-on oversteer can now be induced even in higher-speed sweepers and full-on Formula D drifts are a piece of cake in the tighter turns.

|

Putting The Power Down - Project 2006 Infiniti G35

|

Putting The Power Down - Project 2006 Infiniti G35

OK, so ATS's metal clutch-type LSD is vastly superior to the factory viscous LSD in a high-performance environment like our test track, but what's it like on the street? Well, to be perfectly honest, there's still some chatter and a bit of binding when the diff fluid hasn't fully warmed up, but once it's up to temp this LSD lives up to its Super Silent name. Upon the advice of Yasu, we're going to try adding some Nismo friction modifier in an effort to eliminate the fairly minor chatter issue we've experienced during warm-up, but even if it's never 100 percent silent the on-track performance gains are so significant that I'm personally more than happy to live with a little noise during the first few corners of the day. Once we've tested the friction modifier and put some more miles on this differential, we'll report back on how silent it really is.

|

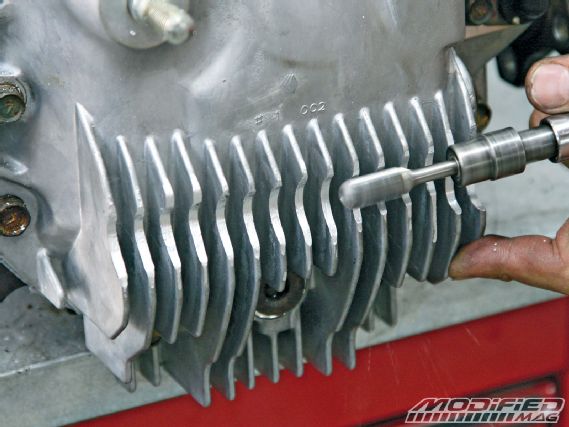

A bit of die grinder action was required so that the Nismo finned diff cover would clear the G35's RAS system.

|

A bit of die grinder action was required so that the Nismo finned diff cover would clear the G35's RAS system.

Sorting The Details

NISMO clutch line: If you take your 350Z or G35 to the track, upgrading to a Nismo clutch line is a very good idea because this braided steel heat-wrapped line offers some much needed thermal protection from the exhaust manifold on the driver side. Without it, you may find the clutch fluid boils after a few hard laps around the racetrack, just like we've had happen on Project G35 before installing this part from www.mynismo.com.

|

Putting The Power Down - Project 2006 Infiniti G35

|

Putting The Power Down - Project 2006 Infiniti G35

NISMO 50mm long hub bolts: Nissan hub bolts are notoriously soft and prone to sheering off if you over-tighten the lug nuts. To prevent this and to give us the ability to run wheel spacers on Project G35, we installed a full set of Nismo 50mm long hub bolts provided by www.mynismo.com.

Project Kics R40 lug nuts: To accommodate the longer Nismo hub bolts, we needed a set of open-ended lug nuts. A set of Project Kics R40 locking nuts were ordered from Mackin Industries. These lightweight masterpieces feature a two-piece design where the top of the lug spins freely from the tapered centering ring. This ensures a precise hold and minimizes scratches to the lug seat on your wheels.

|

Putting The Power Down - Project 2006 Infiniti G35

|

Putting The Power Down - Project 2006 Infiniti G35