Back in the day, most aftermarket and factory turbocharger systems featured simple log-style exhaust manifolds. But just like on normally aspirated engines, where exhaust manifold design has become recognized as a critical element to maximizing horsepower and torque output, there has been increasing attention paid to turbocharger and turbo manifold design. Divided or "twin-scroll" turbos and manifolds have emerged as the preferred design of many of the top tuners and even OEMs, showing up on high-performance models like the Mitsubishi EVO, Pontiac Solstice GXP and JDM Impreza STI. But what exactly are the differences between single-scroll (or constant pressure) turbo systems and twin-scroll (or two-pulse) turbo systems and how do these design differences impact overall engine performance?

|

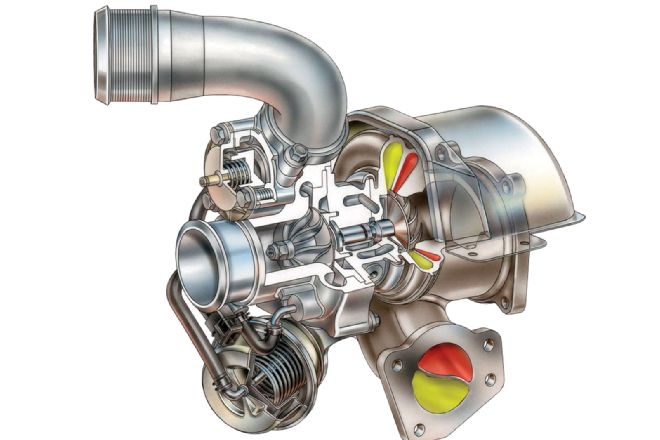

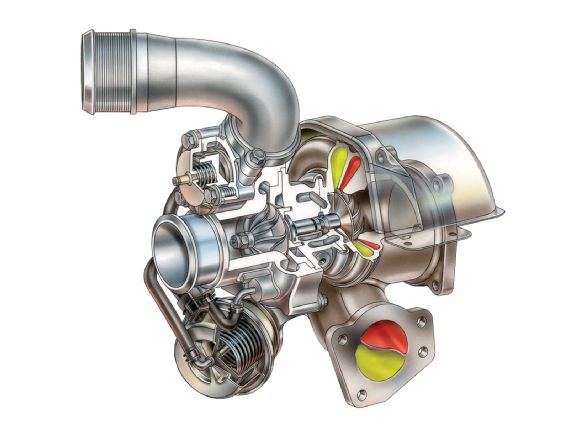

Here you can see how a divided or twin-scroll turbocharger has two separate exhaust gas entry paths into and through the turbine, maintaining the improved scavenging effect and exhaust gas flow achieved by pairing complementary exhaust primaries on the header.

|

Here you can see how a divided or twin-scroll turbocharger has two separate exhaust gas entry paths into and through the turbine, maintaining the improved scavenging effect and exhaust gas flow achieved by pairing complementary exhaust primaries on the header.

Single-scroll systems have been in use for a long time, and for good reason. These systems are generally compact, inexpensive and extremely durable under the high heat they're exposed to. So from a simplicity of design, packaging and reliability standpoint, a single-scroll, constant-pressure turbo system is quite appealing-especially to the OEMs that must consider more than just power production. Although log-style or simple unequal-length turbo manifolds used by the OEMs can be tweaked for improved performance or replaced by a more sophisticated equal-length aftermarket manifold, this doesn't change the fact that there's a single exhaust gas inlet to the turbo's "hot side" turbine (which powers the "cold side" compressor, force feeding a denser and therefore more oxygen-rich air charge into the combustion chamber from the intake side). Because of this design limitation, single-scroll systems are not particularly efficient at low engine speeds or high loads. This decreased turbine efficiency contributes to turbo lag, something we've all probably experienced while driving a stock turbocharged vehicle.

|

A Look At Twin Scroll Turbo System Design - Divide And Conquer?

|

A Look At Twin Scroll Turbo System Design - Divide And Conquer?

One of the biggest limitations of most factory single-scroll turbo system is the restrictive nature of its log or compact unequal-length exhaust manifold. Keep in mind, the purpose of this manifold isn't just to channel exhaust gases to the turbocharger's turbine wheel; the manifold must be designed to allow exhaust gases to exit the combustion chamber of each cylinder quickly and efficiently. Also keep in mind that these exhaust gases do not flow in a smooth stream because the gas exits each cylinder based on the engine's firing sequence, resulting in distinct exhaust gas pulses. Next time you fire up your car, place your hand lightly over the exhaust tip (before it gets hot!) and you will feel these pulses. With a log-style or compact OE-style, unequal-length runner exhaust manifold like you'll find on SR20DET or USDM STI engines, the pulse from one cylinder can interfere with subsequent exhaust gas pulses as they enter the manifold from the other cylinders, inhibiting scavenging (where the high-pressure pulse draws the lower pressure gases behind it out of the combustion chamber with it) and increasing reversion (where exhaust gas flow is disturbed so much that its direction of travel reverses and pollutes the combustion chambers with hot exhaust gases). The trapped and wasted kinetic exhaust gas energy from poor scavenging and too much reversion also means higher combustion and exhaust gas temperatures, necessitating less aggressive ignition timing and reduced valve overlap as well as richer air/fuel mixtures (and higher NOx emissions).

|

The advantages of a twin-scroll turbo system are not lost on the OEMs, many of which are starting to use this setup on their high-performance models, like this new MINI Cooper S engine.

|

The advantages of a twin-scroll turbo system are not lost on the OEMs, many of which are starting to use this setup on their high-performance models, like this new MINI Cooper S engine.

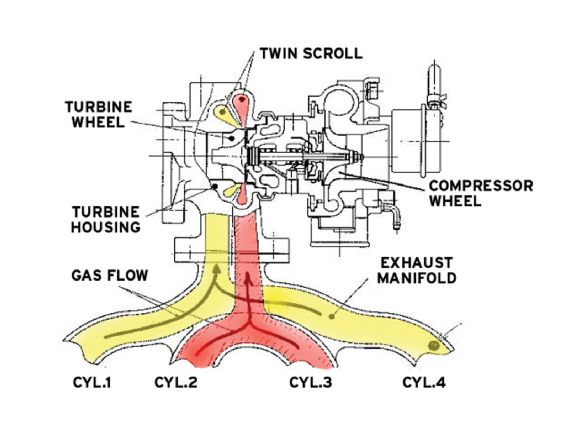

Twin-scroll turbo system design addresses many of the shortcomings of single-scroll turbo systems by separating those cylinders whose exhaust gas pulses interfere with each other. Similar in concept to pairing cylinders on race headers for normally aspirated engines, twin-scroll design pairs cylinders to one side of the turbine inlet such that the kinetic energy from the exhaust gases is recovered more efficiently by the turbine. For example, if a four-cylinder engine's firing sequence is 1-3-4-2, cylinder 1 is ending its expansion stroke and opening its exhaust valves while cylinder 2 still has its exhaust valves open (while in its overlap period, where both the intake and exhaust valves are partially open at the same time). In a single-scroll or undivided manifold, the exhaust gas pressure pulse from cylinder 1 is therefore going to interfere with cylinder 2's ability to expel its exhaust gases, rather than delivering it undisturbed to the turbo's turbine the way a twin-scroll system allows.

|

Two finely crafted, equal-length manifolds from Full-Race, where the divided flange fed by paired primaries clearly differentiates the twin-scroll design (left) from the single-scroll design (right).

|

Two finely crafted, equal-length manifolds from Full-Race, where the divided flange fed by paired primaries clearly differentiates the twin-scroll design (left) from the single-scroll design (right).

The result of the superior scavenging effect from a twin-scroll design is better pressure distribution in the exhaust ports and more efficient delivery of exhaust gas energy to the turbocharger's turbine. This in turn allows greater valve overlap, resulting in an improved quality and quantity of the air charge entering each cylinder. In fact, with more valve overlap, the scavenging effect of the exhaust flow can literally draw more air in on the intake side while drawing out the last of the low-pressure exhaust gases, helping pack each cylinder with a denser and purer air charge. And as we all know, a denser and purer air charge means stronger combustion and more power, and more power is good!

But the benefits of twin-scroll design don't end there. With its greater volumetric efficiency and stronger scavenging effect, higher ignition delay can be used, which helps keep peak temperature in the cylinders down. Since cooler cylinder temperatures and lower exhaust gas temperatures allows for a leaner air/fuel ratio, twin-scroll turbo design has been shown to increase turbine efficiency by 7-8 percent and result in fuel efficiency improvements as high as 5 percent.

Combine these benefits with a well-engineered tubular equal-length manifold and the design strengths of a twin-scroll approach can pay even bigger dividends. "Equal length" simply refers to the length of the primary exhaust manifold tubes or runners that the cylinder head exhaust ports breath out into, which should ideally be of equal length before merging at a narrow angle at the collector so that the gases flow smoothly together into the turbine inlet. This helps maintain exhaust gas pulse energy, resulting in better boost response and overall higher turbo efficiency.

Designing a high-performance twin-scroll tubular manifold like those available from top tuners like Full-Race is no simple task. Fitting equal-length primaries into the tight confines of a turbocharged car's engine bay while maintaining proper radius bends and strong exhaust gas flow characteristics is a serious design challenge. Determining the best length and diameter of the primaries and angle of the merge collector also requires a lot of R&D, as does choosing the best wall thickness and material for the tubing itself. That's where Full-Race's team of highly educated mechanical engineers and years of constant refinement of their designs comes into play. According to Geoff at Full-Race, "Because of the increased turbine efficiency found in twin-scroll systems, twin-scroll manifolds can often use a smaller runner than a single-scroll design. However, due to the complex shape of the runners and the requirement for a second wastegate and dumptube (one for each side of the divided turbine) there's more mass and more parts which adds expense and complexity. Plus, twin-scroll turbos are physically larger than their single-scroll equivalents, so it's more difficult to make them fit our cramped engine bays." Overcoming these challenges means developing extremely robust manifolds that make smart use of the available space, something Full-Race does with the help of computer programs like SolidWorks and other proprietary processes.

|

A Look At Twin Scroll Turbo System Design - Divide And Conquer?

|

A Look At Twin Scroll Turbo System Design - Divide And Conquer?

All this hard work does translate to serious performance gains in the power-delivery department, particularly at spool-up and peak torque where sophisticated tubular twin-scroll manifolds properly matched to a twin-scroll turbo deliver superior airflow to single-scroll or OE twin-scroll designs. According to Geoff, "Our twin-scroll turbo kits have a higher average cylinder pressure and turbine efficiency, while single-scroll systems tend to have a higher peak cylinder pressure and exhaust backpressure. We have found the twin-scroll systems have higher backpressure at low rpm (which is good for turbo spool-up) and lower backpressure at high rpm (which is good for top-end performance). On the other hand, single-scroll systems have lower backpressure at low rpm (bad for spool-up) and higher backpressure at high rpm (which hurts top-end performance)." In order to realize the full benefit of a top-shelf twin-scroll system like one of Full-Race's, the manifold design and A/R ratio of the turbo must be spot-on, so it's best to get the help of a professional when choosing a turbo for this type of system.

It's certainly possible to generate huge power and great high-rpm performance with a single-scroll turbo system. There are plenty of examples of very high-horsepower, single-scroll turbocharged engines out there, but with single-scroll systems spool-up and response are much slower than with a twin-scroll design, yet twin-scroll systems still provide excellent top end performance. Although switching from single-scroll to twin-scroll can be expensive, for hard-core boost junkies who want much faster throttle response without giving up any top end, there is no better solution. With the added benefits of higher turbine efficiency, lower cylinder temps and EGTs which allow more aggressive timing and fuel mapping, and the freedom to run more overlap,twin-scroll turbo system design is really a perfect match for the high specific output engines featured in many of our favorite sport compact machines.

Send your feedback to [email protected]