Part 4

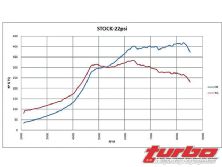

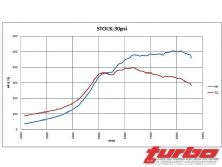

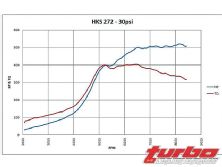

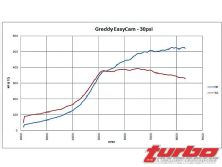

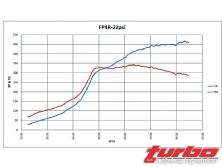

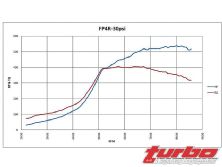

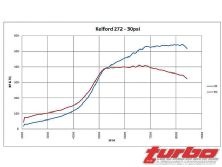

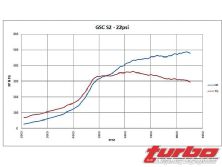

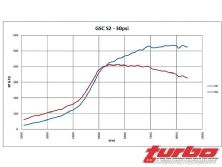

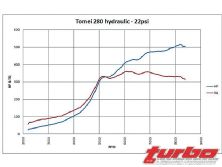

It's time to wrap up my big round of cam testing. Finally,my motor will be able to rest after the numerous dynobeatings and cam swaps. Although it was an exhaust-ing test, it really produced some great results. It's prettyamazing to look at the difference in power from the stockcamshafts to one of the aggressive drag-oriented camshafts. The Tomei 280 hydraulic lifter cams put down over 50-peak wheel horsepower more than the stock pieces, and an amazing 65 whp at redline (8,500 rpm). That could give a boost of 6 to 8 mph through the traps at the dragstrip. For well under $1,000 you can pick up 70-crank horsepower; it's like having a 75-shot of nitrous that never runs out.

So what did we learn? By studying the lift profiles of all the camshafts and comparing them to the dyno data, I drew a few conclusions. The big power cams had a couple things in common: poor low-rpm performance and idle. They also close the intake later to allow for higher cylinder pressure at high rpm, which hurts the spool-up and low-rpm running. Another interesting thing to notice is early exhaust valve opening. Compared to a naturally aspirated engine, a turbocharged engine keeps a higher average cylinder pressure longer on the piston during the combustion cycle, so opening the exhaust valve early bleeds the pressure and can kill the power stroke. An exhaust note will actually be louder and have a more pronounced pop when the exhaust valve opens earlier. At higher power levels the earlier exhaust valve opening gets rid of more exhaust gases and reduces pumping losses. So the typical trade-offs of early exhaust opening and late intake valve closing make big power and hurt the bottom end grunt. Normally, correct valve overlap works well in a naturally aspirated application but from what I've seen here, it's not as critical in a turbo application. More overlap didn't correlate to an increase in power in most cases, but it did hurt idle quality. The real behind-the-scenes secret is actually something few people outside cam design circles talk about.

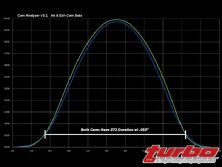

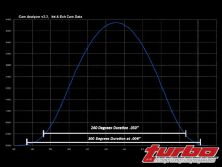

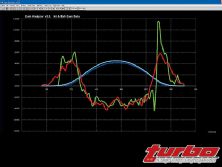

The cams that performed well had good opening and closing ramps on the valves, meaning they properly started to open and close the valve. Analyzing the lift curves in depth really shows the inner workings of the cam lobes. The lift curve shows valve position versus crank degrees, or how far it's open/closed compared to rotation of the crank. The first derivative of position is velocity, which is simply how quickly your position is changing. If it isn't changing, then guess what? Zero velocity. If you travel 20 miles in one hour, obviously you're going 20 mph. A valve isn't moving at a constant speed, so it's constantly speeding up and slowing down. The Performance Trends Cam Analyzer software does the math for you and you can plot velocity on the same graph as position. Now you can see how fast the valve is moving at each position of the crank. It's clear now by looking at the graph that velocity is constantly changing. From here we can calculate acceleration, which is the derivative of velocity, or how velocity is changing. If you're traveling at 60 mph and floor it, you're going to accelerate. Let's say you're gaining 2 mph per second, so every second you're adding 2 mph to your speed. Why am I going over this? Here comes the important part. A good cam lobe design keeps peak acceleration down. This is critical as acceleration imparts loads and stresses to valvetrain parts. Imagine getting rear-ended by a big semitruck going 60 mph, you're going to have huge acceleration, but the stress is also huge. Now imagine being rear-ended by a 10-ton marshmallow going 60 mph, strange perhaps, but you're acceleration will be much lower and much less stressful. Plotting acceleration on the lift versus crank angle graph, we can see the peak positive and negative accelerations as the valve is opening and closing.

As you can see from the acceleration graph on the right, one cam has much higher acceleration forces than the other. Guess which cam will be easier on the valvetrain?

This parameter is very important because if the valve is closed too fast, premature valve seat and valve wear will occur. We can actually go further and derive acceleration into jerk, which is the rate of change of acceleration. The car in my previous example that was accelerating at 2 mph per second isn't going to keep accelerating like that, it will eventually start to slow its acceleration as aerodynamic drag takes its toll. Jerk is also critical in calculating valvetrain loads and harmonics. I'll stop there as it can go even further than that. Cam lobe design is complex and many things need to be taken into consideration. Ideally, we want the valve open for as long as possible but to do so we need to open and close the valve quickly. It's a big game where the designer optimizes the lift profile to maximize gains while ensuring the valvetrain holds together. If the engine is designed for only drag racing, we can push the limit further as the operating time is much less than a road race engine for example. A purpose-built drag race engine might only see 30 trips down the dragstrip before a tear down, while an endurance engine might have to last the 24 hours of Daytona.

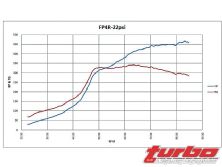

It's difficult to compare all of these camshafts and pick a winner. If I were drag racing the winner would be either Tomei 280's or the Crane's. If my car took me to work everyday and I did a few track days throughout the year I'd go with something more mild like the Forced Performance 4R's or the Kelford 272's. The very mild cams like the GReddy Easy Cams and HKS 272 would be more suited to the stock Evo turbo rather than the GT35R that I used.

AEM

www.aempower.com

AMS Performance

www.amsperformance.com

BC Brian Crower

www.briancrower.com

Crane Cams

www.cranecams.com

Forced Performance

www.forcedperformance.com

GReddy

www.greddy.com

GSC Power-Division

www.power-division.com

HKS USA

www.hksusa.com

Kelford Cams

www.kelford.co.nz