| Supercharged - Garage.Tech

| Supercharged - Garage.Tech

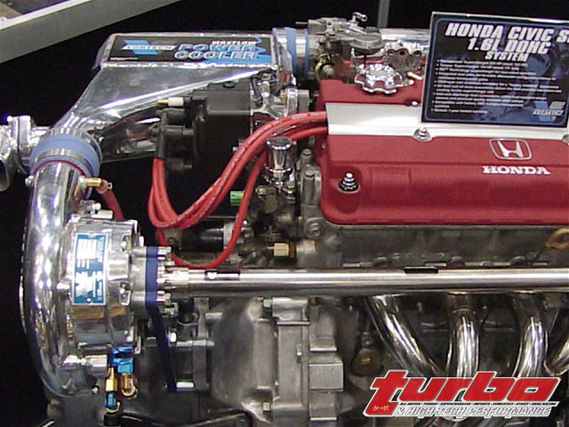

If you're a regular Turbo reader, you're probably a fan of forced induction, most likely of the turbocharged variety. Turbochargers are perhaps the greatest producers of raw power due to their penchant for using waste energy to produce additional power. The turbo's pure efficiency of getting something for nothing is an irresistible draw to technical gearheads. Turbochargers have a history of making so much power that they're often either heavily restricted or outright banned in nearly every form of motorsports. As such, it's only fair that we give superchargers equal billing. Superchargers have many advantages over turbos, some obvious and some that require a closer look.

What Is A Supercharger?

To make power, an engine burns a mixture of fuel (usually gasoline) and oxygen in its cylinders. The heat and expansion created by this burning drive the piston and connecting rod downward, turning the crankshaft and making useable power. The supercharger uses a compressor that's driven directly off the engine's crankshaft to pressurize the intake air charge. By pressurizing the charge, density is increased thus increasing the oxygen content of the intake mixture. Since more oxygen is now being induced into the engine's cylinders additional fuel can be too. This denser mixture of fuel and oxygen releases more explosive power during the combustion event. Simply put, a supercharger is like stuffing a bigger engine into the same space occupied by something once smaller.

| The Eaton supercharger's more efficient because, unlike classic roots lobed vane blowers, it has spiral vanes. The spiral vanes, when combined with carefully located and timed inlet and outlet ports, produce internal compression. The bypass valve and port shown here in the upper part of this cutaway allows air to recirculate around the blower at part throttle to cut pumping losses and improve fuel economy when cruising.

| The Eaton supercharger's more efficient because, unlike classic roots lobed vane blowers, it has spiral vanes. The spiral vanes, when combined with carefully located and timed inlet and outlet ports, produce internal compression. The bypass valve and port shown here in the upper part of this cutaway allows air to recirculate around the blower at part throttle to cut pumping losses and improve fuel economy when cruising.

Although they generally cannot generate the raw power of turbochargers, superchargers are an excellent choice for a streetable power upgrade. One of the biggest advantages of a supercharger kit is that it is one of the largest power adders that you can buy and add to your car in a weekend. A bolt-on supercharger kit can add 40-150 whp at once. Although supercharger kits are relatively expensive, they are still a good bang for the buck when considering the power-adding factor.

It's Not Easy Being Green

Kermit used to bitch about this and so do many of those who opt for aftermarket turbo kits. The most-enticing thing about supercharging is the possibility of it being 50-state street-legal. A CARB-approved supercharger kit is probably the most powerful street-legal power adder one can get. Period. Supercharger kits are easier in terms of passing emissions tests when compared to turbo systems because they don't affect the light-off time of the catalytic converter after cold starts. Turbos place turbine blades and exhaust housings, essentially a heatsink made of cold iron, in front of the cat, delaying the exhaust heat transfer needed to kick off the essential pollution-eliminating oxidation-reduction reaction going on inside. Usually cats are lit off within 30 seconds of a cold-start but a turbo can easily quadruple that time. As 90 percent of a vehicle's total emissions are created in the cold-start part of the federal emissions drive cycle, this seemingly small delay has a huge effect on the total overall emissions output during certification. Because many supercharger kits on the market are either CARB approved or are in the process of obtaining CARB approval, there is less hassle when it comes time to smog your car if your state is one that demands a visual inspection with your smog check. Even if you only have to pass a tailpipe smog check, a supercharger affects emissions less than many other mods. In this age of regulation, this is a significant advantage.

| Whipple superchargers have spiral vanes with tight helixes for lots of internal compression, making them the most efficient superchargers.

| Whipple superchargers have spiral vanes with tight helixes for lots of internal compression, making them the most efficient superchargers.

More Boost, Less Waiting

One of the biggest disadvantages of turbochargers is that they're essentially gas turbines driven by the exhaust stream. In order for a turbo to make boost pressure, the engine has to generate enough exhaust energy to spin the turbine wheel. This waiting period can take so long that it's actually been given a name: turbo lag. Turbo lag, especially with big, high-powered turbos, can be considerable. A turbo car's throttle response before the boost comes on can be lackluster. Much of the engineering that goes into turbo systems considers ways to reduce this. When a turbo does spool up, the power increase, especially with bigger turbos, tends to be rapid and non-linear. This just isn't the progressive, steady increase of power most drivers prefer.

A supercharger's primary performance advantage over the turbo is its progressive build-up of power with little discernable lag. A supercharger simply feels like a bigger, more powerful engine. In contrast, a turbo usually feels flat off idle with a sudden rush of power as things spool up. From a driveability standpoint, the steady, linear build up of power is, in many cases, more desirable than the wait and frenzied rush of a turbo.

Superchargers' response characteristics are inherent by design. Being driven directly off the crankshaft, there is a direct 1:1 correspondence between engine speed and how much additional air will be delivered to the engine. There's no lag and no waiting for the pressurized air to be delivered to the waiting cylinders.

In all-out racing applications, turbochargers are the undisputed power champs. The rules of thermodynamics dictate this. It takes a considerable amount of power to compress a large amount of air. To generate enough airflow to produce 1,000 hp from your EVO would require sacrificing about 80-120 whp just to turn the compressor. A turbocharger recovers most of this power as waste heat that would otherwise go out the tailpipe. A supercharger takes this power from the crankshaft, subtracting its power requirements from the total. This is called a parasitic loss and is why, especially with high-powered applications, the turbo always wins.

| The Eaton's triangular-shaped discharge port flanked by twin slots helps reduce the blower's more conventional whining noise as well helps increase internal compression.

| The Eaton's triangular-shaped discharge port flanked by twin slots helps reduce the blower's more conventional whining noise as well helps increase internal compression.

Well what about Top Fuel drag cars, you might ask. Since these undisputed power champions are supercharged with huge blowers, you might think there are exceptions to the rule; actually there are none in this case. The blower on a Top Fuel car can suck up to 800 hp from the crank! A Top Fuel car is chemically boosted from the oxidizer in its nitromethane-based fuel in addition to the blower. If turbos were allowed in Top Fuel, they would only make more power.

Interestingly enough, where a supercharger might reveal a power advantage over a turbo is in low-boost, street-type applications. This is because a street supercharger, despite its 10-20hp drag on the crankshaft, doesn't have the backpressure-inducing turbine that a turbocharger has in the exhaust stream. Street-type turbo systems typically have smaller compressor wheels and smaller exhaust housings in hopes of lessening lag and quickening spool up. Small turbines and housings induce a lot of backpressure, typically one and a half to two times the boost pressure. As a result, because of its much lower exhaust backpressure, a supercharger can yield better volumetric efficiency and a greater power potential than a small, quick-spooling, low-boost turbocharger. The turbocharger's big advantages of superior compressor adiabatic efficiency and waste energy usage usually do not come into play until larger, less-restrictive turbine turbochargers are fitted and higher boost levels (8 psi and up) are realized.

| The roots blower's bulky shape and long discharge slot makes intercooling difficult. Here, a small water-to-air intercooler is placed in the plenum below a roots blower.

| The roots blower's bulky shape and long discharge slot makes intercooling difficult. Here, a small water-to-air intercooler is placed in the plenum below a roots blower.

There are two types of superchargers commonly found in the aftermarket: positive displacement superchargers like the Eaton roots supercharger and centrifugal superchargers like the Vortech, Procharger, Rotrex, Paxton, HKS and Powerdyne systems. Both have totally different power characteristics. It's important to understand those characteristics for you to choose which type best suits your needs. On a side note, there's also the enigmatic Lysholm supercharger, a system with a lot of potential but with few applications.

Positive Displacement Superchargers

Positive displacement superchargers begin by taking a fixed volume of air in a chamber and moving it into a second chamber at a rate higher than the second area can be emptied. This backup of air results in pressurization of the air inside the second chamber thus increasing its density. The amount the air moves depends on the volume of the first chamber and how quickly and how many times the chamber's filled and its contents transferred. The difference between the volume of air pumped by the supercharger and the volume of air consumed by the engine is how positive displacement superchargers achieve positive manifold pressure. Such superchargers are often called "blowers" in hot-rodder lingo.

The advantage of positive displacement type blowers are their immediate and proportional boost response in relation to the throttle; such blowers consistently pump a given, constant volume of air despite engine speeds. Of course, there are slight variations in boost pressure as a blower's and an engine's volumetric efficiency improves and declines alongside engine speed throughout the powerband but, for the most part, boost pressure remains fairly constant. This makes a positive displacement blown motor feel like you're packing a much bigger engine than you are.

| Some centrifugal blower's step-up drives are belt driven to avoid whining sounds typically associated with gear drives.

| Some centrifugal blower's step-up drives are belt driven to avoid whining sounds typically associated with gear drives.

Because of these characteristics, a positive displacement supercharger is the king of driveability and low-rpm power-the perfect characteristics for a daily driver or for those who value low-end grunt. Such grunt is welcomed in high-revving, small-displacement engines like Honda's B16A and B18C. The constant delivery of boost pressure makes for an engine with smooth, linear power delivery characteristics making the positive displacement blower ideal for the driver who values a 1:1 relationship between the gas pedal and the amount of power produced. Autocrossers who need smooth predictable power from very low speeds to help throttle steer through tight cones or a person who just wants a tractable, predictable street-driven car with plenty of right-now, no-waiting punch to quickly end stoplight encounters will appreciate it too.

Roots blowers are the most common positive displacement superchargers. They're found in industrial applications like school buses, stationary engines such as generators, industrial compressors and air pumps. A roots blower has rotating, intermeshing lobes that displace a greater amount of air than the engine does. This is due to both the blower's pumping volume and stepped-up rotor-drive ratio, which is usually around two to three times the crankshaft speed. The roots blower does have some disadvantages besides the obvious parasitic loses though. Its large internal volume means that the blower has to be big and bulky, making it difficult to package near a crank drive in a tight engine compartment. Its size, shape and long discharge plenum also means it's difficult to intercool.

| A closer look inside reveals the similarities between centrifugal blowers and a turbocharger's compressor side.

| A closer look inside reveals the similarities between centrifugal blowers and a turbocharger's compressor side.

But its biggest disadvantage from a performance standpoint is that it has the lowest adiabatic efficiency among any commonly available supercharger in the order of 50 to 60 percent. When air is compressed, it heats up as expressed by the ideal gas law, PV=NrT. Adiabatic efficiency is the difference between how much the actual discharge temperature of air compressed by the supercharger rises versus the theoretical calculated temperature gain dictated by the ideal gas law. Good adiabatic efficiency is important to tuners because the higher it is, the cooler and denser the intake charge will be. A higher efficiency blower will also steal less power from the crank to make an equal amount of boost pressure.

The fact that roots blowers are external compression devices by design makes them less efficient. As a roots blower's lobes move air from the intake chamber to the intake manifold, the backed-up high-pressure air in the manifold remains at a higher pressure than the air being moved by the blower. When spinning lobes discharge the air into the manifold, the higher-pressure air momentarily tries to rush back through the lobes where it's pumped back into the manifold again. A portion of the air moving into the engine gets thrashed by the lobes, picking up heat with each trip. Not good!

Although many aftermarket companies make roots-type blowers, Eaton makes the one with the greatest number of applications on the market. The Eaton blower is a well-engineered, proven piece. Since it's built as an OEM part for several different manufactures including Nissan, Pontiac and Saturn, Eatons have undergone extensive testing for reliability and durability. Such credentials perhaps make Eatons the most reliable superchargers on the market. Eaton superchargers also have adiabatic efficiencies of more than 60 percent compared to the typical 50 percent or less when considering older roots blowers.

| HKS superchargers feature superb OEM-like quality.

| HKS superchargers feature superb OEM-like quality.

The improvement in efficiency comes from several things. Eatons have closer tolerances than older roots blowers, which allows for less internal leakage. Additionally, with their precisely timed side-port intake configuration, which is much like a rotary engine or twisted rotor geometry, Eatons actually allow some compression to take place internally. Roots blowers, with their pulsating flow, are typically very noisy. The pulses sound like a sort of loud whine. The Eaton's intake porting and exit port geometry eliminate most of this noise. Parasitic losses at part throttle are also a big problem with roots blowers. Eaton has a good solution for this issue as well. At light loads and partial throttle Eaton blowers feature internal bypass valves, which keep the supercharger from boosting when vacuum is present in the intake manifold. This reduces strain on the engine and helps fuel economy at part throttle by partially decoupling the supercharger under light-load conditions, reducing parasitic drag. Once throttle is applied and vacuum drops the valve closes allowing the supercharger to produce boost.

The bypass valve doesn't perform perfectly though. When it's open, air is circulated around the supercharger, often several times before it's ingested into the engine. Each time air passes through the supercharger it picks up heat due to partial compression. Because of this recirculation, intake temperatures can soar under light-throttle loads. Such heating is not ideal for an engine to ingest and can severely heatsoak the intake tract thus affecting full-throttle power.

| The HKS compressor is extremely compact-much like an A/C compressor-this allows it to fit in tight engine compartments.

| The HKS compressor is extremely compact-much like an A/C compressor-this allows it to fit in tight engine compartments.

Centrifugal compressors work best over a rather small speed range. This means that the step-up drive ratio must be carefully selected to prevent low-rpm compressor surge. Too high of a drive ratio can easily spin the compressor into surge. This happens when the engine's flow is less than the compressor's output, causing air to back up in the intake tract. When airflow backs up, the pressure after the compressor drops and airflow resumes causing a sort of chirping sound. Severe surge can become a violent oscillation that destroys compressor thrust bearings and can even cause wheel damage.

Care must also be taken not to overdrive the compressor wheel into choke. Choke occurs when the compressor wheel's inlet vane tip's speed exceeds that of sound, which causes a marked drop in flow. Centrifugal superchargers build boost slowly at lower speeds, usually reaching maximum power and boost at redline, due to the lower gear ratio built into the supercharger's gearbox necessary to avoid overspeeding the compressor into choke or surge at high engine speeds. The faster the engine's spun, the more power you get. This gradually increasing boost curve makes centrifugal superchargers feel somewhat laggy and less responsive at low speeds when compared to roots blowers. This compromise by design is perhaps the centrifugal supercharger's biggest disadvantage.

| Centrifugal superchargers make intercooling far easier. Like a turbocharged vehicle, plumbing in either an air-to-air or liquid-to-air setup can be fairly easy.

| Centrifugal superchargers make intercooling far easier. Like a turbocharged vehicle, plumbing in either an air-to-air or liquid-to-air setup can be fairly easy.

Perhaps the most important, yet not entirely obvious, advantage of the centrifugal supercharger is the possibility of greater durability when matched with a stock engine. Most engines are not designed to receive blower treatments, especially considering some engine's higher compression ratios and pump gasoline. This increases the chances of detonation. Most late model factory pistons feature top rings located as close to the piston's crown as possible to trap fewer hydrocarbons for reduced emissions. This area is especially prone to detonation damage. A naturally aspirated engine sees its highest cylinder pressure at its torque peak. As an engine's volumetric efficiency tapers off past its torque peak, cylinder pressures also drop. Roots blowers pump a good amount of pressure into the engine at low engine speeds, which greatly increases cylinder pressures at torque peaks. This is both good and bad. It's good because more low-end torque is made. However, if cylinder pressure gets too high, engine destroying detonation will occur, especially at the torque peak.

A properly engineered centrifugal blower won't produce as much boost and cylinder pressure at low engine speeds; it won't reach peak boost at its torque peak either. It will reach its maximum flow point near the engine's redline, however, when the engine's volumetric efficiency is rapidly falling off, giving the engine a boost in airflow as cylinder pressure drops. Cylinder pressure remains lower at the engine's torque peak as well, reducing the chances of detonation. The magic of the centrifugal blower is that it adds cylinder pressure when the engine can tolerate it best, at higher engine speeds. And to partially combat parasitic losses at partial throttle, most centrifugal supercharger kits feature huge bypass valves for venting excess air from the supercharger to the atmosphere, taking much of the blower's drive load off the engine when cruising without the recirculated heat exhibited by Eaton blowers.

| HKS' newly released GT Supercharger kit for the VQ35DE. The kit's compatible with the Nissan 350Z, Infiniti FX35 and Infiniti G35 and is good for an additional, reliable 50 whp. However, with strengthened engine components, the supercharger itself can push several hundred extra horsepower out of the VQ.

| HKS' newly released GT Supercharger kit for the VQ35DE. The kit's compatible with the Nissan 350Z, Infiniti FX35 and Infiniti G35 and is good for an additional, reliable 50 whp. However, with strengthened engine components, the supercharger itself can push several hundred extra horsepower out of the VQ.

The centrifugal blower's gradual power delivery offers some advantages. On traction-limited FWD vehicles, such a powerband can sometimes be advantageous, making the car easier to drive at its limit-especially on a road course. It can also aid FWD dragstrip launches, an important factor for those using street tires. Another advantage a centrifugal supercharger has over a roots blower is the ease of which intercoolers can be packaged into the system. Since the supercharger remains separate from the engine, integrating an intercooler and plumbing in between the compressor outlet and intake manifold is relatively simple. Centrifugal blowers are also much more compact and easier to package into today's tight engine bays.

So Who Makes Them?

HKS recently introduced its GT series centrifugal supercharger. The HKS supercharger is perhaps the most compact piece on the market, taking up roughly the same space as an A/C compressor. At the moment, HKS offers applications for the Nissan 350Z, Infiniti FX35 and Infiniti G35. Featuring high-quality components and an exceedingly clean installation, the HKS system looks almost as if it was an O.E. application. The GT supercharger is currently limited to an approximate 50whp gain due to reliability concerns since HKS feels any more power could be detrimental to the stock VQ engine's lifespan. However, the GT supercharger is capable of producing several hundred more horsepower when paired with a built bottom end. The GT supercharger's most unique feature is its unique traction drive planetary roller system used to step up compressor wheel drive speeds.

HKS' unique traction drive uses a 9.44:1 gear ratio-a much higher ratio than typical when considering centrifugal superchargers-to spin the compressor wheel up to 70,000 rpm. This gear ratio step-up is accomplished through a roller system, much like the planetary gears found in an automatic transmission, except smooth rollers are used instead of gears. The rollers are preloaded between the circular outer housing of the planetary drive and the compressor wheel's centrally located drive spindle.

Special thixotropic oil in the gear case allows the smooth gears to grip and transfer drive torque between the rollers and drive spindle. The traction oil becomes thicker and more viscous under shear or slippage, providing further transmittal of drive torque. This is where the traction drive's biggest advantage comes into play. At low engine speeds and under light loads, the traction drive allows slip so the blower reaps little in terms of parasitic losses. This translates into decent part-throttle fuel economy. As engine speeds climb and the compressor wheel requires more power, the fluid thickens transferring more power to the compressor to produce more boost.

Traction drive systems are 98 percent efficient in terms of transferring drive power and soak up less power than typical gear or belt drives used by other superchargers, which are, at best, 92 percent efficient. This helps both power and fuel economy, making the GT supercharger perhaps the most fuel efficient supercharger on the market. Anyone with supercharger experience knows that they can be pretty noisy. The traction drive is silent, unlike gear drives and belts, making the HKS system unobtrusive. The HKS kits also have a pending CARB EO for 50-state legality.

Adding It Up

Supercharged engines respond to peripheral modifications just like naturally aspirated ones. Superchargers love headers, exhausts and low-restriction air intakes, usually to a higher degree than their naturally aspirated counterparts. A supercharged engine generally prefers larger header primary tubes, collectors and exhaust systems.

Supercharged engines also respond to high-performance camshafts of nearly the same spec as a naturally aspirated engine. Adjustable camshaft gears will come in handy here since supercharged engines typically like a little less overlap to prevent boost pressure from blowing out the exhaust ports. Such engines also respond well to head porting and other flow-increasing strategies. If high-boost pressures are the plan, especially with low-quality 91-octane fuel, a heavily boosted engine will appreciate lower compression forged pistons in the 8.5:1 compression range and more sophisticated engine management.

| Supercharged - Garage.Tech

| Supercharged - Garage.Tech

A supercharger is usually a more reliable way to make an equivalent amount of power than building a naturally aspirated engine. Increasing the cylinder pressure with forced induction at lower engine speeds puts a compressive stress on the rods and crankshaft. However, to make more power with a naturally aspirated engine requires a boost in engine speeds. Such high speeds puts a tensile stress on the reciprocating components of the engine that is much greater than the compressive load a supercharger adds. This simple display of physics allows superchargers to obtain impressive results with greater reliability and a lower cost in comparison to high-horsepower naturally aspirated engines. Of course, this assumes detonation is avoided and the car has sufficient cooling capacity for its intended use.

To sum things up, roots blowers have the most immediate power, which remains proportional throughout the powerband. Centrifugal blowers make the most peak power, which is achieved by gradual increases throughout the powerband, peaking near redline. And remember, superchargers produce fewer emissions than turbochargers. In short, if you aren't looking for ultimate power but instead are trying to get a large gain of tractable oomph from your engine, or if you're simply looking for a heavily modified car that still needs to pass a smog inspection, then supercharging could just be the best answer.