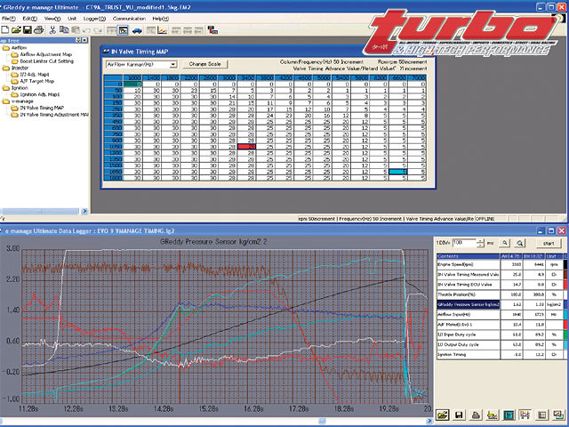

| GReddy's new v-Manage controls intake and exhaust valve timing on engines equipped with variable valve timing. Users can dynamically control timing characteristics through the PC tunable v-Manage software.

| GReddy's new v-Manage controls intake and exhaust valve timing on engines equipped with variable valve timing. Users can dynamically control timing characteristics through the PC tunable v-Manage software.

Variable valve timing is one of those things expected of today's engines. Like fuel injection, aluminum cylinder heads or four- cylinder engines with 16 valves, dynamic camshaft manipulation is more common than it's not. It isn't new though. Fiat patented the first hydraulic operated variable valve timing system in the 1960s followed by a somewhat unsuccessful attempt by General Motors a decade or so later. Most credit Nissan as being the first to implement such a system in production cars, but it was actually Alfa Romeo. It was Nissan's Valve-Timing Control System (NVCS) that garnished the notoriety though. Honda soon followed with VTEC, Mitsubishi with MIVEC, BMW with VANOS and so on. Today nearly every manufacturer offers some sort of valve timing manipulation under the hood.

| Mitsubishi wasn't the first to outfit its vehicles with variable valve timing, but its interpretation of it is arguably one of the best. MIVEC alters intake camshaft valve timing throughout the rpm range for a smooth transition from low-rpm emissions friendliness to high-rpm power output.

| Mitsubishi wasn't the first to outfit its vehicles with variable valve timing, but its interpretation of it is arguably one of the best. MIVEC alters intake camshaft valve timing throughout the rpm range for a smooth transition from low-rpm emissions friendliness to high-rpm power output.

What variable valve timing does is simple; the way it works is sort of complex. The technology allows valve timing and overlap manipulation (twin-cam) during engine operation. It's like continually swapping camshafts. While the motor's running. Multiple times. Engine's that employ Honda's i-VTEC play with both of these variables as well as alter valve lift while systems like General Motors' VVT play only with valve timing. The method by which any of these changes occur is different between manufacturers. Valve timing can be controlled hydraulically or electronically by rotating either the camshaft, its respective gear or by modifying chain tension during engine operation. The way things get done varies, but the end results are similar. Variable valve timing allows engines to burn cleaner, run smoother, yet maintain valve timing characteristics on the top end that, 20 years ago, would make for poor idling, horrible emissions and pretty bad low-rpm responsiveness.

| The EVO IX was the first to receive the updated MIVEC-equipped 4G63. The revised engine produces more horsepower and predictably lower emissions.

| The EVO IX was the first to receive the updated MIVEC-equipped 4G63. The revised engine produces more horsepower and predictably lower emissions.

OEM's equip cars with such systems to get the best of both worlds: low emissions and decent torque/horsepower output consumers will pay for. If you're interested in the torque/horsepower part of the equation then you know the valve characteristics designated by the manufacturer can be improved upon. GReddy's new v-Manage addresses this. The v-Manage allows users to manipulate valve timing characteristics on vehicles equipped with such systems for more power and in some cases improved fuel economy and emissions. The v-Manage is compatible with many manufacturers including Honda's i-VTEC, Mitsubishi's MIVEC, Toyota's VVT-i, Subaru's AVCS and Nissan's CVTC among others. The e-Manage-sized box does a few important things, most notably of which is to control the overall adjustment of the engine's valve timing map. The computer can also data log valve timing events, display them on a PC, and can be linked with any e-Manage Ultimate. If you can find your way around the e-Manage Ultimate software, learning the v-Manage will be easy.

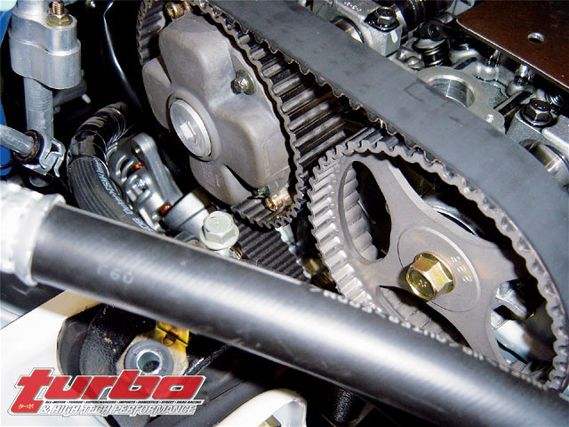

| A variable area camshaft sprocket alters intake valve timing and is triggered by an oil control valve. More conventional adjustable camshaft sprockets can also alter valve timing, but not dynamically.

| A variable area camshaft sprocket alters intake valve timing and is triggered by an oil control valve. More conventional adjustable camshaft sprockets can also alter valve timing, but not dynamically.

The v-Manage works in tandem with the factory ECM and, with nothing more than a serial cable, plugs right into any e-Manage Ultimate. Installing one is simple and consists of little more than basic wiring that anybody messing with valve timing characteristics should be able to figure out. Navigating through the software is also easy. That's because it uses the e-Manage Ultimate software, or at least an updated version of it. If you're familiar with GReddy's existing e-Manage fuel injector and ignition timing maps then working with the v-Manage's valve timing maps won't be a problem.

The v-Manage does three things you should care about: besides letting users create custom valve timing maps, it can change high-cam switchover points on engines that feature i-VTEC or VVTL-i, and it also offers valve timing data logging - not just for v-Manage-modified maps but also for OEM-configured maps. And if an e-Manage Ultimate is hooked up, valve timing can be logged and traced along with fuel and timing maps for precise tuning of all three variables. It's not uncommon to find huge power gains from cam timing adjustments. Valve timing can be adjusted independently with the v-Manage for both intake and exhaust cams or single cams. Like e-Manage fuel maps, v-Manage timing maps feature engine speed along the X-axis and four user-selectable variables along the Y-axis: throttle position, airflow, volumetric efficiency and engine temperature. Adjustments can be made to any of the map's 256 cells for both advanced or retarded valve timing.

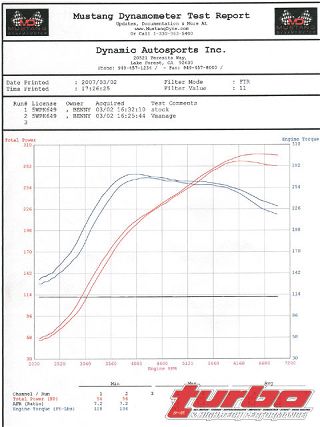

| GReddy was able to coax extra horsepower and torque out of the 4G63 through intake valve timing manipulation, nothing else. Notice the improvements across the entire graph. You need the v-Manage to do this.

| GReddy was able to coax extra horsepower and torque out of the 4G63 through intake valve timing manipulation, nothing else. Notice the improvements across the entire graph. You need the v-Manage to do this.

You won't find an engine that doesn't respond to valve timing adjustments. The valves control how much air enters the combustion chamber based on when they open, how fast they open, and how far they open. Changing any one of these events will affect power output, but not always in a good way. Everything needs to be considered before making adjustments. Turbocharged engines will respond differently than naturally aspirated engines. Adjustable camshaft timing gears are one way to make timing changes and are a good start but, unlike the v-Manage, only make static changes. The ability to change these characteristics dynamically with something like the v-Manage can prove invaluable on the dyno.

| If you've used GReddy's e-Manage Ultimate then the v-Manage software will look familiar to you. That's because it's integrated within the e-Manage program. Map adjustments, tracing and data logging: it's all the same.

| If you've used GReddy's e-Manage Ultimate then the v-Manage software will look familiar to you. That's because it's integrated within the e-Manage program. Map adjustments, tracing and data logging: it's all the same.

Four-stroke engines operate within a 720-degree cycle. When you do the math, this assumes that the intake and exhaust valves open and close every 180 degrees. They don't. On paper, this works out, but since you also have to account for the time it takes for the valve to get into position, 180 degrees won't cut it. Valves need to be opened early in order to reach full lift at the appropriate time. And closing them later allows more air to be drawn in or out while the piston dwells. A good thing. All of this extra valve timing leads to overlap, the condition in which both the intake and exhaust valves are open at the same time. It happens briefly, specifically at TDC when the intake valves are opening and the exhaust valves are closing. Overlap creates a scavenging process that allows exhaust gases to be removed quicker, making room for additional intake charge and a better cylinder fill. The v-Manage lets you do this easily. Overlap is not as conducive to forced induction though. If the exhaust valves are open during the high-pressure intake charge, it's likely to blow right past the exhaust valves, bypassing combustion. Not a good thing. Allowing the exhaust valves to open earlier and close later but keeping the intake timing more conservative generally works best for turbo applications. Like any tuning solution, the v-Manage can do wonders, but it can also get you into trouble if you don't know what you're doing.

For proof we took a look at GReddy's own EVO IX with a recently tuned v-Manage. On the dyno, simple intake timing adjustments resulted in eight additional horsepower - not bad when you consider the intake camshaft hasn't been changed, only valve timing. Torque also increased by a factor of 5 lb-ft with evident improvements across the entire powerband. As other variables like boost, compression and engine speed increase, the benefits realized through valve timing control will only show even larger improvements. It may have taken a good 40 years to perfect what Fiat started, but as they say: better late than never.