| Project NORAD Toyota Celica Part 10 - The Final Episode

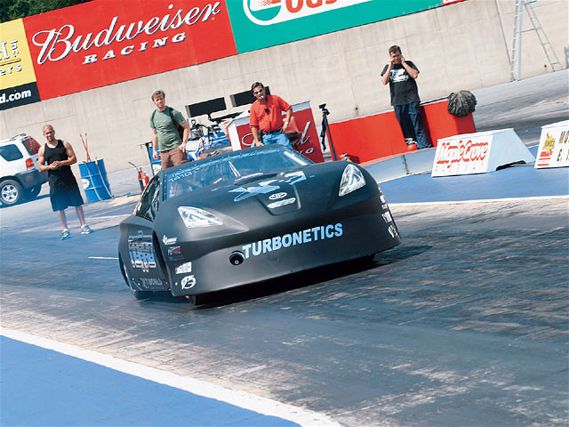

| Project NORAD Toyota Celica Part 10 - The Final Episode We've closely followed the progress of Project NORAD over the past 11 months or so and, to be honest, it has sometimes been a frustrating experience. A project like this is bound to have its ups and downs. Team NORAD started out with a center-drive chassis design that was promptly banned by the NHRA, resulting in a complete rethink of the whole concept. Delays in the construction process caused Christian Rado to miss the majority of the 2004 season but, as radical as this car is, the end result should be worth the wait. The thing is sick.

Bob Norwood and Christian Rado battled through and are finally ready to unleash the all-new NORAD Toyota Celica. The past month or so saw the crew at Norwood's shop in Texas bolstered with the full-time addition of a couple of Rado's crew members and Rado himself.

"I think it makes a lot of sense for the crew members to be involved in the final stages of the construction," Rado commented. "This is a unique racecar and this gives the crew a chance to learn the ins and outs of the car. We are also rapidly running out of time so every extra hand is needed." The lights have been burning long into the night and the entire team has been spending just about every waking hour twisting wrenches in an all-out effort to get the beast ready for action.

Nuts N' BoltsTeam crew chief and fabricator Tony Palo has been crafting all manner of parts and because of the unique design has been letting his creative juices flow. A perfect example of this is the intercooler. Starting with a Turbonetics core Palo then added a water tank on top. The water is cycled by an integral Meziere electric water pump through the cooler and is dumped back into the tank. Mounted to the end tank is a massive, custom Ford Mustang SVO 86mm throttle body, which in turn is mounted to the custom fabricated intake manifold. The lightened Turbonetics blow-off valve is also mounted directly into the intercooler. This whole assembly mounts on the chassis forward of the left front wheel where its weight can assist in maximizing traction.

Connecting the intercooler to the turbo are custom pipes secured with "Wiggins" style quick release clamps. The whole engine package is designed to allow it to be changed out in a matter of minutes.

Over on the opposite side of the chassis, the Turbonetics T88 Y2K is mounted on Palo's custom stainless-steel header system along with a pair of Turbonetics wastegates. All of the turbocharger system components have been treated with a special Calico heat-dispersant coating, hence the matte-black finish. A JAZ two-gallon fuel cell is installed on the same side to help even up the weight balance from left to right.

Before the car was rolled out of the shop the team corner-weighed it in race-ready trim with Rado strapped in the driver's seat. It was no surprise to the NORAD team when the balance was almost exactly to the original design specifications at 50/50 from side-to-side and 70/30 front-to-rear.

As the team got ready for another pull the phone rang and Rado was informed that the neighbors were complaining about the noise (What's the problem? It was only 2:30 a.m.) and they had to shut the dyno down for the night. Bummer!

Rado reserved Maple Grove Raceway track for the next day, so the team decided to resume testing on the quarter-mile dyno. As luck would have it, the team had a late start to the day and it was well into the afternoon before the Celica was lined up to make it's first pass down the quarter-mile. Wanting to make sure that the radical chassis was going to steer straight and not produce any unexpected maneuvers, Rado elected not to do a burnout. "I really just wanted to get a feel for the car and make sure that the transmission works as it should," he explained. "When I launched, it felt good and then I tried to engage second gear and nothing happened. I tried to get second several times with the same result and finally just rolled down the track." The problem was quickly diagnosed back in the pits. The compressed air bottle that supplies the Lenco was not turned on! A simple mistake that will never happen again thanks to a harsh lesson on the maiden pass.

Another problem was evident when the crew spoke to Rado after the run. Rado could not see were he was going. The one-piece front-end needed to be modified to increase driver visibility. With no time to carry out the modifications the team decided to make the next pass without the front-end.

Once again the car was started and staged without a burnout. Rado launched the car gently and to the sound of a collective sigh of relief from the crew, second gear engaged perfectly. As Rado eased into the power the cold tires spun like crazy and he shifted into third. The tires again went up in smoke as the 3RZ got into boost. The run was aborted and the team decided to make a few checks on the car.

An inspection of the cams revealed a major problem that would end proceedings for the day. One of the cast cams had snapped! "We have billet cams on order but they didn't arrive in time," Norwood explained. "With the extreme spring pressures we are running, the cast cams were a little over-stressed. We will get the new cams ASAP and be testing again at the earliest opportunity. It's not a major problem."

So, the car's first live action was not quite what the NORAD crew expected but it did provide one or two valuable lessons. Although we have reached the end of our series of stories we will still be keeping a close eye on the testing of the NORAD Celica and will update you on a regular basis.

This has been a long, hard road for Rado, Norwood and the rest of the team. With the major work now finished the crew at Norwood's are planning to start on more interesting projects including a 3RZ-powered Modified class Celica and a Scion tC being constructed to compete in the '05 National championships. The tC will also be powered by the mighty 3RZ and will feature a bulletproof Powerglide-based automatic transmission.

The NORAD Pro FWD Celica will be ready to race in the next few weeks but the team are going to treat the remainder of the 2004 season as an opportunity to test in preparation for a championship effort in '05 when the car will be re-bodied as a Scion tC.

Final words go to Norwood, "I wish I could say I was going to take a few weeks off and relax but I simply haven't got time. We have new projects waiting to start and we are going to be hard at work getting ready for '05.

One thing is for sure. The 2005 season will be a great year for the sport and I hope that NORAD will be right in the thick of the action."

The fuel system utilizes a Waterman mechanical fuel pump that is driven off of the cam. The fuel pressure regulator is a Weldon unit and the eight 1600cc injectors are sourced from the Bosch catalog. All of the fluid and pneumatic lines on Rado's missile are Goodridge G-Line XF super lightweight Kevlar items. These lines require special fittings and a purpose built crimping machine. But the weight savings on a project like this makes the extra effort worthwhile. They also look very trick!

Other last-minute tasks included the installation of the Peterson Fluid Systems five-stage oil pump and artfully crafted oil tank, the mounting of the carbon-fiber body and the fitting of the Lexan windows. At the same time, the custom-fitted seat was bolted in and the window net, fire-suppression system, harness and Diest parachute were installed.

Electronics

Probably the most labor-intensive part of the final stages of construction was the installation of the electronic systems and wiring. Once again, responsibility for this vital stage fell to Tony Palo. Rado's talented crew chief spent many hours mounting sensors, measuring wires and crimping connectors before shrink-wrapping the entire harness in Rayovac aircraft heat shrink. The list of components involved highlighting the complexity of the datalogging capabilities includes clutch pressure sensors, suspension travel sensors, complete engine function monitoring capability and a real-time knock retard system. "This was a lot more complicated than most wiring jobs," Palo commented. "We have so many different functions that we need to datalog to help us set up what is a fairly unique car. The more information we have the better."

Testing, Testing

With the car finally assembled the car was ready for its first test. Would it start? The whole crew gathered around as Rado climbed into the driver's seat and hit the starter button. A couple of revolutions of the starter and the 3RZ sputtered to life. Time for a few high-fives. A few quick tweaks of the Motec M48 ECU soon had the potent engine idling smoothly and responding nicely to throttle inputs.

Keeping a close eye on the engine's vital functions, Palo made adjustments to the Motec ECU until he was satisfied that he had a decent base-map programmed in. At this point the car was ready to be checked over and all of the fluids were drained, checked for contamination and replaced.

In an ideal world the NORAD team would have headed for the track to start the long process of fine tuning the engine, adjusting the clutch and transmission shift points and tuning the suspension. Unfortunately, Rado had a commitment to show the car at a Pepsi-sponsored show. The crew had to load the car on the rig and haul it from Texas to the east coast.

Fast-forward a week or so and the entire team is in Reading, Pa., at World Racing's headquarters. The plan is to dyno the car to get the tuning map refined and then track-test the following day at Maple Grove Raceway. A customer car was on the dyno and in typical Murphy's law fashion it had a problem and was taking far longer than expected. Eventually, late into the evening, the NORAD Celica was pushed onto the dyno and strapped down.

After a series of checks and tests the car was ready to make a low-boost 20 psi run. The engine was fired up and Rado took the car up to fourth gear. Once in fourth gear the go pedal was mashed and the 2.7-liter four-cylinder screamed like a banshee as it spun the rollers. About halfway through the run the air/fuel ratio went super-rich and Rado shut the car down.

Everyone gathered round the computer monitor as the chart was displayed. At 6000 rpm (immediately before the air/fuel ratio went rich) with 20 psi of boost the NORAD 3RZ had developed an incredible 650 horsepower at the wheels. It's worth noting that the engine is designed to generate most of its power at 10,000 rpm, with 50+ pounds of boost. The cams, head, manifolds and turbo system are all optimized for the 8,500 to 10,500 rpm range so the low-boost, low-rpm numbers are very impressive.