One of the major crossroads of tuning is determining how one will control the engine. The selection made at this point in the tuning timeline will dictate the number of engine operating parameters you have control over, and further, the amount of control you have over said parameters. The dilemma comes down to piggyback or stand-alone. Do you run the stock ECU and add peripheral computers to tweak engine performance or trash the ECU and run a programmable aftermarket ECU? A big factor is the expected power levels. But if you're stepping up to boost, engine control is even more critical.

In general, piggyback computers are more cost-effective, easier to pull off and simpler to tune. On the flip side, some piggyback computers only add fuel or control timing; not both, and they offer a limited number of tuning points. Sometimes more than one piggyback unit is necessary, which can nullify the cost advantage of this method.

Historically, stand-alones are seen as expensive, hard to understand and tune. Most of all stand-alones have the reputation of being a nightmare to wire, often requiring custom harnesses and additional sensors. Their capacities and complexity usually make them best suited for race cars. However, the leading-edge technology and high specific output of many of today's import street cars need this level of control to keep the power flowing reliably.

Advanced Engine Man-

agement (AEM) has the answer--its plug and play Engine Management System (EMS) will forever change the way serious enthusiasts look at stand-alone engine management. AEM's EMS system is a direct replacement for the factory ECU and doesn't require an additional wiring harness for operation. The application-specific system literally installs in minutes. Just unplug the harness going into the factory ECU and then plug the harness directly into the EMS unit and you're done.

The EMS has a factory base map included as well. However, AEM doesn't recommend running the vehicle with the base program. Since the needs of an individual engine is determined by its hard parts and level of modification (all-motor, boosted, nitrous-fed etc.), the base map is a starting point and each engine should be properly tuned before hitting the street. AEM also supplies the Windows-based software with the unit at no additional cost. The system also comes with a thorough a "War & Peace"-sized but user-friendly manual to educate and teach you the theories of proper tuning techniques. This manual is the most extensive we've ever seen.

Key Features

The AEM EMS unit utilizes a 16/32 hybrid high-speed processor. Sequential fuel injection allows users to run large injectors without the worry of flooding common to batch-fire engine management systems. Also, sequential injection set-ups typically have better throttle response and fuel economy.

Onboard datalogging is an added benefit of the system that is included at no extra charge as can be the case with some stand-alone systems. Datalogging duration is not limited to the EMS; the duration of the datalogging time is dependent on the memory size of the laptop. More memory equals more datalogging. On-board diagnostics is a very important feature when diagnosing a faulty injector or broken TPS. With more than 60 possible sensors and switches (depending on vehicle), you can keep down time to a minimum.

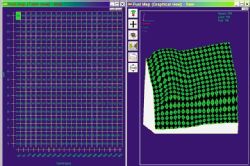

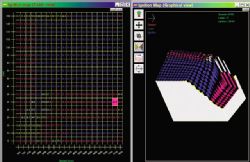

The EMS is forced induction compatible for non-factory forced induction vehicles with the addition of adapting hardware. The most important key feature is the user-friendly software. The software can be tailored to the user's preferences, making tuning much easier. Since the software is Windows(TM)-based, it enables tuners to establish their own templates of any pertinent information to view during the tuning process. And with the click of a mouse or established "quick keys," the tuner can view the user-defined templates instantly at any time.

Testing

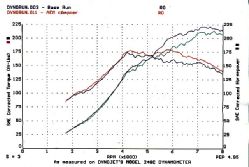

Our test vehicle was a 1995 Acura Integra GS-R with a GReddy turbo kit and front-mount intercooler. On the R&D Dynojet, the Acura registered 213.3 hp to the wheels at .65 bar (9.55 psi). However, with the Horiba meter installed, we noticed the GS-R was running extremely rich at higher rpm--running a 10.77 air/fuel ratio at one point. Installing the AEM EMS system took us a total of five minutes and John Concialdi of AEM went to work with the laptop and within only a couple of dyno pulls, we saw an increase of 7.6 peak hp, moving the overall horsepower to 220.9 at the same boost level. More importantly, we saw an improvement of more than 20 hp in the mid-range--from 5,200 rpm to 7,000, the sweet spot where the power improvements can be most felt by the equally important seat-of-the-pants dyno on the street where it counts. Concialdi spent a mere 45 minutes on the Acura, but we were sure we could easily squeeze more power out of the GS-R if we cleaned up the fuel and ignition tables a bit more.

AEM's new EMS system takes engine management to a whole new level. With the application specific hardware and the user-friendly software, the EMS system is light-years ahead of the competition. The first easy to install and easy to use system of its kind and pricing for the plug-and-play version should be around $1,800; and maybe much less. In the world of stand-alone tuning that is indeed a big bang for the buck.