Overboosting. A turbocharged engine's worst nightmare and root of disaster that claimed the life of millions of healthy engines around the world. Rewind the clock back to 2010 when my '05 Subaru Impreza STI was set to compete at Import Tuner's STI versus EVO Shootout, presented by Continental Tire. The engine was running strong prior to the event as I was determined to defend the title of fastest Subaru from the previous year's competition. During an early morning run session on the track, disaster struck. "Fire! Your STI is on fire," yelled fellow competitors as the blaze increased with intensity at every passing second. The oil fire was quickly extinguished by the Buttonwillow safety crew but not before some serious damage had occurred.

Follow along as we build this Subaru EJ25 engine from the ground up with part one of a multiple-part series that focuses on rebuilding the cylinder head. From buttoning up the bottom end using some key components to strengthen our engine to selecting the perfect turbo kit, we've got a EJ25 build that's sure to peak your interest.

Overboost Carnage

Upon returning from the event, I immediately began tearing down the EJ25 engine but not before I noticed the culprit that caused the engine's demise. The wastegate line dislodged, causing the engine to overboost. The deadly combination of 30 psi and 91-octane fuel took less than half track to cause a lean air/fuel condition that melted piston No. 4 as the car limped back to the pits in a hail of fire. Unknowing at the time, the piston failure caused extreme crankcase pressure, which in turn caused all four cam seals to push outward to relieve pressure. Without proper sealing, the Subaru engine's oil poured onto the header wrap, which immediately triggered a dramatic engine fire while returning through pit lane.

As I pulled off the RH cylinder head to survey the damage, I pulled the piston to my dismay and found the Cosworth piston severely melted.

| Project Subaru EJ25 - Part 1

| Project Subaru EJ25 - Part 1

The cylinder head looked to have received some damage; fragments of 4340 material were surrounding the cylinder head bowl. While the damage looked minimal, the main concern was if the extreme piston melting temperature was enough to also warp the head. Using a straightedge to check offered some sign of relief, but we felt the need to take the head to a machine shop for a second opinion.

| Project Subaru EJ25 - Part 1

| Project Subaru EJ25 - Part 1

| Project Subaru EJ25 - Part 1

| Project Subaru EJ25 - Part 1

Build It Right The First Time

Three years is a long time to find the right parts to build any engine, but in doing so, we had plenty of time to research the right machine shop. The last thing you want is a hack machinist who does more harm than good with your parts. So what do you look for in a good machine shop?

First and foremost, the most important thing you want to address is knowing how you plan to drive your vehicle (time attack, drag, autocross) before you start your project. All too often we hear about customers wanting an engine that spins to 8,000 rpm and delivers 500 hp on pump gas. That sounds like the ultimate engine package—but with expectation comes the added price tag.

With such a wide spectrum from which to choose, selecting a machine shop for your engine rebuild can be confusing. Your choice ranges between a one-man operation to a full-blown shop that employs over a dozen people. Which is right for you? The following will prepare you in choosing the ideal machine shop. We contacted Tom Fujita of Port Flow Design located in Harbor City, CA.

Cylinder Head Upgrades

Port Flow is one of the leading authorities in cylinder head performance. Tom's expertise was derived from working under Nissan Motorsports as an engineer under their IMSA program. His clientele is extensive and consists of current and former SCCA, NASCAR, and NHRA competitors who rely on his quality machines and workmanship. Since the STI will continue to be driven on the streets, we weren't going for a monster cylinder head port that would ultimately kill our low to midrange horsepower and response. Tom began by cleaning up the heads before performing a radius valve job.

| Project Subaru EJ25 - Part 1

| Project Subaru EJ25 - Part 1

Valve Job

A radius valve job consists of cutting the seats with a special carbide cutter. This cutter is specially made with the best angles already shaped into the cutter to ensure you get the perfect seats. This is a substantial improvement over three- and five-angle valve jobs, which are known to leave ridges at the edges of the angles. The "radius" seat eliminates the ridges and leaves a very smooth surface.

| Project Subaru EJ25 - Part 1

| Project Subaru EJ25 - Part 1

Pocket Port

The next step was performing a pocket port. Pocket porting is a term often used to describe opening the throat to a predetermined size and blending from the bottom of the valve seat to the bowl area without changing the shape or size of the port. A pocket port is used to clean up any casting imperfections surrounding the base of the valveguide. Many experienced machinists will tell you that this procedure will offer significant increase in flow and engine performance.

| Project Subaru EJ25 - Part 1

| Project Subaru EJ25 - Part 1

Resurfacing

The quality of how well your cylinder head is resurfaced often determines how long your engine will last. A head gasket needs a surface finish that will allow it to seal properly. Surfaces that are too rough or too smooth will result in the gasket not sealing properly, causing it to leak. Port Flow maintains an exceptionally smooth finish, thanks in part to their quality resurfacing equipment.

| Project Subaru EJ25 Head Gasket Surfacing 08

| Project Subaru EJ25 Head Gasket Surfacing 08

Match Port

Prior to assembly, we took the opportunity to clean up the ports without altering the shape of the bowl. Too often do we see enthusiasts become overzealous with the "bigger is better" mentality and begin grinding away at the ports, only to realize that their car runs like absolute garbage with little to no throttle response. It takes years of experience and know-how to be a top-notch cylinder head expert who is able to analyze a port and modify it to produce amazing flow levels.

| Project Subaru EJ25 - Part 1

| Project Subaru EJ25 - Part 1

Kelford Camshafts

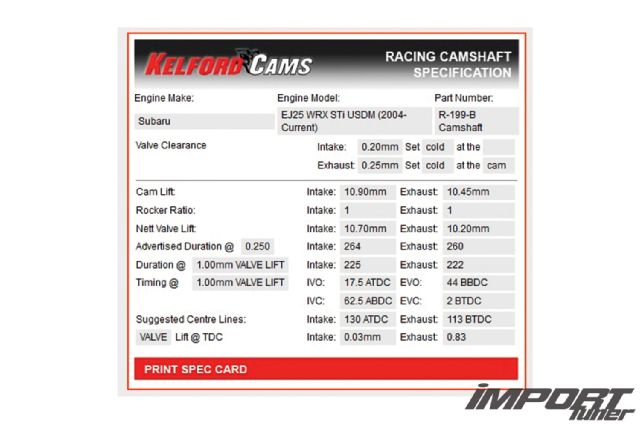

While Kelford Cams is a relatively unknown name in the U.S. Honda market, they are by no means new to the camshaft industry. Since 1968, Kelford Cams, located in Christchurch, New Zealand, has specialized in custom camshaft design and manufacturing for all types of engines, and currently supplies cams to the infamous AMS Performance time-attack Evo X. Kelford Cams' Stage 2 camshafts for the Ej25 STI USDM ('04 to current) are considered mild enough to be driven on the street, with a fractionally larger cam profile over the OEM bumpsticks for added performance. With a 264/260 duration and 10.70mm/10.20mm lift, these cams come recommended by Kelford for usage in the power range of 300 to 500 hp and 30 psi max .The main lobes on the camshafts are engineered with a profile that's easy on valvetrain components and is recommended to be used with Kelford's performance valvesprings and retainers.

| Project Subaru EJ25 Racing Camshaft Specification 10

| Project Subaru EJ25 Racing Camshaft Specification 10

| Project Subaru EJ25 - Part 1

| Project Subaru EJ25 - Part 1

Supertech Valvetrain

While reworking the cylinder head, we installed a complete Supertech valvetrain assembly. A set of stainless intake valves and inconel exhaust valves replaced the factory units and are recommended for turbocharged engines that reach very high temperatures. Supertech also offers Chrome-Molybdenum-Vanadium alloy cam buckets in various sizes when swapping out your camshafts.

| Project Subaru EJ25 - Part 1

| Project Subaru EJ25 - Part 1

The final puzzle to our valvetrain piece was a set of Supertech valvesprings, which are made with premium Superclean Chrome Silicon Vanadium Steel alloy for higher performance and withstand fatigue for long durability under extreme conditions. The added titanium retainers are manufactured with high-quality alloy, and CNC machined for proper fitment.

Cylinder Head Assembly

Bluemoon Performance, located in Costa Mesa, CA, helped out during the assembly of the cylinder head. Shingo, with over 25 years of automotive repair and tuning experience, was known as a master Toyota technician in Japan but has experience in all imports, ranging from old and new, domestics, classics, and euros. His current shop builds race engines and chassis construction for drift and time-attack vehicles in the United States, including the A'pexi SC430 driven by Patrick Mordaunt.

| Project Subaru EJ25 - Part 1

| Project Subaru EJ25 - Part 1

Camshaft Clearance

Although the Kelford camshafts were designed as a direct drop in, we felt the need to clearance the cam caps and bucket areas for the increased duration. Notice how close they were to coming in contact with the cam cap/girdle.

When you're building as many Subaru engines as us, you tend to start collecting cam buckets (as shown in the photo). These buckets come in handy when upgrading to a larger camshaft profile.

| Project Subaru EJ25 - Part 1

| Project Subaru EJ25 - Part 1

Bluemoon Performance carefully lashed the camshafts for clearance before measuring each bucket for proper clearance. This is considered one of the most painstaking tasks and often should be left to the machine.

| Project Subaru EJ25 - Part 1

| Project Subaru EJ25 - Part 1

Here's a close-up of the cylinder heads upon completion.

| Project Subaru EJ25 - Part 1

| Project Subaru EJ25 - Part 1

Intake Manifold Porting and Polishing

Porting and polishing an engine's intake manifold is an essential step in optimizing its performance, particularly if it is modified. For DIY porting amateurs, we once again recommend port matching. The resulting mismatch causes congestion of the air/fuel mixture as it travels toward the intake valve, which slows down the velocity of the airflow. We used an electric die grinder, carbide bits, a long shank, abrasives, sanding/cartridge rolls, and flap wheels, which you can purchase at your local industrial hardware store.

| Project Subaru EJ25 - Part 1

| Project Subaru EJ25 - Part 1

The main focus is to not make the port shaped like a balloon. The bulge slows the airflow (the cross-section becomes larger), and this causes the airflow to "stack up" behind the slowed flow and create turbulence, which is harmful to good flow. With a little planning, the proper tools, and some patience, the average DIYer can clear up this congestion by port matching (gasket match) the intake manifold to enable your engine to breathe easier.

| Project Subaru EJ25 - Part 1

| Project Subaru EJ25 - Part 1

We polished the insides of the intake manifold with a finer 120- to 180-grit flap wheel as we progressed. With any engine modification we recommend an experienced mechanic or machinist to properly port your parts. The same porting was applied to the factory TGV (tumble valveguides) to wrap up the upgraded cylinder heads' portion of the build.

| Project Subaru EJ25 - Part 1

| Project Subaru EJ25 - Part 1