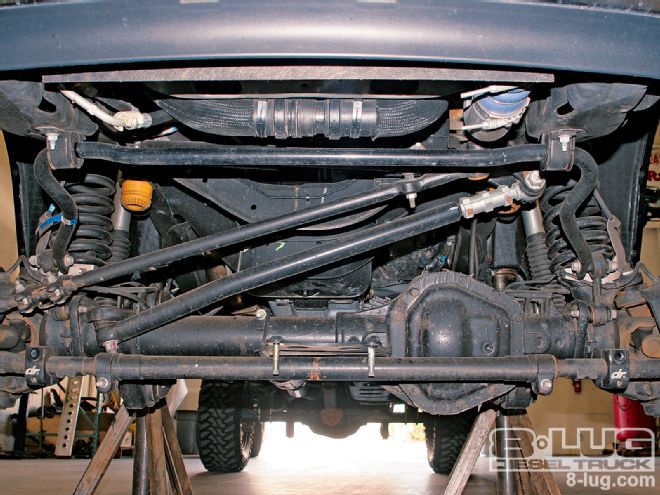

The Super Duty pickup is a beast that looks great lifted, and that extra space will not only allow for larger wheels and tires, but will give the four-wheel-drive truck the ability to easily traverse large rocks and deep gullies.

| The Icon 4.5-inch lift kit supplies everything that is necessary to give the Super Duty some much-needed air.

The owner of this ’07 Ford F-250 Super Duty is a horse rider, and as such, pulls a loaded horse trailer. Due to the fact that horse trailers are low to the ground, he wanted to lift his truck, but not to the extreme. That is why he chose to go with the Icon 4.5-inch lift kit. The Icon kit will give him the look and height he’s shooting for without having a problem with the trailer. Sure, there are hitches with huge drops, but he didn’t want to use one any longer than he had to. That is why the 4.5-inch Icon kit would be perfect for his truck and his needs.

Though the Icon brand may be a new company in terms of time in business, they have years of experience with suspension (both race and lift kits) in that they have taken over for the now defunct Donahoe Racing. What remains is the race-bred knowledge on suspension and suspension-design techniques.

The Icon kit that will be installed here is the 4.5-inch lift kit. Ford saw fit (and bless them for it) to finally equip their four-wheel-drive trucks with coil springs rather than the old leaf spring pack. In addition to the various drop brackets, the Icon kit replaces the stock coil springs with longer, and more importantly, progressive-rate springs. A progressive-rate spring will provide a softer ride during the initial few inches of travel, and then will stiffen up as the suspension progresses through its arc. Those springs have been matched with Icon 2.5 shocks, which have been valved specifically for the big Ford to give the Super Duty the best ride possible both on- and off-road.

The install was completed at Icon’s Corona, California, headquarters and as the Icon crew are experts, they got the job done in quick order. But this is not a real difficult task, and your local shop should be able to have the Icon kit installed in about 4 hours.

So follow along as this big Ford gets even bigger, and a lot better, all at the same time.

In The Can

What’s Inside an Icon 2.5-inch Smoothie?

The inner workings of shock absorbers has always been a mystery to some, and a way of winning races for those in the know. Suffice to say that like many other things, shocks are both basic and complicated. They are simple in that they force oil through a series of shims (or valves) to control the shock’s movement in a metered way. Working in conjunction with the spring (which also provides both compression and rebounding characteristics), the shock absorbs and reacts to the bumps found in the road. Simple, right?

| All Icon shocks are handmade in their Corona, California, facility.

It sure sounds that way, but it’s not. The inside of a shock absorber has changed much over the years, and no one improvement has been more important than that of the addition of nitrogen gas. Being inert, the nitrogen gas doesn’t get hot like the oil does, which keeps the valving stable, even during the hardest running. The problem with an all-oil shock is that it would foam up during hard running and the valving would become virtually non-existent. With the nitrogen keeping the oil under pressure, that heating and foaming is not nearly as prominent, so the valving action of the shock remains constant.

Icon produces their own line of shocks, and we were able to follow along as one of their 2.5 Smooth Body (Part #6-7501-25) shocks was built. They are all built at their Corona, California, facility with pieces made in the USA. Those pieces include a cadmium-plated steel body (1026 DOM), and a shaft that is 7/8-inch nitrite steel (to prevent pitting and rusting). The all-aluminum pieces are hard-anodized and all of the set screws are made from stainless steel. The shaft travel of this shock is 9.25 inches.

| The Icon 2.5 shock is more than the sum of its parts…but you have to start somewhere.

It features a two-piece piston (one for compression and one for rebound) that features a digressive piston design to preload valve shims. This digressive design allows the shock to not have to “break the static load”, which is shock-builder speak which means when the shock is not moving at all and has to start moving. All of which makes for a more sensitive and faster-reacting shock.

Icon takes a lot of pride in their shocks, and seeing how they produce one, they should. The pieces they use are all first-rate and as stated, the best part is that they are made in the USA.