| chevy S10 engine Swap

Stuffing a V-8 into an S-10 isn't something new. Since these trucks were introduced, grease monkeys have been ditching the stock motors for the grunt of a small-block. Back in the day, parts would have to be cobbled together or fabricated from scratch to make it work. Now things are a little easier. The Hedman Performance Group, which consists of Hedman Hedders, Trans-Dapt, and Hamburger's oil pans, put its collective minds together and built a set of parts which work together to swap a small-block into these little trucks.

The motor-mount kit is designed to install a 283-350 or LT1 Chevy engine into any 2WD Chevy Blazer, Sonoma or S-10, GMC Jimmy, or S-15. The mounting brackets are laser-cut using 5/16-inch-thick steel. The bolts are Grade 8 and yellow-zinc-plated for durability. The mounts will raise the motor up one inch if left alone, but you can trim off the bottom ear and put the motor at stock height. If you run it at stock height, you'll have to use a set of stock exhaust manifolds. Untrimmed, the mounts are specifically designed to be used with Hedman Hedders Engine Swap Hedders.

Hedman offer three tiers of Hedders for this: standard-duty uncoated, standard-duty HTC-coated, and Elite (ones covered in this story). The Elite line is a heavy-duty set of pipes with 1-1/2-inch mandrel-bent 14-gauge tubes, 3/8-inch flanges, a 2-1/2-inch collector, and a matte-finish ceramic-metallic coating. The big difference between standard-duty and Elite is the wall thickness. Standard-duty headers typically use 18-gauge, while the Elites are 14-gauge.

Just like the other parts, the high-performance oil pan is designed specifically for this swap and works on both 2WD and 4WD models. The pan has notched side rails to accommodate stroked engines, and it offers a 7-quart capacity (including 1 quart in the filter). The pan comes with the proper oil pick-up and a set of special gaskets that follow the notched side-rail profile. Since this pan has the notched rails, we grabbed a set of oil-pan spreader bars to provide better load-force distribution along the perimeter of the oil pan.

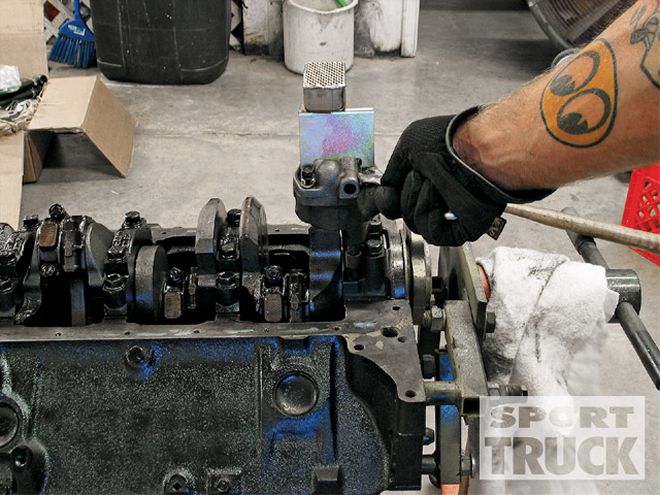

We flew out to Midwest Images in New Baden, Illinois, and met up with Mike Cotten to perform and document the bare-bones method of getting this motor into a first-generation S-10. If we did it on a California truck, we would have to get it past the smog referee and that's just a pain. Mike's truck came from the factory with a 2.8L V-6, but the theme of the build was more on target with a retro muscle car. A little V-6 wouldn't be up to par with that theme, so a Mouse motor needed to be stuffed under the hood. We also did a four-link rear setup with some fat tires (also in this issue) so we could hook up with all this new power. Check out how the kit helped us install a semi-mild 355ci engine Mike had at his shop.

| chevy S10 engine Swap

Stuffing a V-8 into an S-10 isn't something new. Since these trucks were introduced, grease monkeys have been ditching the stock motors for the grunt of a small-block. Back in the day, parts would have to be cobbled together or fabricated from scratch to make it work. Now things are a little easier. The Hedman Performance Group, which consists of Hedman Hedders, Trans-Dapt, and Hamburger's oil pans, put its collective minds together and built a set of parts which work together to swap a small-block into these little trucks.

The motor-mount kit is designed to install a 283-350 or LT1 Chevy engine into any 2WD Chevy Blazer, Sonoma or S-10, GMC Jimmy, or S-15. The mounting brackets are laser-cut using 5/16-inch-thick steel. The bolts are Grade 8 and yellow-zinc-plated for durability. The mounts will raise the motor up one inch if left alone, but you can trim off the bottom ear and put the motor at stock height. If you run it at stock height, you'll have to use a set of stock exhaust manifolds. Untrimmed, the mounts are specifically designed to be used with Hedman Hedders Engine Swap Hedders.

Hedman offer three tiers of Hedders for this: standard-duty uncoated, standard-duty HTC-coated, and Elite (ones covered in this story). The Elite line is a heavy-duty set of pipes with 1-1/2-inch mandrel-bent 14-gauge tubes, 3/8-inch flanges, a 2-1/2-inch collector, and a matte-finish ceramic-metallic coating. The big difference between standard-duty and Elite is the wall thickness. Standard-duty headers typically use 18-gauge, while the Elites are 14-gauge.

Just like the other parts, the high-performance oil pan is designed specifically for this swap and works on both 2WD and 4WD models. The pan has notched side rails to accommodate stroked engines, and it offers a 7-quart capacity (including 1 quart in the filter). The pan comes with the proper oil pick-up and a set of special gaskets that follow the notched side-rail profile. Since this pan has the notched rails, we grabbed a set of oil-pan spreader bars to provide better load-force distribution along the perimeter of the oil pan.

We flew out to Midwest Images in New Baden, Illinois, and met up with Mike Cotten to perform and document the bare-bones method of getting this motor into a first-generation S-10. If we did it on a California truck, we would have to get it past the smog referee and that's just a pain. Mike's truck came from the factory with a 2.8L V-6, but the theme of the build was more on target with a retro muscle car. A little V-6 wouldn't be up to par with that theme, so a Mouse motor needed to be stuffed under the hood. We also did a four-link rear setup with some fat tires (also in this issue) so we could hook up with all this new power. Check out how the kit helped us install a semi-mild 355ci engine Mike had at his shop.

| chevy S10 hedders

What's in the box?

| chevy S10 hedders

What's in the box?

| chevy S10 final Product

The Final Word

| chevy S10 final Product

The Final Word