Vortec Big-Block in a 1996 Chevy Truck - Head Games, Part 1

| 1996 Chevy Truck Vortec Big Block big Block

What happened to the big power numbers of the 454? The last generation big-block by GM (Vortec 454) leaves much to be desired when it comes to output. The Vortec big-block was gifted with a sequential port fuel-injection system that provided more power than its predecessor (throttle-body injection), but it still wasn't even close to the numbers found in the late-'60s and early '70s engines.

In fact, the LS6 (optional motor) that was available in 1971 was one of the highest-output 454 engines in production for its configuration. The fire-breathing Rat blew brimstone at the rate of 425 hp. Not bad for a powerplant straight off the showroom floor. The LS5 of the same year pumped out 365 hp. In 1972, all that power was lost. The LS6 was no longer available, and the LS5 only put out 270 hp.

Manufacturers are given a specified number of smog credits per year. The lineup of vehicles and quantity of vehicles manufactured consumes these credits quickly. So, you can see how making vehicles run lean and choking down the bigger engines would directly affect the company's profitability. But, that doesn't stop motorheads from seeking out ways to unleash the potential locked in the stock powerplants.

As part of the motorhead family, we at Sport Truck decided to see if we could revive some of the numbers locked away in the mystery of the Vortec big-block. We started by strapping our '96 Chevy dualie to the dyno to see how much power our Vortec engine had. After a couple pulls, the best run the Bow Tie could muster was 215 hp, and 329 lb-ft of torque.

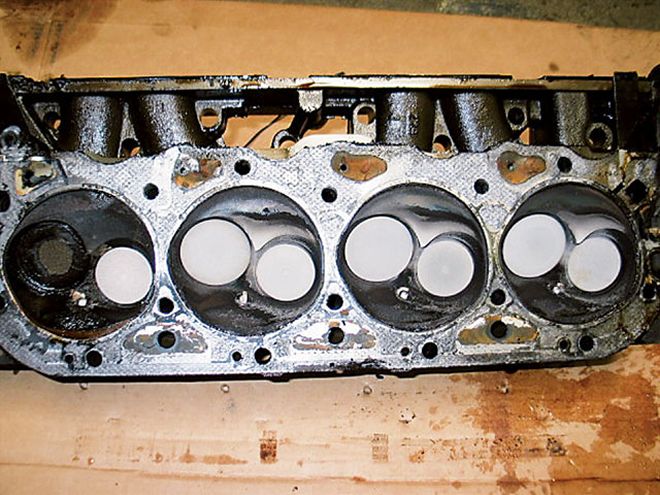

We then pulled off the top of the engine to look inside. We found what GM had done to keep the Rat at bay: If you can't breath, you can't run. The Vortec intake pockets have a ramp that is suppose to swirl the air/fuel charge to increase velocity and provide more torque. The problem is that the ramps were rough-cast and needed some work to allow the air to move over a smooth surface instead of tumble over it. The intake runners are fairly respectable and are definitely an improvement from the "Peanut" heads found on the throttle body-injected Rat GM used before the Vortec. The runners were "as cast," of course, leaving a rough surface with mold seams in the runners, reducing airflow efficiency even further. In the exhaust runner, a large bulge that shrouds the exhaust valve stem consumes about one third of the exhaust runner, making the port restrictive. We also found that the intake valve in the Vortec head is 2.060 inches in diameter, and the exhaust is 1.72 inches, which is small for a 454ci engine.

We took the heads to Superior Automotive in Anaheim, California, to have the heads flowed and ported to improve the airflow problems. Owner and founder of Superior Automotive Joe Jill and his techs tore into the heads and told us what we needed to do to make a good strong combination. The cams in these trucks are retarded by the factory about 6 degrees. So, we got Competition Cams to remedy the problem with its Ultimately Adjustable Timing Set to dial in the cam. While we had the top pulled off the engine, we opted to convert the hydraulic flat-tappet cam to a hydraulic roller and gain a few more horses. We also ordered a mildly upgraded cam with no more duration and the same centerline, but with a little more lift to take advantage of better airflow through the heads.

Superior also opened up the airflow in our Vortec heads by installing a lager set of valves. The new Manley stainless swirl valves provide more valve surface area, which enables a larger volume of air to pass through the valve openings. The head was cut to hold a 2.190 intake valve and a 1.800 exhaust valve. Superior bolted the heads to its SuperFlow SF600 flow bench to test the stock combination. The enhanced cam we got from Comp has 0.510 lift, which is about 0.060 over the stock cam. We also got a 1.8:1 rocker to enhance the cam lift. With the 1.8 rockers, the new cam lift will actually be 0.540. This meant we needed to pay attention to the flow numbers up to 0.550 lift. The stock intake flowed 246 cfm at 0.550 lift, and the exhaust flowed 162 cfm at 0.450 lift. We flowed the exhaust at 0.550, but the air in the runner started to tumble and the flow numbers started to fall off.

After the head work was done, the flow number came up across the board. At 0.550 inch of lift, the intake flows 271 cfm and the exhaust 0.204 cfm at the same lift. With the head work done, all we needed to do was assemble and break in the engine before we strapped it down to the dyno. Check in next month to see how the big Bow Tie does on the dyno after all the mods.

| 1996 Chevy Truck Vortec Big Block big Block

What happened to the big power numbers of the 454? The last generation big-block by GM (Vortec 454) leaves much to be desired when it comes to output. The Vortec big-block was gifted with a sequential port fuel-injection system that provided more power than its predecessor (throttle-body injection), but it still wasn't even close to the numbers found in the late-'60s and early '70s engines.

In fact, the LS6 (optional motor) that was available in 1971 was one of the highest-output 454 engines in production for its configuration. The fire-breathing Rat blew brimstone at the rate of 425 hp. Not bad for a powerplant straight off the showroom floor. The LS5 of the same year pumped out 365 hp. In 1972, all that power was lost. The LS6 was no longer available, and the LS5 only put out 270 hp.

Manufacturers are given a specified number of smog credits per year. The lineup of vehicles and quantity of vehicles manufactured consumes these credits quickly. So, you can see how making vehicles run lean and choking down the bigger engines would directly affect the company's profitability. But, that doesn't stop motorheads from seeking out ways to unleash the potential locked in the stock powerplants.

As part of the motorhead family, we at Sport Truck decided to see if we could revive some of the numbers locked away in the mystery of the Vortec big-block. We started by strapping our '96 Chevy dualie to the dyno to see how much power our Vortec engine had. After a couple pulls, the best run the Bow Tie could muster was 215 hp, and 329 lb-ft of torque.

We then pulled off the top of the engine to look inside. We found what GM had done to keep the Rat at bay: If you can't breath, you can't run. The Vortec intake pockets have a ramp that is suppose to swirl the air/fuel charge to increase velocity and provide more torque. The problem is that the ramps were rough-cast and needed some work to allow the air to move over a smooth surface instead of tumble over it. The intake runners are fairly respectable and are definitely an improvement from the "Peanut" heads found on the throttle body-injected Rat GM used before the Vortec. The runners were "as cast," of course, leaving a rough surface with mold seams in the runners, reducing airflow efficiency even further. In the exhaust runner, a large bulge that shrouds the exhaust valve stem consumes about one third of the exhaust runner, making the port restrictive. We also found that the intake valve in the Vortec head is 2.060 inches in diameter, and the exhaust is 1.72 inches, which is small for a 454ci engine.

We took the heads to Superior Automotive in Anaheim, California, to have the heads flowed and ported to improve the airflow problems. Owner and founder of Superior Automotive Joe Jill and his techs tore into the heads and told us what we needed to do to make a good strong combination. The cams in these trucks are retarded by the factory about 6 degrees. So, we got Competition Cams to remedy the problem with its Ultimately Adjustable Timing Set to dial in the cam. While we had the top pulled off the engine, we opted to convert the hydraulic flat-tappet cam to a hydraulic roller and gain a few more horses. We also ordered a mildly upgraded cam with no more duration and the same centerline, but with a little more lift to take advantage of better airflow through the heads.

Superior also opened up the airflow in our Vortec heads by installing a lager set of valves. The new Manley stainless swirl valves provide more valve surface area, which enables a larger volume of air to pass through the valve openings. The head was cut to hold a 2.190 intake valve and a 1.800 exhaust valve. Superior bolted the heads to its SuperFlow SF600 flow bench to test the stock combination. The enhanced cam we got from Comp has 0.510 lift, which is about 0.060 over the stock cam. We also got a 1.8:1 rocker to enhance the cam lift. With the 1.8 rockers, the new cam lift will actually be 0.540. This meant we needed to pay attention to the flow numbers up to 0.550 lift. The stock intake flowed 246 cfm at 0.550 lift, and the exhaust flowed 162 cfm at 0.450 lift. We flowed the exhaust at 0.550, but the air in the runner started to tumble and the flow numbers started to fall off.

After the head work was done, the flow number came up across the board. At 0.550 inch of lift, the intake flows 271 cfm and the exhaust 0.204 cfm at the same lift. With the head work done, all we needed to do was assemble and break in the engine before we strapped it down to the dyno. Check in next month to see how the big Bow Tie does on the dyno after all the mods.

| 1996 Chevy Truck Vortec Big Block big Block

What happened to the big power numbers of the 454? The last generation big-block by GM (Vortec 454) leaves much to be desired when it comes to output. The Vortec big-block was gifted with a sequential port fuel-injection system that provided more power than its predecessor (throttle-body injection), but it still wasn't even close to the numbers found in the late-'60s and early '70s engines.

In fact, the LS6 (optional motor) that was available in 1971 was one of the highest-output 454 engines in production for its configuration. The fire-breathing Rat blew brimstone at the rate of 425 hp. Not bad for a powerplant straight off the showroom floor. The LS5 of the same year pumped out 365 hp. In 1972, all that power was lost. The LS6 was no longer available, and the LS5 only put out 270 hp.

Manufacturers are given a specified number of smog credits per year. The lineup of vehicles and quantity of vehicles manufactured consumes these credits quickly. So, you can see how making vehicles run lean and choking down the bigger engines would directly affect the company's profitability. But, that doesn't stop motorheads from seeking out ways to unleash the potential locked in the stock powerplants.

As part of the motorhead family, we at Sport Truck decided to see if we could revive some of the numbers locked away in the mystery of the Vortec big-block. We started by strapping our '96 Chevy dualie to the dyno to see how much power our Vortec engine had. After a couple pulls, the best run the Bow Tie could muster was 215 hp, and 329 lb-ft of torque.

We then pulled off the top of the engine to look inside. We found what GM had done to keep the Rat at bay: If you can't breath, you can't run. The Vortec intake pockets have a ramp that is suppose to swirl the air/fuel charge to increase velocity and provide more torque. The problem is that the ramps were rough-cast and needed some work to allow the air to move over a smooth surface instead of tumble over it. The intake runners are fairly respectable and are definitely an improvement from the "Peanut" heads found on the throttle body-injected Rat GM used before the Vortec. The runners were "as cast," of course, leaving a rough surface with mold seams in the runners, reducing airflow efficiency even further. In the exhaust runner, a large bulge that shrouds the exhaust valve stem consumes about one third of the exhaust runner, making the port restrictive. We also found that the intake valve in the Vortec head is 2.060 inches in diameter, and the exhaust is 1.72 inches, which is small for a 454ci engine.

We took the heads to Superior Automotive in Anaheim, California, to have the heads flowed and ported to improve the airflow problems. Owner and founder of Superior Automotive Joe Jill and his techs tore into the heads and told us what we needed to do to make a good strong combination. The cams in these trucks are retarded by the factory about 6 degrees. So, we got Competition Cams to remedy the problem with its Ultimately Adjustable Timing Set to dial in the cam. While we had the top pulled off the engine, we opted to convert the hydraulic flat-tappet cam to a hydraulic roller and gain a few more horses. We also ordered a mildly upgraded cam with no more duration and the same centerline, but with a little more lift to take advantage of better airflow through the heads.

Superior also opened up the airflow in our Vortec heads by installing a lager set of valves. The new Manley stainless swirl valves provide more valve surface area, which enables a larger volume of air to pass through the valve openings. The head was cut to hold a 2.190 intake valve and a 1.800 exhaust valve. Superior bolted the heads to its SuperFlow SF600 flow bench to test the stock combination. The enhanced cam we got from Comp has 0.510 lift, which is about 0.060 over the stock cam. We also got a 1.8:1 rocker to enhance the cam lift. With the 1.8 rockers, the new cam lift will actually be 0.540. This meant we needed to pay attention to the flow numbers up to 0.550 lift. The stock intake flowed 246 cfm at 0.550 lift, and the exhaust flowed 162 cfm at 0.450 lift. We flowed the exhaust at 0.550, but the air in the runner started to tumble and the flow numbers started to fall off.

After the head work was done, the flow number came up across the board. At 0.550 inch of lift, the intake flows 271 cfm and the exhaust 0.204 cfm at the same lift. With the head work done, all we needed to do was assemble and break in the engine before we strapped it down to the dyno. Check in next month to see how the big Bow Tie does on the dyno after all the mods.