| bosch Auto Parts Tune Up Basics engine

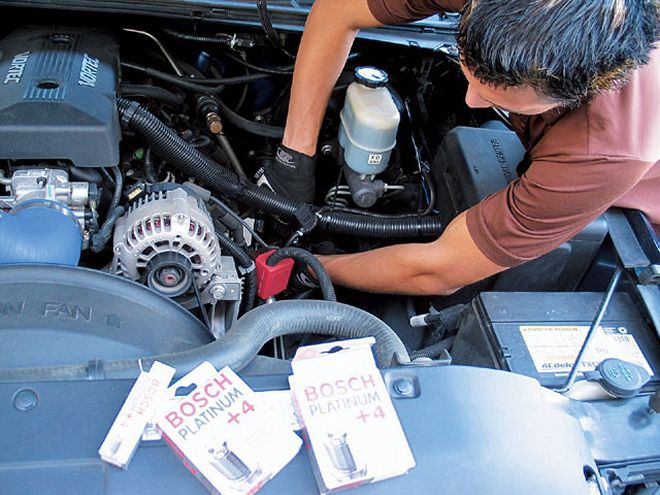

With gas prices reaching record highs, the fuel-saving benefits, as well as performance improvements, from a much-needed periodic tune-up have never been more pronounced. However, in today's automotive world of computers, converters, environmental regulations, and rapidly changing technology, exactly what is a tune-up anyway?

Many of us remember those wonderful days when a tune-up meant replacing the spark plugs, plug wires, points, rotor, and maybe the distributor cap, and checking the timing and kicking the tires. For many Sport Truck readers who are tooling around in "seasoned" vehicles, this still holds true. For most of us, however, the points, condenser, and rotor are gone forever, and you won't find a bolt to let you adjust the timing if you look all day.

| bosch Auto Parts Tune Up Basics bosch Auto Parts

Today, a tune-up normally means:Replace the spark plugs and spark plug wires (if applicable)

Check the oxygen sensors for proper operation and replace if needed

Replace the air filter, breather filter, and pcv valve

Change the oil and filter

Change the fuel filter

Check the transmission and replace fluid if needed

Inflate the tires to recommended pressure

A tune-up including these factors can show dramatic results. "Test results show fuel economy improvements of nearly 5 percent from installing new premium spark plugs, such as Bosch's Platinum +4 plugs. Replacing a worn or degraded oxygen sensor in many vehicles, especially pre-'96 trucks and cars, can often save another 5 to 10 percent of fuel. Equally important to the sport-truck driver, this can immediately improve driveability and performance." This comes directly from the Product and Technical Support Specialist with the Robert Bosch Corporation. Other research shows that replacing all worn-out or degraded oxygen sensors nationwide would reduce exhaust emissions more than all other repairs combined.

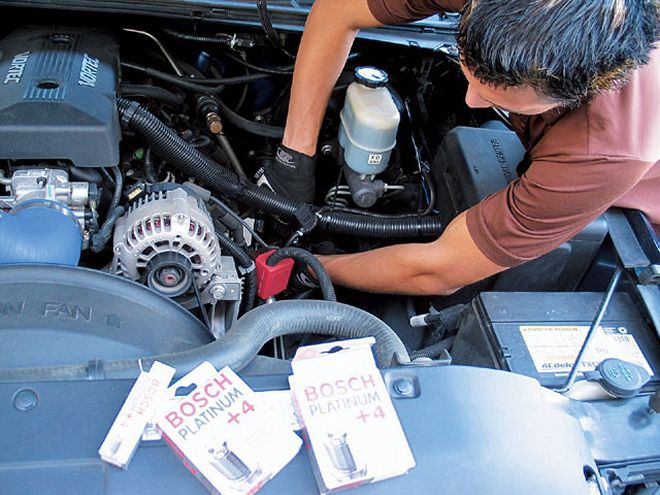

| bosch Auto Parts Tune Up Basics spark Plugs

Reading The PlugsWhen replacing spark plugs, reading the old plugs is a good way to determine the engine's general operating condition, and to detect problems. First, it is important to keep the plugs in order with the cylinders from which they were removed. The color and condition of the plug tip is an indication of combustion conditions, and plug tip conditions in a properly operating engine should be uniform for all cylinders. A tan, slightly reddish deposit on the spark plug is normal. Other colors or conditions on the tip may point to fuel, ignition, vacuum, or engine problems. For example, black and fluffy soot on the plug insulator indicates an over-rich fuel condition, which may be caused by a leaking injector or out-of-adjustment carburetor.

White deposits on the insulator typically indicate oil consumption. This may point to a failed cylinder valve oil seal, worn valve stem guide, worn or broken piston ring, or scored cylinder. Any of these failures indicates the need for internal engine repairs. Catching these problems early by reading the plugs can save you money on more expensive repairs down the line. Very-light-tan or white blistered insulators may point to a mixture that is too lean or hot. Clogged fuel injectors may cause excessively lean mixtures. A vacuum leak may also cause this condition with multiport or sequential fuel injection, as well as with throttle-body fuel injection and carburetors.

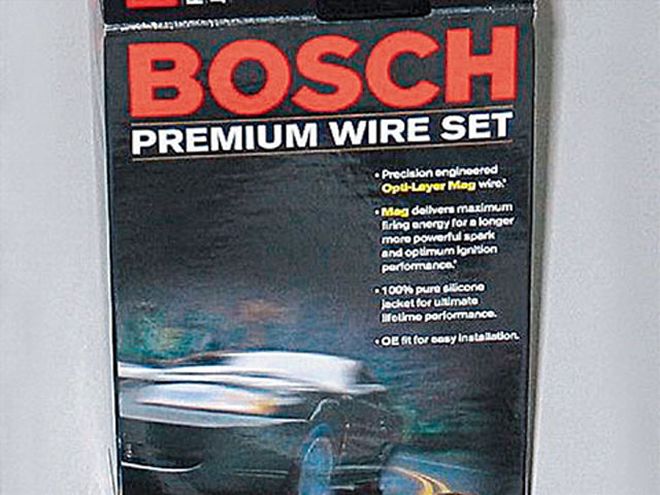

| bosch Auto Parts Tune Up Basics bosch Premium Wire Set

New Plug Wires Assure SparkIf the "juice" doesn't make it through the wires to the spark plugs, there is no spark, resulting in a dead engine. Engine heat is the primary cause of spark plug wire deterioration, which can lead to loss of continuity, or cracks in the insulation, allowing spark to arc to ground. In off-road applications, buildup of dirt and grime over time can also lead to problems with spark tracking to ground, in which case the spark may be weakened, or some plugs may not fire at all. A new set of plug wires is the best way to ensure all the intended spark reaches the plug.

Premium plug wire sets are normally precut to provide exact original-equipment fit. Bosch's Opti-Layer Mag wire features a stainless-steel core that is reinforced with Kevlar and will not break down like carbon cores in conventional plug wires. The stainless core is sheathed with EPDM inner insulation to stop voltage leaks, and then covered with a 100 percent pure-silicone jacket for lifetime protection.

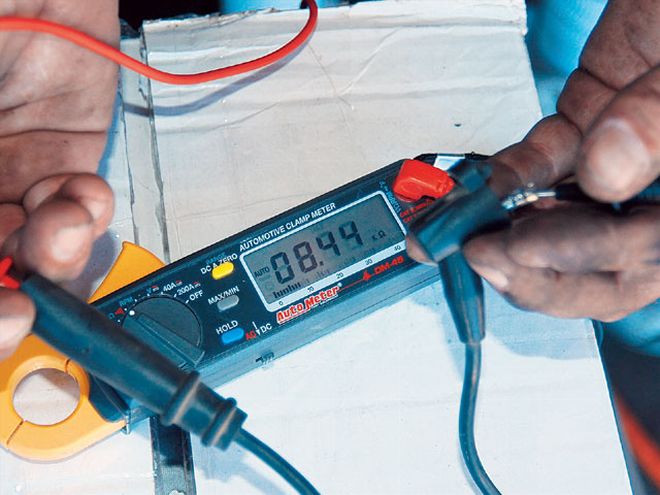

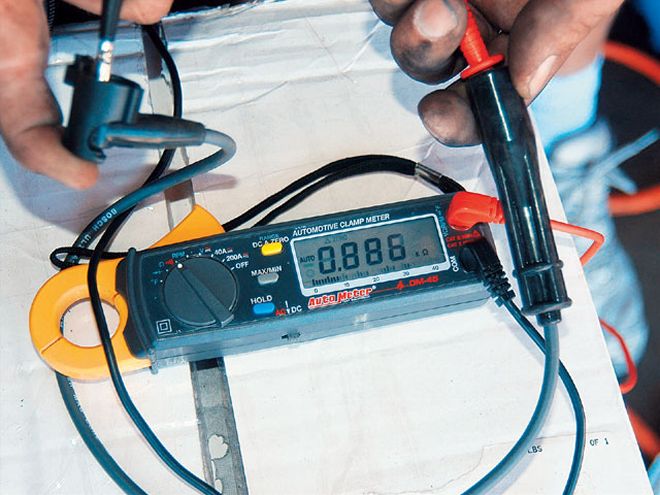

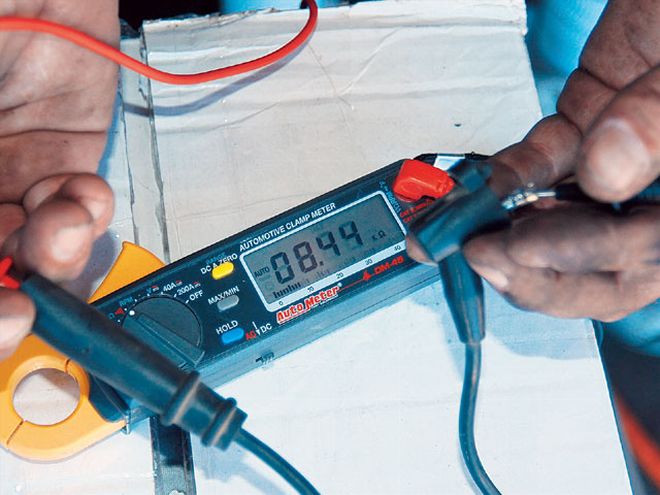

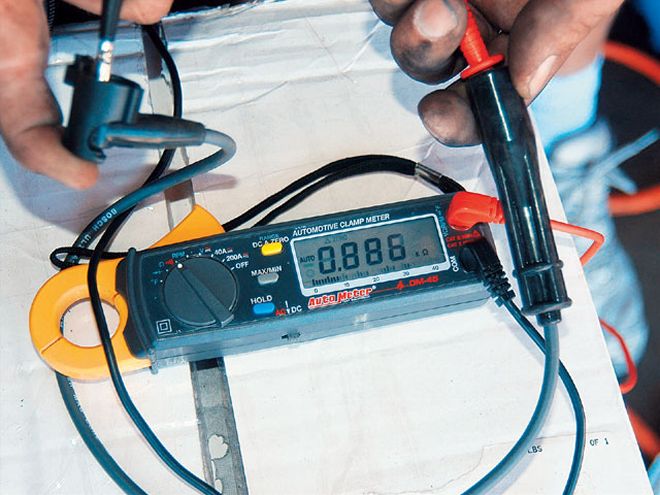

We tested the resistance of the old spark plug wires against the resistance of the new wires and we found a dramatic difference. The new wires read 0.886 kilo ohms compared with the 8.440 kilo ohms the stock wires read.

-

-

Check That O2 Sensor!The oxygen sensor measures oxygen remaining in the exhaust after combustion and relays this oxygen level to the engine computer, which fine-tunes the air/fuel mixture close to 14.7:1, otherwise known as stoichiometric, where maximum fuel economy and the lowest exhaust emissions are achieved. An engine can still run with a malfunctioning oxygen sensor, but other sensors can only ballpark the correct air/fuel mix. Therefore, the oxygen sensor is one of the most important sensors onboard.

If your truck was built before 1996 (and after 1978), it should be equipped with an oxygen sensor in each exhaust system, mounted before the catalytic converter. If it was built after 1996, when onboard diagnostics II (OBD-II) regulations went into effect, it is equipped with two O2 sensors for each exhaust bank, one before the converter and one after the converter.

Certain symptoms point to a worn-out O2 sensor, such as:

increased fuel consumption

rough running and poor performance

pre-ignition or detonation (engine knock)

fouled spark plugs, usually from an overly rich fuel/air mixture if the vehicle is not burning oil

the vehicle has failed an emissions test, usually with high CO or HC

a catalytic converter damaged byoverly rich or extremely lean fuel/air mixture

OBD-II vehicles, 1996-and-newer, will usually turn the MIL (malfunction indicator light) on when the system sees a failure or problem that will cause a 50 percent increase in tailpipe emissions. Oxygen sensors may be tested with a voltmeter. A properly functioning sensor should read about 0.5 volts. Test conditions can be induced for a rich fuel/air mix, which should produce a reading of 0.9 volts. Conditions for a lean mix should produce a reading of 0.2 volts. Heated thimble oxygen sensors, currently the predominant O2 sensor in use, should be checked every 60,000 to 100,000 miles, and if necessary, replaced. In almost every state performing emission tests, a worn-out oxygen sensor will prevent passing an emissions inspection.

Other Tune-up TipsFor optimum fuel economy and longest engine life, auto manufacturers recommend changing the oil and filter at 3,000-mile intervals. If the oil on the dipstick appears dark and burnt before the 3,000-mile interval, as may be the case with frequent towing, installation of an oil cooler could be in order. If the automatic transmission fluid turns from pink to tan before the recommended change interval, a transmission cooler may be needed to prevent transmission failure.

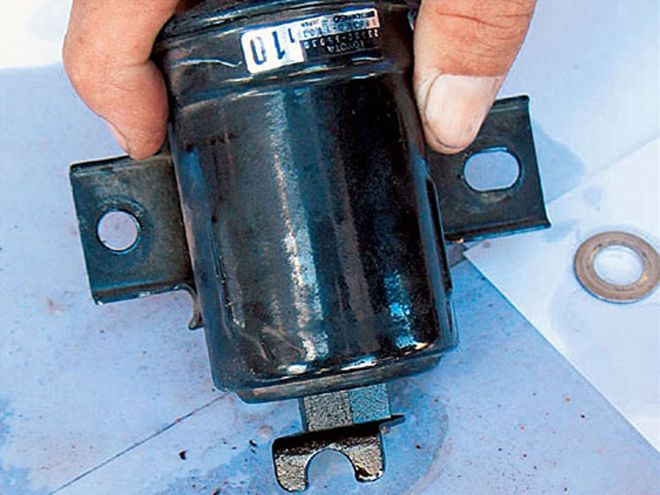

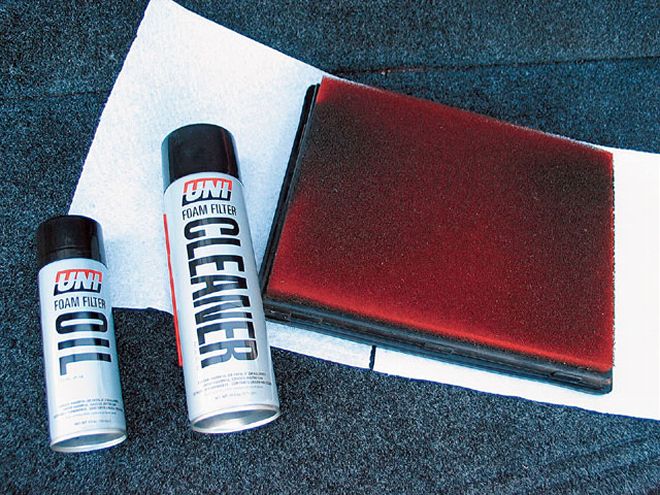

A clean air filter is important for a free-breathing engine, and should be replaced more frequently if a vehicle is used under dusty, severe conditions. Also, even if the engine is running fine, consider a new fuel filter at the recommended replacement interval for spark plugs and plug wires - that is, if it's not a major undertaking to replace it.

It shouldn't even have to be said, but maintaining proper air pressure in the tires will help to reduce rolling resistance, improve fuel economy, improve safe handling, and improve driving pleasure. Make sure those tires are always inflated to manufacturer's specifications.

| bosch Auto Parts Tune Up Basics engine

With gas prices reaching record highs, the fuel-saving benefits, as well as performance improvements, from a much-needed periodic tune-up have never been more pronounced. However, in today's automotive world of computers, converters, environmental regulations, and rapidly changing technology, exactly what is a tune-up anyway?

Many of us remember those wonderful days when a tune-up meant replacing the spark plugs, plug wires, points, rotor, and maybe the distributor cap, and checking the timing and kicking the tires. For many Sport Truck readers who are tooling around in "seasoned" vehicles, this still holds true. For most of us, however, the points, condenser, and rotor are gone forever, and you won't find a bolt to let you adjust the timing if you look all day.

| bosch Auto Parts Tune Up Basics engine

With gas prices reaching record highs, the fuel-saving benefits, as well as performance improvements, from a much-needed periodic tune-up have never been more pronounced. However, in today's automotive world of computers, converters, environmental regulations, and rapidly changing technology, exactly what is a tune-up anyway?

Many of us remember those wonderful days when a tune-up meant replacing the spark plugs, plug wires, points, rotor, and maybe the distributor cap, and checking the timing and kicking the tires. For many Sport Truck readers who are tooling around in "seasoned" vehicles, this still holds true. For most of us, however, the points, condenser, and rotor are gone forever, and you won't find a bolt to let you adjust the timing if you look all day.

| bosch Auto Parts Tune Up Basics bosch Auto Parts

Today, a tune-up normally means:

| bosch Auto Parts Tune Up Basics bosch Auto Parts

Today, a tune-up normally means: | bosch Auto Parts Tune Up Basics spark Plugs

Reading The Plugs

| bosch Auto Parts Tune Up Basics spark Plugs

Reading The Plugs | bosch Auto Parts Tune Up Basics bosch Premium Wire Set

New Plug Wires Assure Spark

| bosch Auto Parts Tune Up Basics bosch Premium Wire Set

New Plug Wires Assure Spark