Our goal, on the other hand, is an engine that produces its power down low, where we can use it every day. We expect this engine to be strong off-idle and produce peak power around 5,500 rpm, which is the range where most street motors perform. Although many magazine buildups stress top-end horsepower, our goal is to maximize torque. Torque is what gets you moving from the stoplight, and its also the ultimate determiner of horsepower. After all, horsepower is just rpm times torque divided by 5,252, and as one engine builder told us, If you give me torque and you take horsepower, Ill beat you every time.

The keys to achieving our goals are good machine work, reasonable compression, and the selection of parts that will work together to produce power.

The biggest advantage to putting a crankshaft from a Chevy 400 into a 350 block to produce 383 cubic inches is that more displacement equals more power. Also, the longer crank throw produces more downward thrust, which translates into torque. And torque is what were after, especially in a truck.

Although a 383 can still be built using a stock GM 400 crank with ground-down main journals, the popularity of this combination has resulted in the availability of new 3.75-inch crankshafts manufactured to fit in a standard 350 block. We opted to go this route, and we further simplified the parts-selection process by ordering an internally balanced 383 rotating assembly from Racing Head Service. The RHS kit comes complete with a new cast-iron stroker crank, cast hypereutectic pistons, reconditioned 350 rods, moly rings, and a new flexplate, as well as camshaft, rod, and main bearings. We also ordered a Comp Cams Xtreme Energy camshaft and lifter set to fill out our short-block assembly. The bumpstick recommended by the experts at RHS specs out at 212/218 degrees of duration at 0.050 lift with 110-degree lobe centers and 0.447/0.454 lift on the intake and exhaust. This profile should produce gobs of torque between 1,000 and 5,200 rpm, making it ideal for our purposes.

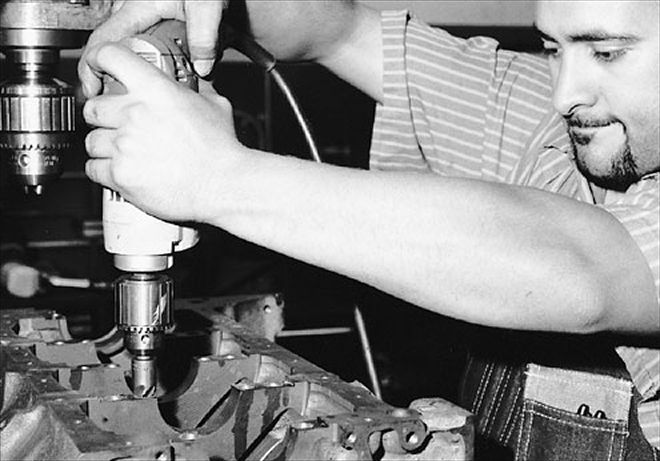

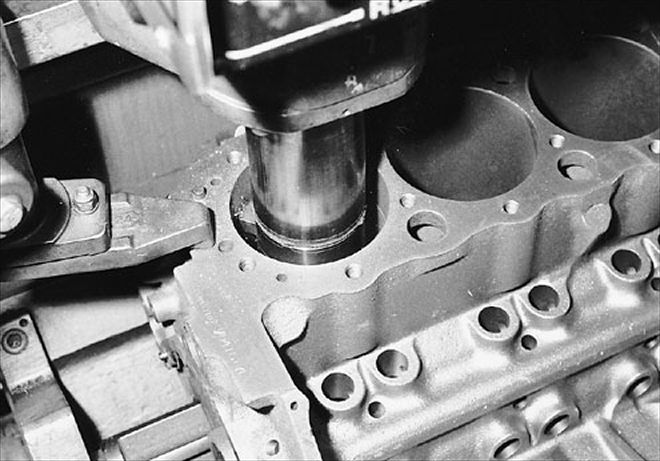

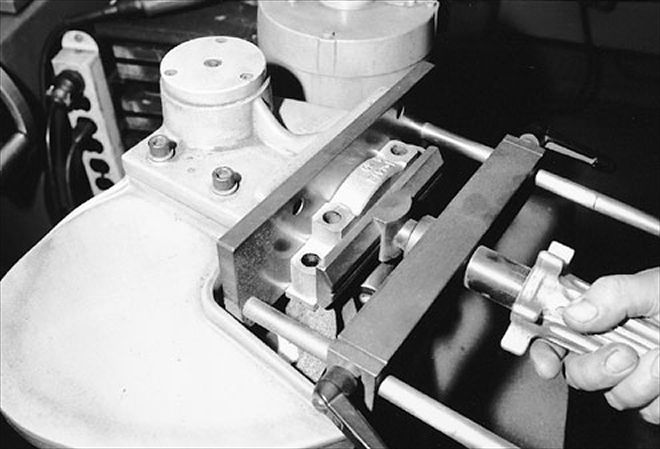

The next major decision we had to make was selecting a set of cylinder heads. Since one of the heads that came with our junkyard core was cracked, we were facing a pretty steep machine-shop bill had we had opted to rebuild them. Rather than invest a bunch of money in junkyard heads, we decided to go with aftermarket heads. The cast-iron World Products S/R Torquers that we chose are generally regarded as one of the best deals going in aftermarket cylinder heads. For about the same out-of-pocket cost of a good head rebuild, you get brand-new castings with better flow characteristics than any stock GM small-block cylinder head, and they come assembled with 2.02-inch intake/ 1.6-inch exhaust Manley valves, new guides, and valvesprings and retainers. If you spend any time investigating the cost of a quality rebuild, you’ll find that the World heads, priced at around $700 per pair assembled, are a deal that’s hard to beat. Rather than reuse our junkyard parts, we completed the valvetrain with a set of reasonably-priced Comp Cams Magnum roller rocker arms and new pushrods.Then we called Summit Racing Equipment to order all the other necessary items to assemble the long block, such as a gasket set, freeze plugs, an oil pump, an oil pan, a timing set, and valve covers. We plan to top the engine off with a Holley dual-plane Dominator intake manifold and a 750-cfm, vacuum-secondary four-barrel carb. With all the parts gathered, we headed up to Jim Grubbs Motorsports in Valencia, California, to have our block machined. The importance of a knowledgeable machine shop to the success of an engine buildup cannot be overstated. Not only is good block prep critical to power production and engine life, the experts at Jim Grubbs Motorsports gave us tons of tips and insight into the right way to build an engine.

Follow along as the crew at JGM whips our block into shape.