| torque Converter Tech breakdown

In today's diesel trucks, automatics are the transmissions of choice, which means torque converters are a factor. With Chevy, Dodge, and Ford all offering more than 600 lb-ft of torque, converters must be up to the task. We'll explain how stock converters work, how aftermarket converters are different, and why you'll most likely need one if you plan on modifying your vehicle.

The easiest way to describe a torque converter is as a fluid coupler. Since there isn't a conventional clutch on an automatic transmission, some way must be devised to let the engine slip so the vehicle doesn't stop running if the vehicle slows to a stop. This is accomplished through a torque converter, which is a device that uses transmission fluid and a turbine-fan arrangement to create enough force to propel the vehicle yet slip enough to let the engine idle while in gear.

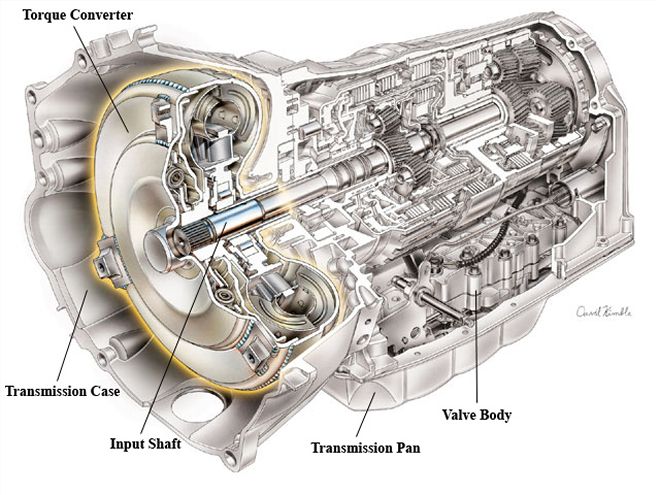

| Cutaway Of A ConverterAutomatic transmissions rely on a fluid coupling, known as a torque converter, to transmit power from the engine to the transmission.

The easiest way to visualize how a torque converter works is to think of two regular house fans that you can plug into the wall to keep cool. If you have a couple of fans around, you can actually try this experiment. Take the two fans and point them at each other, leaving one off while turning the other on. The air from the first fan will start to turn the second, even though there is no power to it. Turn up the power on the primary fan, and the second will spin faster-slow it way down, and the secondary fan will stop. This is how a torque converter works, using transmission fluid instead of air.

One big problem facing diesel torque converters is the immense amount of torque that diesel engines produce. Torque converters combined with gas engines, even in high-performance applications, rarely have to deal with more than 400 lb-ft of torque. In diesel applications, at least 600 lb-ft of torque is the norm, and modified diesel engines can easily make 800 lb-ft of torque. To combat diesels' torque and their limited rpm range, lock-up torque converters are used. With lock-up converters, one (or a series of) hydraulically activated clutch is used to lock the two sides together, effectively connecting the engine directly to the transmission. This eliminates converter slippage and results in more power to the rear wheels, as well as better fuel mileage.

| torque Converter Tech front Back Cover

To understand how a torque converter works, we looked at one from an Allison transmission that has been cut in half, starting with the side facing the transmission.

This is the view from the transmission, and it's where the input shaft slides in. The front and back covers of a torque converter are press-fitted and welded together. If the weld is broken, we can gain access to the inside of the converter.

| torque Converter Tech stator

With the back cover off, the first thing we see is the stator from the torque converter. The purpose of the stator is to redirect the fluid back to the pump after it exits the turbine so that a high level of efficiency is maintained.

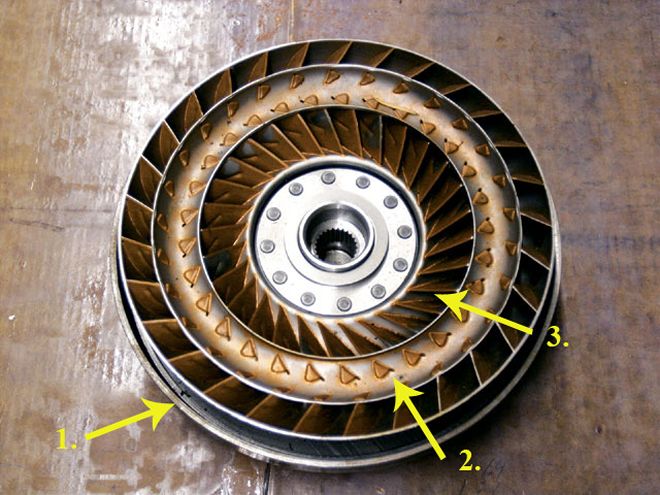

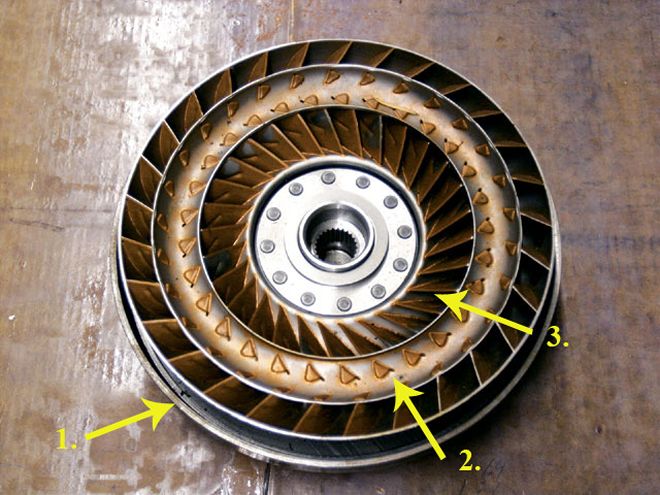

| torque Converter Tech turbine Pump

This is the most important illustration when it comes to understanding how a torque converter works. The rear cover that is facing the transmission looks similar to this, but the inner vanes are much straighter. When fluid enters that portion of the converter, it is flung out to the sides (kind of like how a washing machine washes clothes). The fluid that is on the outside of the converter's pump side enters the second half of the converter (known as the turbine), which is seen here. Fluid enters the turbine (arrow 1) and enters a valley (arrow 2) where it must reverse its flow as it exits (arrow 3). This reversal in flow is actually what turns the turbine and powers the vehicle.

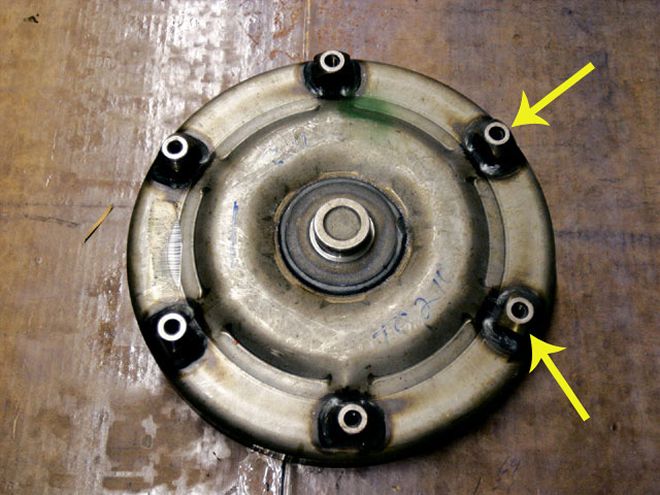

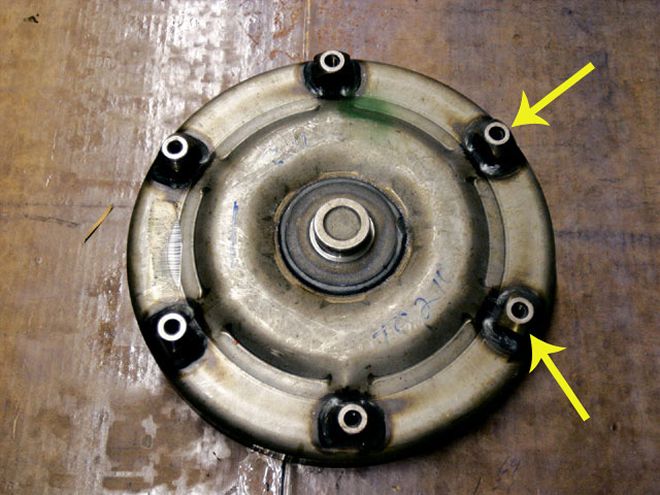

| torque Converter Tech engine Side Converter

When flipping the front cover of the converter over, we can see the side that connects to the engine. A common problem with converters on modified trucks is that they will actually rip the lugs off the converter (arrows). To solve this problem, many aftermarket converters have a solid face with threads for the flexplate tapped into the front cover so this can't happen.

| torque Converter Tech breakdown

In today's diesel trucks, automatics are the transmissions of choice, which means torque converters are a factor. With Chevy, Dodge, and Ford all offering more than 600 lb-ft of torque, converters must be up to the task. We'll explain how stock converters work, how aftermarket converters are different, and why you'll most likely need one if you plan on modifying your vehicle.

The easiest way to describe a torque converter is as a fluid coupler. Since there isn't a conventional clutch on an automatic transmission, some way must be devised to let the engine slip so the vehicle doesn't stop running if the vehicle slows to a stop. This is accomplished through a torque converter, which is a device that uses transmission fluid and a turbine-fan arrangement to create enough force to propel the vehicle yet slip enough to let the engine idle while in gear.

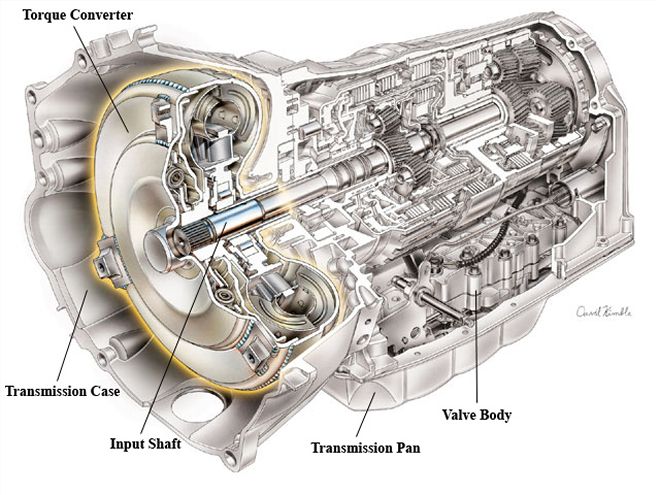

| torque Converter Tech breakdown

In today's diesel trucks, automatics are the transmissions of choice, which means torque converters are a factor. With Chevy, Dodge, and Ford all offering more than 600 lb-ft of torque, converters must be up to the task. We'll explain how stock converters work, how aftermarket converters are different, and why you'll most likely need one if you plan on modifying your vehicle.

The easiest way to describe a torque converter is as a fluid coupler. Since there isn't a conventional clutch on an automatic transmission, some way must be devised to let the engine slip so the vehicle doesn't stop running if the vehicle slows to a stop. This is accomplished through a torque converter, which is a device that uses transmission fluid and a turbine-fan arrangement to create enough force to propel the vehicle yet slip enough to let the engine idle while in gear.

| Cutaway Of A ConverterAutomatic transmissions rely on a fluid coupling, known as a torque converter, to transmit power from the engine to the transmission.

The easiest way to visualize how a torque converter works is to think of two regular house fans that you can plug into the wall to keep cool. If you have a couple of fans around, you can actually try this experiment. Take the two fans and point them at each other, leaving one off while turning the other on. The air from the first fan will start to turn the second, even though there is no power to it. Turn up the power on the primary fan, and the second will spin faster-slow it way down, and the secondary fan will stop. This is how a torque converter works, using transmission fluid instead of air.

One big problem facing diesel torque converters is the immense amount of torque that diesel engines produce. Torque converters combined with gas engines, even in high-performance applications, rarely have to deal with more than 400 lb-ft of torque. In diesel applications, at least 600 lb-ft of torque is the norm, and modified diesel engines can easily make 800 lb-ft of torque. To combat diesels' torque and their limited rpm range, lock-up torque converters are used. With lock-up converters, one (or a series of) hydraulically activated clutch is used to lock the two sides together, effectively connecting the engine directly to the transmission. This eliminates converter slippage and results in more power to the rear wheels, as well as better fuel mileage.

| Cutaway Of A ConverterAutomatic transmissions rely on a fluid coupling, known as a torque converter, to transmit power from the engine to the transmission.

The easiest way to visualize how a torque converter works is to think of two regular house fans that you can plug into the wall to keep cool. If you have a couple of fans around, you can actually try this experiment. Take the two fans and point them at each other, leaving one off while turning the other on. The air from the first fan will start to turn the second, even though there is no power to it. Turn up the power on the primary fan, and the second will spin faster-slow it way down, and the secondary fan will stop. This is how a torque converter works, using transmission fluid instead of air.

One big problem facing diesel torque converters is the immense amount of torque that diesel engines produce. Torque converters combined with gas engines, even in high-performance applications, rarely have to deal with more than 400 lb-ft of torque. In diesel applications, at least 600 lb-ft of torque is the norm, and modified diesel engines can easily make 800 lb-ft of torque. To combat diesels' torque and their limited rpm range, lock-up torque converters are used. With lock-up converters, one (or a series of) hydraulically activated clutch is used to lock the two sides together, effectively connecting the engine directly to the transmission. This eliminates converter slippage and results in more power to the rear wheels, as well as better fuel mileage.

| torque Converter Tech front Back Cover

To understand how a torque converter works, we looked at one from an Allison transmission that has been cut in half, starting with the side facing the transmission.

This is the view from the transmission, and it's where the input shaft slides in. The front and back covers of a torque converter are press-fitted and welded together. If the weld is broken, we can gain access to the inside of the converter.

| torque Converter Tech front Back Cover

To understand how a torque converter works, we looked at one from an Allison transmission that has been cut in half, starting with the side facing the transmission.

This is the view from the transmission, and it's where the input shaft slides in. The front and back covers of a torque converter are press-fitted and welded together. If the weld is broken, we can gain access to the inside of the converter.

| torque Converter Tech stator

With the back cover off, the first thing we see is the stator from the torque converter. The purpose of the stator is to redirect the fluid back to the pump after it exits the turbine so that a high level of efficiency is maintained.

| torque Converter Tech stator

With the back cover off, the first thing we see is the stator from the torque converter. The purpose of the stator is to redirect the fluid back to the pump after it exits the turbine so that a high level of efficiency is maintained.  | torque Converter Tech turbine Pump

This is the most important illustration when it comes to understanding how a torque converter works. The rear cover that is facing the transmission looks similar to this, but the inner vanes are much straighter. When fluid enters that portion of the converter, it is flung out to the sides (kind of like how a washing machine washes clothes). The fluid that is on the outside of the converter's pump side enters the second half of the converter (known as the turbine), which is seen here. Fluid enters the turbine (arrow 1) and enters a valley (arrow 2) where it must reverse its flow as it exits (arrow 3). This reversal in flow is actually what turns the turbine and powers the vehicle.

| torque Converter Tech turbine Pump

This is the most important illustration when it comes to understanding how a torque converter works. The rear cover that is facing the transmission looks similar to this, but the inner vanes are much straighter. When fluid enters that portion of the converter, it is flung out to the sides (kind of like how a washing machine washes clothes). The fluid that is on the outside of the converter's pump side enters the second half of the converter (known as the turbine), which is seen here. Fluid enters the turbine (arrow 1) and enters a valley (arrow 2) where it must reverse its flow as it exits (arrow 3). This reversal in flow is actually what turns the turbine and powers the vehicle.

| torque Converter Tech engine Side Converter

When flipping the front cover of the converter over, we can see the side that connects to the engine. A common problem with converters on modified trucks is that they will actually rip the lugs off the converter (arrows). To solve this problem, many aftermarket converters have a solid face with threads for the flexplate tapped into the front cover so this can't happen.

| torque Converter Tech engine Side Converter

When flipping the front cover of the converter over, we can see the side that connects to the engine. A common problem with converters on modified trucks is that they will actually rip the lugs off the converter (arrows). To solve this problem, many aftermarket converters have a solid face with threads for the flexplate tapped into the front cover so this can't happen.