The Basics of MIG Welding - You Can Do It

| mig Welding you Can Do It

If you've never fabricated anything for your truck but would like to, you can learn the most basic skill necessary, MIG welding, to build most anything for your ride. This article will give you the basic knowledge to safely operate a MIG welder. Once you have the basics down, the sky is the limit - and so is the level of performance of your truck.

Gas Metal Arc Welding is commonly referred to as MIG welding. The MIG welding process was developed in the late 1940s as an alternative to Gas Tungsten Arc Welding, which uses a nonconsumable tungsten electrode and is a much slower welding process. MIG welding is preferred in many applications because it is easy to learn, has a high deposition rate, and creates minimal weld slag.

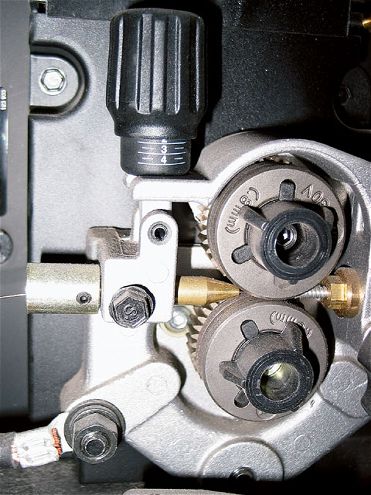

A wire-feed MIG welder outfit consists of the welder itself and several "consumable" items. These consumables include the electrode, welding wire, and shielding gas. A MIG welder is capable of welding ferrous metals such as steel, aluminum, and stainless steel, depending on what type of shielding gas you use and the diameter and type of the weld wire. Since our trucks are built from steel, we'll concentrate our efforts toward making good welds on steel from sheetmetal up to 3/16-inch steel plate.

A MIG welder welds steel together by heating the metals with an electric arc. The arc is generated between the electrode in the welding gun and the metalwork piece. This arc is shielded from contaminants in the atmosphere by the shielding gas. The most common shielding gas that is readily available at welding supply houses is a mixture of 75 percent argon and 25 percent CO2. This mix helps produce welds with little slag and excellent penetration. There is a multitude of electrode-wire types available for welding different types of metal. The wire we'll use in conjunction with the shielding gas will have a steel core with a copper coating and a diameter of 0.035 inch. This wire will be suitable for welding steel with a thickness between 1/6 and 3/8 inch. Should we ever decide to weld sheetmetal with a smaller thickness, we can switch electrodes in our welding gun and then switch to a smaller diameter wire, such as 0.023 inch.

MIG welding is one of the easiest welding processes to learn as well as the most inexpensive. A basic MIG-welding outfit can be purchased for less than $500 and requires only a small amount of time to competently operate. Here is a look at a typical MIG welding setup as well as what a good weld looks like and why a bad weld occurs.

| mig Welding you Can Do It

If you've never fabricated anything for your truck but would like to, you can learn the most basic skill necessary, MIG welding, to build most anything for your ride. This article will give you the basic knowledge to safely operate a MIG welder. Once you have the basics down, the sky is the limit - and so is the level of performance of your truck.

Gas Metal Arc Welding is commonly referred to as MIG welding. The MIG welding process was developed in the late 1940s as an alternative to Gas Tungsten Arc Welding, which uses a nonconsumable tungsten electrode and is a much slower welding process. MIG welding is preferred in many applications because it is easy to learn, has a high deposition rate, and creates minimal weld slag.

A wire-feed MIG welder outfit consists of the welder itself and several "consumable" items. These consumables include the electrode, welding wire, and shielding gas. A MIG welder is capable of welding ferrous metals such as steel, aluminum, and stainless steel, depending on what type of shielding gas you use and the diameter and type of the weld wire. Since our trucks are built from steel, we'll concentrate our efforts toward making good welds on steel from sheetmetal up to 3/16-inch steel plate.

A MIG welder welds steel together by heating the metals with an electric arc. The arc is generated between the electrode in the welding gun and the metalwork piece. This arc is shielded from contaminants in the atmosphere by the shielding gas. The most common shielding gas that is readily available at welding supply houses is a mixture of 75 percent argon and 25 percent CO2. This mix helps produce welds with little slag and excellent penetration. There is a multitude of electrode-wire types available for welding different types of metal. The wire we'll use in conjunction with the shielding gas will have a steel core with a copper coating and a diameter of 0.035 inch. This wire will be suitable for welding steel with a thickness between 1/6 and 3/8 inch. Should we ever decide to weld sheetmetal with a smaller thickness, we can switch electrodes in our welding gun and then switch to a smaller diameter wire, such as 0.023 inch.

MIG welding is one of the easiest welding processes to learn as well as the most inexpensive. A basic MIG-welding outfit can be purchased for less than $500 and requires only a small amount of time to competently operate. Here is a look at a typical MIG welding setup as well as what a good weld looks like and why a bad weld occurs.

| mig Welding you Can Do It

If you've never fabricated anything for your truck but would like to, you can learn the most basic skill necessary, MIG welding, to build most anything for your ride. This article will give you the basic knowledge to safely operate a MIG welder. Once you have the basics down, the sky is the limit - and so is the level of performance of your truck.

Gas Metal Arc Welding is commonly referred to as MIG welding. The MIG welding process was developed in the late 1940s as an alternative to Gas Tungsten Arc Welding, which uses a nonconsumable tungsten electrode and is a much slower welding process. MIG welding is preferred in many applications because it is easy to learn, has a high deposition rate, and creates minimal weld slag.

A wire-feed MIG welder outfit consists of the welder itself and several "consumable" items. These consumables include the electrode, welding wire, and shielding gas. A MIG welder is capable of welding ferrous metals such as steel, aluminum, and stainless steel, depending on what type of shielding gas you use and the diameter and type of the weld wire. Since our trucks are built from steel, we'll concentrate our efforts toward making good welds on steel from sheetmetal up to 3/16-inch steel plate.

A MIG welder welds steel together by heating the metals with an electric arc. The arc is generated between the electrode in the welding gun and the metalwork piece. This arc is shielded from contaminants in the atmosphere by the shielding gas. The most common shielding gas that is readily available at welding supply houses is a mixture of 75 percent argon and 25 percent CO2. This mix helps produce welds with little slag and excellent penetration. There is a multitude of electrode-wire types available for welding different types of metal. The wire we'll use in conjunction with the shielding gas will have a steel core with a copper coating and a diameter of 0.035 inch. This wire will be suitable for welding steel with a thickness between 1/6 and 3/8 inch. Should we ever decide to weld sheetmetal with a smaller thickness, we can switch electrodes in our welding gun and then switch to a smaller diameter wire, such as 0.023 inch.

MIG welding is one of the easiest welding processes to learn as well as the most inexpensive. A basic MIG-welding outfit can be purchased for less than $500 and requires only a small amount of time to competently operate. Here is a look at a typical MIG welding setup as well as what a good weld looks like and why a bad weld occurs.