Auto Meter has stepped it up another notch with the release of the Nexus system of gauges. The company definitely lives up to its motto of "Next Generation Instruments," as the gauges in the Nexus lineup feature an integrated approach that uses a master control unit, electronic sending units, and displays. Simply put, this series of gauges is amazing. Why should you consider them? What other gauges on the market integrate modern-day, automotive-style CAN electronics (more below), maintain high accuracy and reliability, and provide utmost ease of installation? Take a look at the following features offered by the Nexus gauges:

| Ready for the install with all the auto Meter parts.

Powered by digital microprocessor-controlled rugged stepper motor drives • Seven LED illumination colors • Programmable warnings • Signal Playpack • Peaks • Built in data-logging on SD flash memory for PC downloading • Expandable to accept more gauges in the future

Unique in the aftermarket automotive instrumentation world, the Nexus gauges utilize a proprietary digital communications network between gauges. Auto Meter calls this its n1.0 Network System, which is based on controller area network (CAN) technology. CAN is a broadcast differential serial bus standard, originally developed by Robert Bosch for connecting electronic control units (ECUs) back in the '80s. CAN was designed specifically for automotive applications, in which noisy environments can cause signal degradation. This technology allows single modular cable connection for easy installation. In other words, you can daisy-chain the gauges from one to the next, which makes installation, quite literally, a snap!

Moving on to the gauges themselves, there are two main components: the 2 1/16-inch gauge display (which now functions as an analog readout), and a gauge sending unit, both of which plug into the central control unit. First, the gauges have a 270-degree sweep, quite similar to their mechanical gauges-but with a twist. The gauges utilize a precision-stepper motor that drives the needle, similar to what you would find in Auto Meter's short-sweep electric gauges. Why a stepper motor? The advantage is that it provides repeatability and accuracy that exceeds a mechanical gauge. With a mechanical gauge, you're fighting the friction and wear of the moving parts inside, which, over time, may change the readout of the gauge. The user-adjustable seven-color gauge illumination can be used to match the factory dash illumination-blue, white, red, orange, green, yellow, and purple. Can't decide which color to use? There's even a built-in feature that, when selected, causes the illumination color to crossfade from one color to the next-very trick.

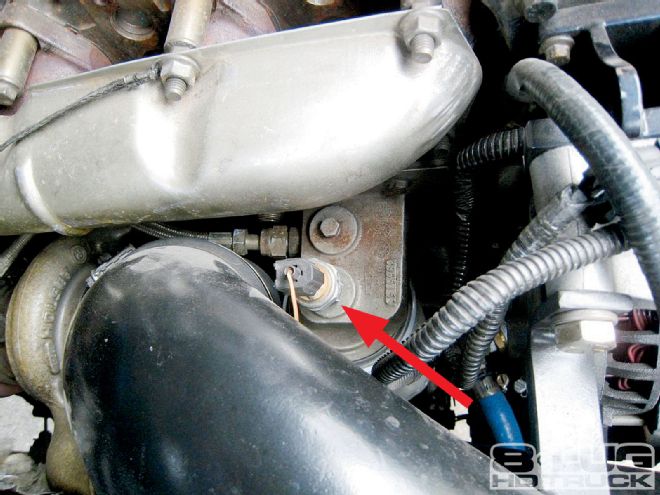

The sending units are track-tested and race-proven. The Nexus system uses precision senders to keep hazardous fluids out of the driver compartment and perform gauge calibration and sensor diagnostics at power-up for extreme accuracy-every time. And that's what makes the Nexus line so unique-all the engine characteristics are measured with these senders under the hood, and the signals are sent directly to the sensor module. From there, the signals are processed and then broadcast on the CAN bus line to the appropriate gauges. This also makes for an easy gauge installation, as you no longer have to run pressure tubes and wires directly to the gauges. Additionally, the Nexus system uses the N1.0 network to data-log all the channels, which enables the user to view the information on a PC. All this is stored on a secure digital (SD) card accessed on the remote control.

The Nexus gauges are expandable as well. In the event that you want to add more gauges, the following are available:

Oil Pressure • Fuel Pressure • Vacuum/Boost Pressure • Boost • Oil Temperature • Water Temperature • Nitrous Pressure • Exhaust Gas Temperature • Fuel Level • Fuel Pressure • Transmission Temperature • Voltmeter • Water Temperature

The project truck shown here, Project Rockstar, recently swapped out a 7.3L Power Stroke for a 5.9L Cummins high-pressure common-rail. To go with the engine overhaul, a gauge overhaul was definitely required. In a diesel truck application, the three typical gauges you'll find are: boost, pyrometer, and transmission temperature. The Rockstar has a manual transmission, thus a transmission temperature gauge is not required. The Auto Meter Quad Pod A-pillar gauge mount was reused in this application, so in addition to the pyrometer and boost gauge, two more mounting locations were available-now occupied by the oil pressure gauge and fuel pressure gauge. Project Rockstar's original Power Stroke motor has been replaced by a high-output Cummins ISBe common-rail motor from an '03 Dodge Ram. Both gauge values are critical information to monitor on a modified Cummins diesel.

This installation will cover an upgrade of gauges, going from a set of Auto Meter Ultra-Lites to its premier Nexus gauges. For a detailed installation of gauges on a new Ford Super Duty, see the write-up of Project JAKD at: truckblog.com/1312-howto_install_auto_meter_gauges_in_project_jakd

The final word? Combining rugged, automotive-style electronics and laboratory precision measurements is the perfect match for Project Rockstar. The gauges have worked flawlessly and have impressed numerous people, leaving them slack-jawed and wanting to find out where they can get their own set. Auto Meter has definitely raised the bar in performance automotive instrumentation.