For the second installment on our ’08 F-250 drag truck, we got to work bulletproofing the 6.4L Power Stroke. First things first: A full-on teardown process took place, and similar to what we did during our stock 5R110 transmission’s autopsy (July, ’13), we examined the factory pieces for wear and tear. Upon disassembly of the 60,000-mile engine, we noticed the exhaust valves had kissed the pistons a time or two. The slight piston-to-valve contact likely occurred when we were spraying the engine with nitrous. With the factory, non-wastegated 52mm/65mm compound turbocharger arrangement intact, this led to high drive pressure and forced the exhaust valves to creep open when they weren’t supposed to. Everything else inside the 6.4L mill looked to be in good shape.

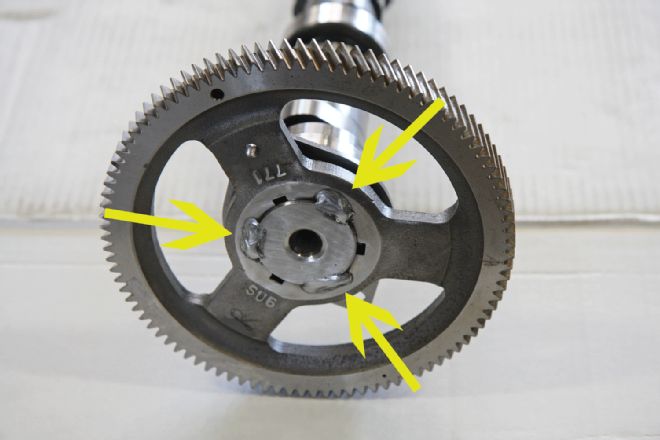

To prep the engine for 900hp duty, a mix of aftermarket upgrades and fresh OE components made it into the build. Forged connecting rods, fly-cut and coated International pistons, and a reground cam with increased lift and duration were gifts from the aftermarket, while each rotating surface was fitted with a factory-spec bearing. As for the rods, even though we’ve seen the stock units handle more than 1,000 hp, we decided it was better to play it safe. When it’s all said and done, we want a reliable, mid-10-second truck—reason enough to make the bottom end as indestructible as possible.

The No-Frills Build Continues

Part 3: New lifters, head studs, valvesprings, and pushrods

Part 4: Dual K16 high-pressure fuel pumps, 200hp nozzles, fuel supply system

Part 5: T4 single turbocharger mount, S475, up-pipes, and exhaust manifolds

Part 6: Dyno tuning and track testing