One of the build requirements of the Project KR Ford Super Duty was the King Ranch package. This trim level offered what we wanted from the factory in regard to seating, body color, and other amenities, but the King Ranch also gave us some items we would want to change. One of the items not on the wish list was the factory running boards. They fit great and have a function, but for our build, they had to go. We wanted a clean bodyside, free of visual exterior steps.

| 01. Everything was laid out on the floor prior to the install: two boards, four linkage arms, one controller, two motors, and one wiring harness.

Project KR’s theme is “King of the Road,” and to accomplish that task, we are using premier quality parts, bringing together the top manufacturers in the automotive industry. Ford Motor Company, BFGoodrich, Centerline, Eaton, Rancho Suspension, Edge, AFE, BASF, Superior Gear, Penhall Fabrication, and Warn Industries are a few of the manufacturers involved with Project KR.

When it came time to choose steps for our project truck, we went with the PowerStep from AMP Research in Irvine, California. Horst Leitner, founder of AMP Research, has been an innovator of products and vehicles for years. His ATK motorcycles and AMP mountain bikes took us to new levels of design. So when he entered the automotive world with his Bed Extender, PowerStep, and other folding steps, he again made his mark with innovation. The quality he puts in all his products is what is so impressive. Everything is made in America, and he uses the finest materials so they will last. It’s like having the aerospace mindset in the automotive industry—and that’s a winning combination for a person who understands and appreciates it.

| 02. With the truck in place, the crew at Granger’s Classic Auto Body removed the factory running boards.

Now, about the AMP PowerStep: It installs right where the factory running boards attach to the cab, utilizing the same mounting points. When not in use, the PowerSteps retract and are hidden under the cab. The running board is activated by opening the door, and drops into place, allowing easy access to the interior. Another nice feature of the power running board is that when in the down position, it is approximately 3 inches lower than the factory running board—a great feature for our lifted Super Duty. In the retracted position they are not visible, leaving the exterior of the truck lines clean. In fact, to see the steps on our truck, you actually have to get below the floor cab line and look up. The step boards are made from extruded 6063 aluminum, with a textured, powdercoat finish. The linkage is a die-cast, U.S.-certified, aluminum-alloy, anodized-black that’s Teflon-coated to military specs to prevent corrosion. The pivot pins and bearings are made of stainless steel, generating a load capacity of 600 pounds for each step.

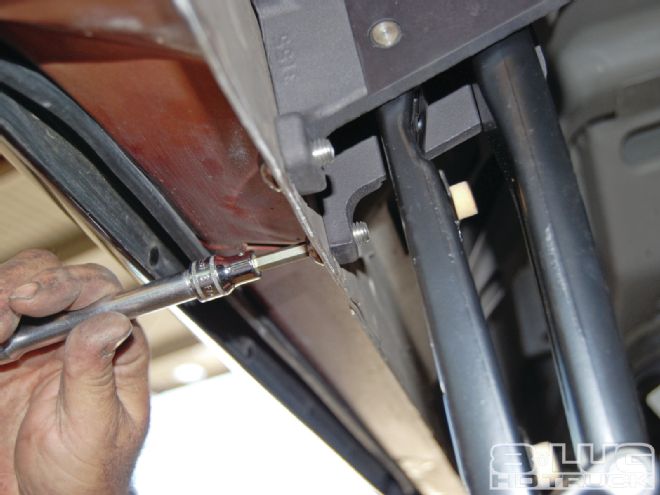

| 12. This photo shows the linkage in place and the emergency brake cable moved up and out of the way. The steps are attached to the linkage. The step and the linkage were locked in place and secured with fasteners supplied by AMP.

“Project KR’s theme is “King of the Road,” and to accomplish that task, we are using premier quality parts, bringing together the top manufacturers in the automotive industry.”

For Project KR, we needed a quality shop to do the installation of the steps. For that, we enlisted Fidel Acosta and his shop, Granger’s Classic Auto Body, in Reseda, California. Since the install, we have been impressed by how flawlessly these quality steps have performed. On the Super Duty the fit is excellent, offering a solid feel when you step up on the board. When activated, they appear from under the cab in a smooth, solid, quick action. We’ve enjoyed watching first-time passengers give the “How am I going to get in?” look. And when the door opens, a little smile hits their faces.

Step on up, lets go!