When we took possession of our ’08 Ford F-250, we knew we’d be modifying the axles. From the factory, our Super Duty differentials were standard-fitted with the 3.55 ratio. With the standard axles, we really only have two-wheel drive, and that doesn’t work when you need to get out of a tough situation with limited traction. To be fair, the factory didn’t even offer what we wanted, so it didn’t matter to us how the truck came from the assembly line, since we were going to change it anyway. Eaton Performance Products offers several options for the Ford F-250 4x4, with its Truetrac, Detroit Locker, and ELocker differentials. Each differential has its own strengths, so which one you should choose is based in part on how you use your truck.

The Truetrac is a limited-slip differential that never locks up. It operates by transferring power to the wheel with the most traction, thus helping control the amount of rotation (spin). When both tires spin, the unit will apply power to both tires. This design gives a smooth operation and works well for off-road racing conditions. As you are in and out of the accelerator, the vehicle maintains its course without wandering.

| 2008 Ford F250 Project Kr Part Four super Duty Differentials

Next, we have the ELocker, which operates as a standard or open differential. When the ELocker is engaged with the push of a button, pins inside the unit are energized (causing full lock), which gives the operator full control regarding when and where to lock the differential. Should current to the unit be stopped intentionally (or not), the ELocker will return to a standard or open condition.

Finally, the Detroit Locker is a differential that is locked 100 percent when the vehicle is traveling in a straight line (or if the tires are spinning) and unlocks during a turn for the wheel that is rotating the fastest. This is the most aggressive differential of the group. There is backlash between the drive and the driven teeth—you will feel it and hear it.

| 01. With the truck on a hoist, the front differential oil was drained and the cover was removed. The driveshaft was disconnected from the differential (only) and held up to the frame by a wire.

Starting with the front axle on our Ford, the Dana 60 works great with all of the above traction devices, but for Project KR, it came down to picking between the Truetrac and the ELocker. They each have their strengths and weaknesses, and either differential would work great. Thank you, Eaton.

We decided to go with the ELocker in the front for its versatility—being able to choose when and where to lock has its rewards. There are situations when (for steering purposes) you need to be able to maneuver around (off camber comes to mind). In this situation, the ability to unlock and have an open front and then lock up again is ideal. With the decision for the front made, we moved to the Ford 10.25 rear axle. Again, it was between two differentials: the Truetrac and the Detroit Locker. If you want a transparent feel, the Truetrac is the clear choice. It simply works without any fuss. But the Detroit Locker is our choice. Yes, it is aggressive and you feel it, but it is the strongest. It always works. You can break an axle in your floating housing and still drive home. Get in and get out. From water and mud to snow and rocks—it works, and it works great. In fact, in the late ’60s, the Detroit Locker was a factory option in some Ford cars.

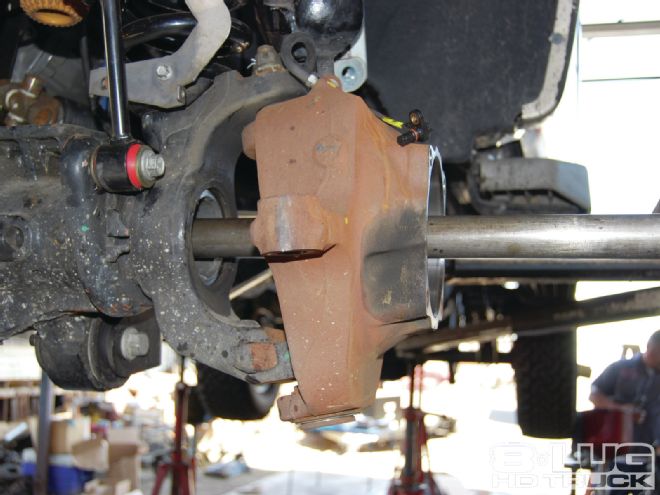

| 02. Ken Conklin removed the brake caliper, rotor, vacuum hoses, and brake sensors. He can now remove the hub and axle. Note that he removed them together.

With the Eaton units chosen, we addressed the gearing ratio. We wanted a ratio that would perform well on the highway and off-road. With our tire diameter range of 35 to 37 inches, we wanted to have the truck stay in the 1,950-rpm range at 65 to 70 mph. We made a call to Superior Axle & Gear in Rancho Cucamonga, California, and the crew recommended a 4.10 ratio to fit our requirements. We went with reverse cut for the inverted front differential and standard cut for the rear. Superior Axle & Gear manufactured both.

For cooling of the differentials (especially for the rear), we went to Mag-Hytec in Van Nuys, California. The Mag-Hytec covers hold more oil and have a service drain and a magnetic oil level inspection rod. The covers are made here in America and the craftsmanship is second to none.

| 18. With the factory ring gear and carrier out, the pinion gear nut was removed. Gabriel has already taken the torque reading from the factory pinion gear, so it can be duplicated when installing the new pinion gear.

When it came time for the installation, one company that stood out was Tri-County Gear in Pomona, California. We talked to owner Jason Bunch, and he explained that his company has the best people in each department. Gabriel Garcia does the gears and differentials, Ken Conklin does the R&R, Mike Montana is the electrical specialist, and Jay Parodi is the parts guy.

| 19. The balancer was removed using a puller. Extra care was taken to avoid damaging the rubber isolator within the balancer.

Review

Once we put a few hundred break-in miles on the gears, we were able to drive more aggressive and get the feel of the differentials. The Detroit Locker feedback is minimal on-highway, but when the engine is on Level 4 of tune (100 hp), you do feel more of the backlash. Most people who have ridden in the truck don’t even notice—you have to point it out.

As for off-road, the combination of the ELocker (front) and Detroit Locker (rear) works great. Crawling up the side of a ridge with loose gravel and having all four tires pulling is a treat. The conditions have less of an effect on the truck getting in and getting out. Something else to remember with locked differentials is that going forward or reversing does not affect their operation. Make no mistake—this is still a big truck when in the backcountry, but now it is a little more agile and secure.

| 20. To ensure the threads didn’t come loose when they were installed in the carrier, red thread lock was used.