1996 Chevy C1500 Project, Part II

In the previous installment of Project Daily Driver, we saw our new three-door 1996 Chevy 1/2-ton undergo a suspension transformation from stock to ground-hugger. Once we had the truck down to a more respectable ride height with all Bell Tech lowering components, our attention turned from the suspension to squeezing some extra ponies out of the stock but all-new-for-1996 Vortec 5000 engine.

Our 5.0L V-8 engine is by no means a slug in stock form. According to the manufacturer, the Vortec 5000 V-8 produces 230 hp at 4,600 rpm and 285 lb-ft of torque at 2,800 rpm. Compare those numbers to the same 5.0L-equipped truck in 1995. The 1995 5.0L engine produced a mere 175 hp at 4,200 rpm and 256 lb-ft of torque at 2,800 rpm. The 1996 Vortec 5000 engine even beat the venerable 1995 5.7L 350ci small-block, which produced 200 hp at 4,000 rpm and only slightly better torque figures of 310 lb-ft. However, being in the magazine business means modifications, and that’s exactly what we decided to do.

On-Board Diagnostics (OBD-II) is another brand-new-for-1996 feature. Even before it was announced that this new electronic system would be standard on all 1996 vehicles, the general population as well as the aftermarket industry was already wondering what kind of engine modifications could be made to OBD-II-equipped trucks. For more information and a really in-depth look at OBD-II, see "OBD-II & You," Sept. 1996.

Next time, we'll turn our lowered truck into the quintessential sport truck with numerous body bolt-ons and modifications. Then, Project Daily Driver will take on the true feeling of a lowered sport truck. However, before we jump ahead of ourselves, let's delve into Phase II.

Phase II

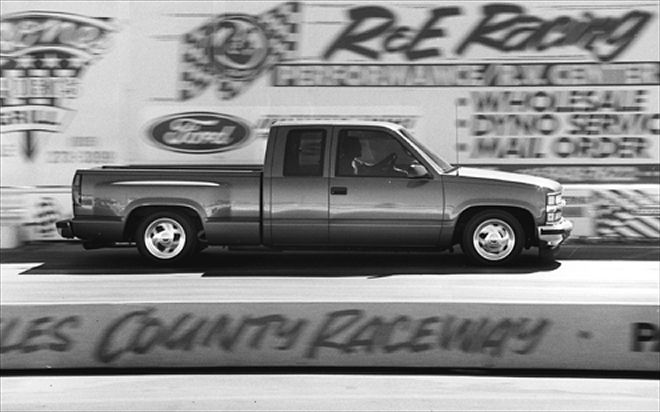

Prior to the suspension installation, we ran a series of baseline tests at nearby Los Angeles County Raceway and, after some coaxing, got the big-boy truck down the track in 18.05 seconds at 75.81 mph (uncorrected) in the quarter-mile--respectable times, but not good enough in our eyes. So began the modification process.

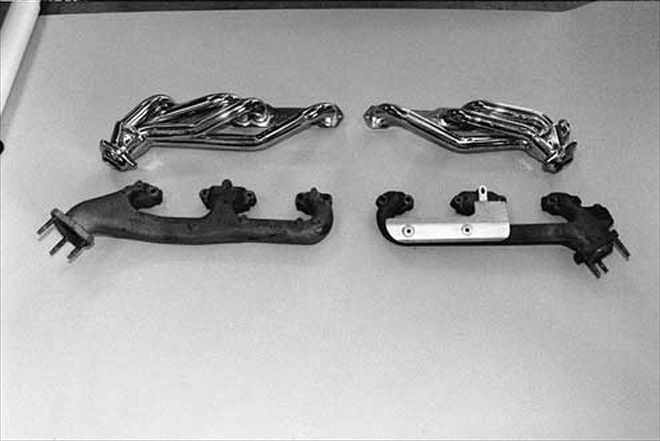

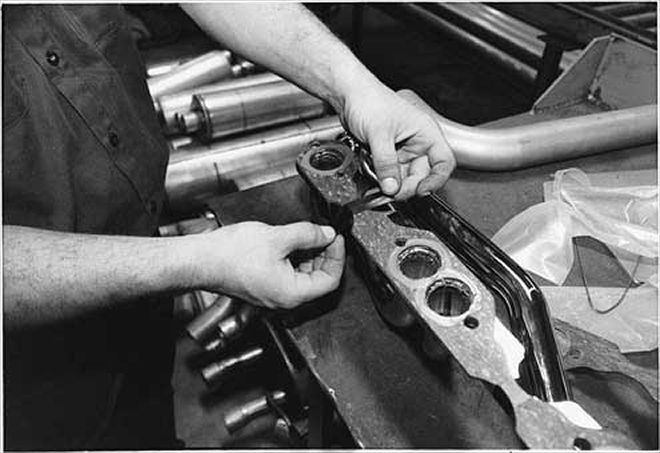

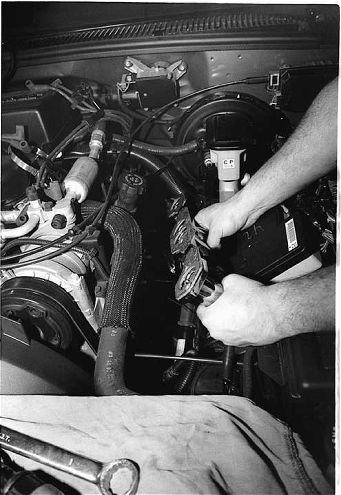

We added many quick and easy bolt-on power products that are 50-state emissions-legal and can be installed by the average truck owner using a variety of handtools. The first modification was to the exhaust system. Gibson Performance Exhaust Systems installed a set of its new shorty headers. Constructed of rugged 14-gauge mandrel-bent tubing, heavy-duty 3/8-inch exhaust flanges, and 3/8-inch collector flanges, these headers are designed to reduce exhaust gas restriction and help dissipate engine heat more rapidly. A unique feature of the shorty headers is that no cutting or welding is required to rehook the exhaust collector to the stock exhaust pipe.

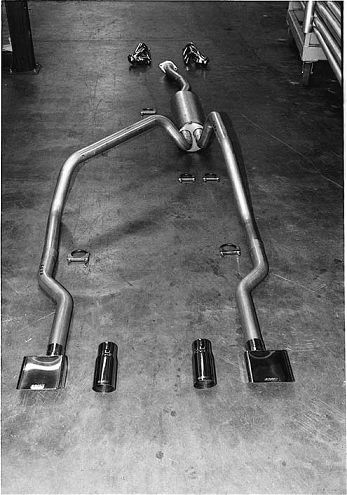

We also added an all-stainless steel free-flowing Gibson after-cat system that includes a new head pipe, free-flow muffler, and tailpipe.

The other engine mods were limited to Hypertech’s new Power Programmer Plus and 160-degree PowerStat thermostat. The Power Programmer Plus simply interfaces with the truck’s Data Link Connector, conveniently located under the dash and to the left of the steering wheel. Once it’s connected, follow the instructions displayed on the screen of the small handheld Hypertech computer. Installing the PowerStat thermostat is a simple remove-and-replace operation. We also installed one of K&N’s new High-Flow cleanable air-filters.