Question

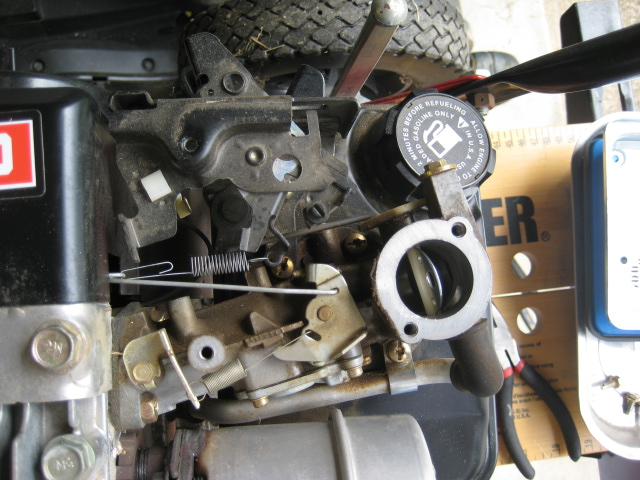

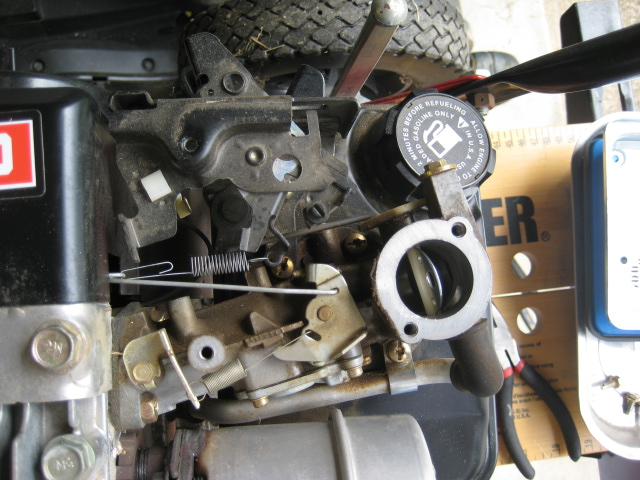

Carb top view before c

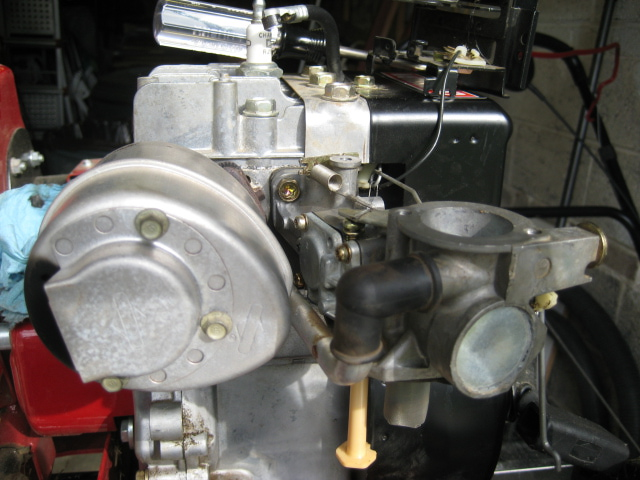

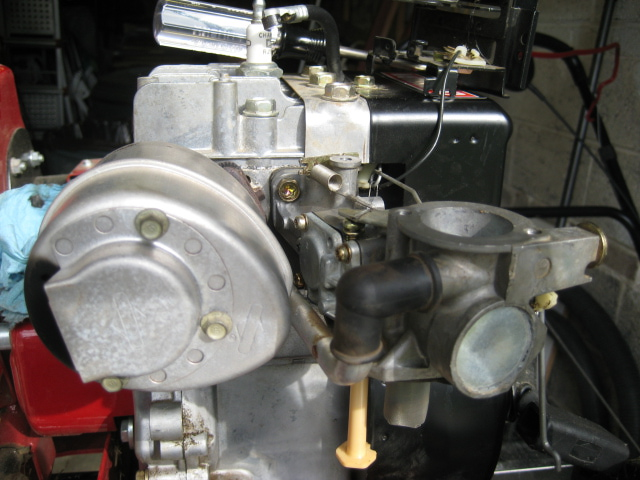

Carb top view before c  View from rear

View from rear

Craftsman 4hp Edger

Model 536.772340

Paul,

I'm struggling to get my edger running smoothly again after it has sat idle for quite some time. In summary, it starts up easily (full choke, full throttle), but then I am never able to fully back off the choke without the engine oscillating and then dying. The same goes for the throttle- if I am able to find a “sweet spot” for the choke with the throttle on full (usually somewhere between ½ and ¾ choke), the engine will run relatively ok until I try to reduce the throttle, at which point it dies. It also runs better under load (blade engaged), but still not the way it should.

As you can see from this video (uploaded here; has sound: http://youtu.be/iRAILKpmA-Q ) it idles rough regardless of whether the choke is on full or off. I realize the engine is also running more lean with the air filter removed, but this was the only way I can get a good picture of the oscillation and I am not convinced that the air filter is the issue. Below is the list of what I've tried so far, based on the advice from web forums and my experience with small engine tinkering (note that I took the video after already completing all these steps, and the engine performs almost the same).

- Tore down the carburetor, cleaned it thoroughly with carb cleaner, and rebuilt it

o I cleaned the fuel line going into the carb as best I could (there's just a thin pick-up tube that draws the gas up)

o I looked at the diaphragm and it looked fine, so I did not replace it.

o I did not replace all the associated seals because they looked ok, but can certainly do so if you think that might be the issue

- Cleaned out the fuel tank and put in fresh fuel

- Cleaned the spark plug (I have not replaced the plug yet)

- Opened up the engine block and cleaned out all the carbon buildup on the piston heads and in the combustion chamber

- Removed and cleaned rust from the magneto, also cleaned the flywheel.

- Ran the engine and sprayed carb cleaner into the carb while running

My next thought was to try replacing the two springs (governor and governor idle). You can see from the video that as you move the throttle through it's stroke there's not much difference in performance- which leads me to believe the springs may not be strong enough to counter the oscillation and the bottom one may be stretched out, but I’m really not sure if that’ll help so I’m interested in your thoughts.

I only paid $150 for the edger (used, a few years old) so I don’t want to put a lot of money into it if I don’t need to.

Here's a link to the manual if it helps:

http://www.searspartsdirect.com/partsdirect/part-model/Craftsman-Parts/Edger-Par

Pages 34, 36, and 38 have the primary engine diagrams.

Thanks in advance for any help you can provide.

-Mike

AnswerHi Mike just watched the u tube video - looks like what you have described is the unit hunting and surging without any load on it it looks like it is doing at top speed no load and governed idle speeds and if try to get to idle -it stalls

1 try replacing the fuel pumping /lift diaphram on the side of carb part 272538 they are cheap , usually hunt and surge is caused by erattic fuel flow through carb or governor problem - spring part numbers are main gov 690563 and gov idle spring 691289

make sure that the throttle plate in the carb bore is not loose or binding as is the link from air vane inside flywheel cover , be absolutly sure that that the mixing chamber holes are clear - verify by blowing crc through them with compressed and watch it come out the holes

be sure the pumping section is assmebled correctly - compression spring in hole , spring cap , diaphram and cover , be sure breather vent in tank cap is clear

verify fuel can be drawn up through fuel pick up tubes>

might pay to check valve clearance ( these are under engine breather assy )

from memory 0.005 thou inlet and 0.007" thou exhaust

after going through fuel / gov systems and provided spark and compression are good engine should run

remember F A C T S Fuel , Air, Compression Timming , Spark if all are in good working order engine will run

cheers let me know what you find

hope it helps