Questionthanks for your service. engine is 404437-011401 ran fine when i bought it but connected two powerful head lights that were on it fuse blew now no spark mag looked bad the coil shorting wire was loose and frayed installed new mag air gap at .11 still no spark using a spark plug tester. starter spins the engine fairly fast thanks

Answer

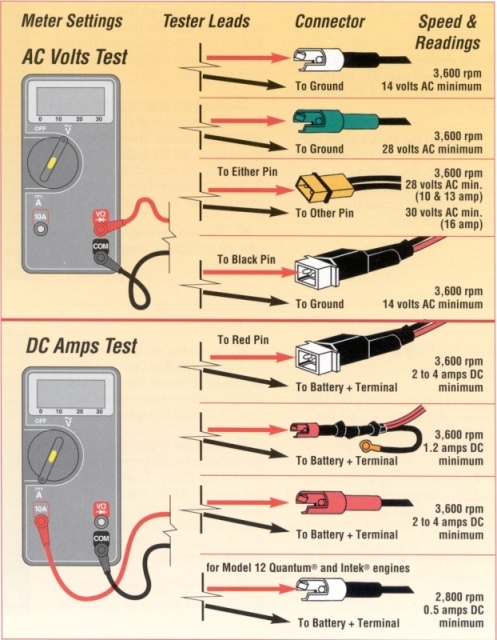

alt

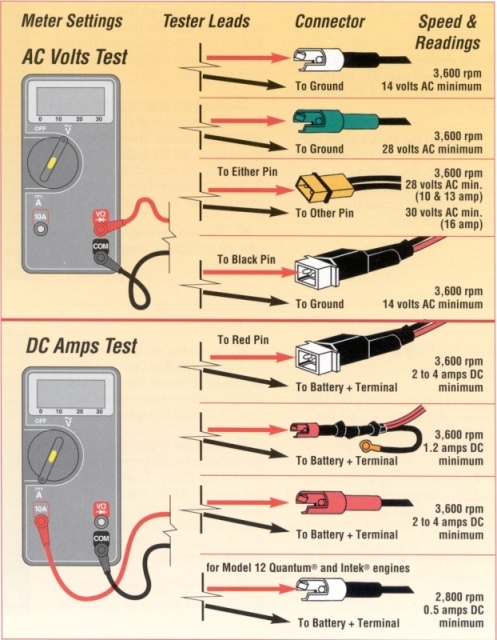

alt

David

sounds like you may have damaged the voltage regulator this part is either(10, 13, or 16 Amp, Depending on Size of Flywheel Magnets) This part may have went bad due to the excessive amount of wattage the bulbs used.The problem is knowing what alternator you have to increase it so you can use the larger bulbs,is this worth it probably not. They have 3 different type of alternators

1) is a dual circuit then there is a (Tri Circuit, 9 Amp Regulated)& a (Regulated)You need to check to see if the voltage regulator went bad. Here is how to do this.

The gap between the stator and the flywheel must be set precisely for the stator to function properly. Many stators require a .010" stator air gap.

With the engine off, locate the thin wire(s) extending from beneath the blower housing. These wires attach to the stator under the flywheel and deliver the electrical current from the stator to the battery and other electrical devices.

Note the color of the wires (scrape away any engine paint to identify the true wire color), as well as the color of the wire connector, typically an inch or two from the blower housing. For a Briggs & Stratton engine, find the same wire/connector combination on the AC Volts/DC Amps Meter Settings Chart. The chart tells you the type of test to perform (AC Volts or DC Amps), how to set your multitester leads and the correct engine test speed and multitester readings.

Use the appropriate test procedure for your engine listed below. If the wiring on your engine is not on the chart, ask your Authorized Dealer how to test your equipment.

If your engine requires an AC VOLTS test (see the AC Volts/DC Amps Meter Settings Chart), set the tester's dial to AC VOLTS and follow these steps:

Insert the black multitester lead into the tester's COM receptacle. Connect the other end to ground, such as an engine bolt or cylinder fin, or to the double connector on the stator output wires.

Insert the red lead on the multitester into the tester's AC VOLTS receptacle. Connect the red lead to the appropriate stator output wire (image A)

.

Start the engine and let it run for several minutes to read its operating temperature. Then, using a tachometer

(service part number 19598), set the engine test speed and check the reading on the tester. Replace the stator if the reading is incorrect (see the AC Volts/DC Amps Meter Settings Chart).

Turn off the engine and disconnect the multitester from your equipment.

If your engine requires a DC AMPS test (see the AC Volts/DC Amps Meter Settings Chart), set the tester's dial to DC AMPS and follow these steps:

Insert the black multitester lead into the tester's COM receptacle. Connect the other end to the battery's positive terminal. (NOTE: The battery must be grounded to the equipment frame of the engine block to create a complete circuit.)

Insert the red lead on the multitester into the tester's AMPS receptacle. Connect the red lead to the appropriate stator output wire (see the AC Volts/DC Amps Meter Settings Chart) (image B)

.

Start the engine and let it run for several minutes to reach its operating temperature. Then, using a tachometer, set the engine test speed and check the reading on the multitester. An incorrect eading indicates that the stator, diode or regulator should be replaced.

Turn off the engine and disconnect the tester from your equipment.