QuestionQUESTION: i am working on a 75 midget. had head and valves redone,great compression all cyls between 165-180. i was getting no oil pressure on a remote op gauge. removed the pan and oil pump,cleaned and checked ok. packed the pump with vasoline as a prime and it worked (tested in a coffee can filled with parts cleaner) cleaned and re packed the pump. reinstalled the pump,closed up the bottom end, new oil,cranked the engine, no pressure on the guage, but oil came out under the distributor. question after all that, is it possible to install the pump incorrectly ? thanks in advance. happy labor day jim kent, ohio

ANSWER: The only way to mis-install an oil pump is to not have the mating surfaces flush/flat when torquing down the pump. Your procedure for priming the pump is correct. You can use assembly lube instead of vaseline, too.

Your greater concern may be the clearances on the pump and associated hardware. There are clearance minimums on the pump end float, and the rotor/vanes on the oil pump. The greater the clearances, the less the pump can build pressure. These pumps are considered constant volume pump, that they pump a fixed volume with each rotation. Pressure is dependant on the pump's ability to prevent backflow, as well as the engine bearings in restricting the size of the "leaks" in the bearing clearances.

Here are some thing to check beyond the pump end float:

1) oil pressure relief valve; unscrew, clean, and make sure the mating surface isn't marred; if its stuck open, or not enough seat pressure, that can cause a pressure loss.

2) pull off the oil filter, or the port for your pressure gauge. Crank the engine, and see how much, if any, oil flows out the port. If you aren't getting any oil, go back to #1 or check the pump, or replace the pump.

3) try a different pressure gauge that is known to work; (a sanity check). THe oil pressure switch idiot light is typically triggered at 7lbs; if your oil pressure light goes out, but no pressure on your remote gauge, then the issue is more likely your gauge.

If you have flow, but not pressure, then somewhere in the circuit is a massive pressure leak, which could be any of the bearing surfaces. Bad bearing, however, usually result in a lower pressure, not no pressure. With new bearings and reground journals/kingpins, you should see pressures upwards of 90lbs cold cranking on the starter alone, 60-70 min. If you have less than that, somewhere a clearance is larger than desired, and you have more oil "leaking" at those points.

---------- FOLLOW-UP ----------

QUESTION: all signs point to the oil pump as the problem, i have had it checked by our local Porsche guy, who says it's ok. a couple of comments, op gauge was new sw right from the box,no real way to check it with the equipment i have. oil pressure relief valve, should i re place on general principals it, it is under $12. low pressure light not in operation at this time. absolutely no flow from the oil pressure port. only A-OK on the odometer and inside,oil pan and rocker arms etc. no sludge. car has sat for a very long time, approve. 6 yr. any further suggestions that you have would greatly appreciated. project on hold till we see op.

thanks again

Jim Kent Ohio

Answer

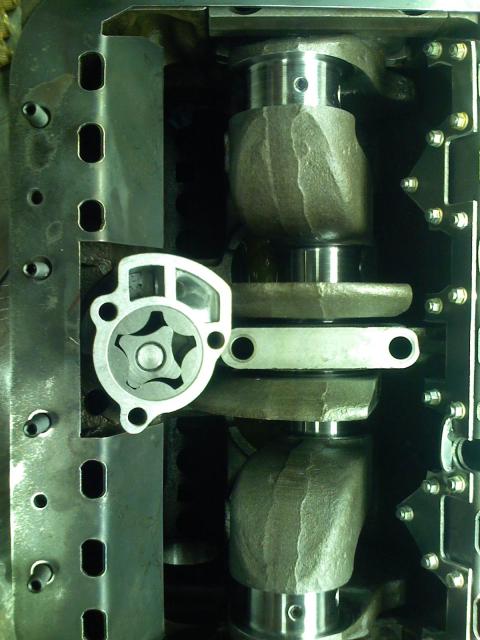

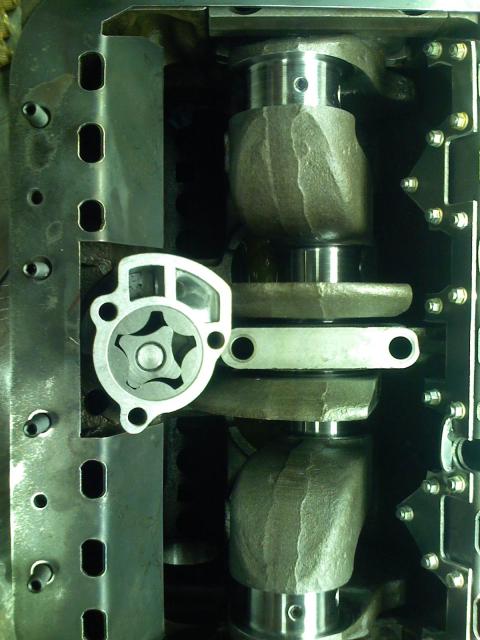

OIl pump orientation (

OIl pump orientation (

You shouldn't have to replace the oil pressure relief valve; just pull apart and clean and make sure it isn't stuck open from an obstruction or gummed up part.

Take off the oil filter.

Pull the distributor and the cam dog gear.

You will see the slotted end of the oil pump.

find or make a shaft you can mate into that slot, and can also clamp in the end of a portable drill.

Spin the drill to spin the oil pump. Once the pump primes, some oil will come up the shaft.

You will hear a change in the pitch of the drill once the oil pump suction kicks in.

Oil should then flow out of the lower port that the oil filter covered.

If that occurs, the pump and basic suction works.

If all you ever hear is the high speed pitch, the oil pump isn't able to gain suction and prime itself. I've included some pictures of the pump orientation on the 1500, which what I assume you have in your car. Make sure the exit hole on the top of the pump lines up with the corresponding hole on the block. Make sure that the connector from the pickup screen into the pump doesn't have a break or hole.

If it comes up the shaft where you have the drill, but never comes out where the oil filter connects, then there is a blockage somewhere in that passage between the pump, oil pressure relief, and the oil filter connection.