Fuel hoses come in a variety of shapes and sizes for all engine applications where fuel must be delivered to the intake system for combustion. Certain standards must be met, since choosing the wrong hose can have adverse effects upon fuel delivery and be potentially dangerous. Hoses are rated for different applications, including automotive (gas and diesel), marine, aircraft and high-end industrial systems. They can be braided steet, solid metal, rubber or even plastic. They all have a specific job to perform, whatever their type. The most common types are found on passenger vehicles and trucks. One you know the correct size and type, you can replace fuel system lines with ease and confidence.

Car and small truck automotive engines typically require high-strength composite hoses made of rubber and plastic. These hoses have thick rubber lining designed to stave off static electricity. Pliable and resistant to shock, age, and pressure, they will often last for the lifetime of the vehicle if cared for properly. They come equipped with ratings, with most sizes ranging from 3/8 inch to 1/2 inch in diameter. Lengths of automotive hose can be bought and cut directly off spools to desired lengths. Fuel hose specifications can vary with import cars and trucks, since different fuels and octane ratings apply, mandated by the manufacturer.

Diesel hoses have a bit more work to do, particularly on diesel injected systems. Many have temperature ratings and have sturdier construction. They range is size from 1/4 inch up to 4 inches in diameter. Diesel hoses commonly have a discharge and suction side, equipped with special leak-proof fittings. Although they are used in big rig transport trucks, they also serve in marine applications, able to withstand the extra pressures required from larger fuel-injected diesel engines.

The U,S. Coast Guard recognizes four types of diesel hose for marine applications, A1, A2, B1, and B2. All these hoses have special treatments in their construction to ward off salt, oil and water contamination. The Coast Guard recommends the Type B for hoses affixed to the carburetor and fuel pump for all marine uses and as the best option for gasoline use. The Type B hose is also resistant to fire. The Type B1 serves the best application for all diesel engines.

The Type A1 gasoline hoses have a higher rating and are used in the most critically demanding situations. Their construction makes them less permeable, with extreme durability and heat resistance. The Type A1 hose is made to hold its form and not collapse under extreme pressure. The Type A1 serves best in gasoline applications.

The mark "USCG" can be seen stamped on the hose every 12 inches, including the manufacturing date.

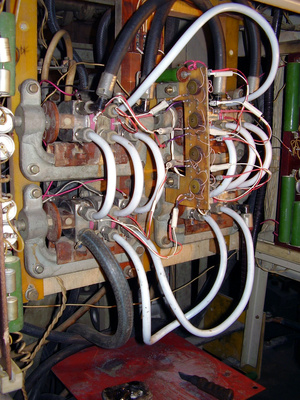

Fuel lines and hoses for aircraft incorporate the best of both worlds. They use high composite inner rubber construction, with the addition of heat shields, in the form of sleeves or steel braided design. They are rated by federal aircraft agencies for the highest quality. They also possess the highest rating and quality for fire resistance.

Note: Hot rod dragsters typically use steel-braided aircraft fuel lines, due to the tremendous pressures and heat-retardant qualities.