GM installs Dana-built differentials on its cars and trucks. The differential is the big box in the middle of the drive axle on both front and rear-wheel drive vehicles. The drive shaft turns and is parallel to the vehicle's frame. The drive shaft is connected to the differential gear and turns the axles placed perpendicular to the frame (the power is turned a different direction, thus a differential.) Different GM products have different size differentials, depending on the engine horsepower, the amount of torque (or twisting energy) and wheel size connected to the differential through the axles.

You do not have to remove the axle to repair the differential unless the differential case is damaged. Any repair on the differential gear on a GM product begins by disconnecting the drive shaft. The differential gear case contains fluid that is used to both lubricate and cool the gears. Remove the fluid using the drain plug. You will use new fresh fluid after completing the repairs so do not worry about saving the old material.

The differential case is sealed on one side by a plate held on with four, six or eight bolts, depending on your model GM vehicle. Remove the bolts and remove the plate. Be careful because some residual slippery fluid will leak out.

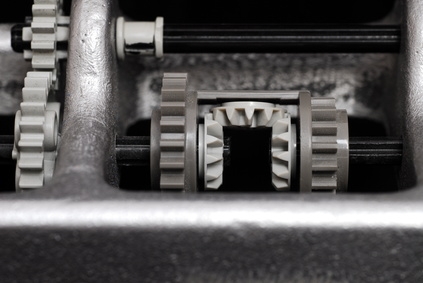

Once the plate is open you will see two helical gears held by C-clips and cross pins to the axle shaft. Remove these clips and pins. Then pry the gears off and remove them.

Replace all bearings. You will need a bearing puller and press to remove and replace the bearings. Bearings showing any wear in the bearing races (the track where they spin) or uneven ball bearings need replacement. Inspect the gears for any wear or unevenness. Make sure the gear teeth mesh completely to the bottom. Low gear teeth and improper mesh can lead to gear slip. Clean all the parts thoroughly. Replace any parts showing extreme wear.

Once all parts are inspected and necessary replacements made, reinstall the gears using shims to get the correct gear mesh. Do not push the gears too close or set them too far apart as they can bind. Again, shallow gear depth can cause gear slip. Once shimmed to the proper depth, use new pins and C-clips to secure the gears. Also, replace the gasket seal on the differential plate cover. Reinstall the cover and add fresh gear oil to the differential case.