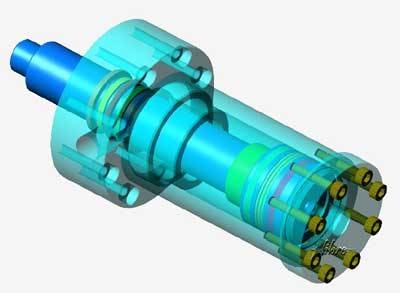

An hydraulic cylinder operates through pressurized fluid (usually oil), which gives the hydraulic cylinder force. The cylinder's driving force is the piston, which is attached to a piston rod that is enclosed in the cylinder's barrel. The bottom of the barrel is closed off by the cylinder cap and the top is closed off by the head. The head contains a round hole, which allows the piston rod to come out of the barrel. The inside of the barrel contains the oil, and the hydraulic pressure that the oil creates acts on the piston rod, causing it to move back and forth in a linear fashion. One end of the piston is attached to the object or machine it is responsible for moving. As the hydraulic pressure of the oil moves the piston rod, the piston rod moves the piston, which in turn moves the attached object.

There are two main types of hydraulic cylinders: the tie rod cylinder and the welded body cylinder. The tie rod hydraulic cylinder contains threaded steel rods attached to either end of the cylinder barrel. These threaded steel rods are extremely strong and make the tie rod cylinder useful in heavy-duty industrial applications. A welded body cylinder has no steel rods. Instead, the top end of the barrel is welded directly to the object that it is designed to move. Because it has no steel rods, a welded body cylinder is much smaller than a tie rod cylinder and is used in smaller machinery. The welded body cylinder is the main hydraulic cylinder used in construction machinery. There are other types of specialized hydraulic cylinders, including the telescoping cylinder that allows the piston rod to retract into the barrel. Specialized hydraulic cylinders are primarily used in custom machinery and specialized industrial equipment.