Harry Wagner

Contributor

Harry Wagner

Contributor

People love the old faded paint and ranch look of our ’77 F-150, Raymond, and we do too. We were not as in love with the interior though, which was smelly, noisy, and not particularly comfortable. For a few days of goofing off with friends at Cheap Truck Challenge it is no big deal having to reach inside the truck to open the door because the handle is broken, or having 2-inch sheetmetal screws above your head holding the wrong cab lights onto the roof. But after a while these things start to nag and you find that you aren’t driving your truck as much as you might be if it were more comfortable. Enter LMC Truck.

Call us soft, but we believe that a nice interior makes your truck more enjoyable on-road and off, particularly on trips like the Ultimate Adventure, where we are literally living out of our truck for a week or more. Speaking of the UA, another requirement of the trip is a rollcage. Even if you never go on the UA, a rollcage is a good idea, and we mentioned back in the Aug. ’14 issue that a cage was the last major upgrade for our Ford (“Everybody Loves Raymond”). The tricky part is adding the security of a properly designed and built rollcage without actually making the interior less comfortable through errors like having bars that hit your head or knees or that don’t allow you access to the emergency brake pedal or window rollers.

We headed to Nate’s Precision, Raymond’s official build shop, to have the crew build us a custom rollcage and fill our Ford with new door seals, flooring, and dash components from LMC. The result is not only safer but also more comfortable and quieter. As a result we drive the truck more often, and isn’t that the point?

The interior of our truck was pretty roached when we bought it for Cheap Truck Challenge, but the condition was reflected in the price. The body was straight and relatively rust-free, and we figured the interior would be easier to upgrade with parts from LMC than the body or the frame.

The first thing Nate Jensen and Bernie Dittrich do before bending a single tube is ask questions about the intended use of a vehicle and budget for the project, then suggest options. We wanted something simple and basic for this truck.

Nate’s Precision pulled the doors and the windshield off the truck and took measurements. Our cage went through the dash and tied into the frame. Other options include details such as dash bars, tying seats and harnesses into the cage, and tying the cage into the frame.

After taking all the measurements, Dittrich transferred his measurements to the concrete floor. This way he could quickly and easily lay the bars out and ensure that they were the proper fit. If you are new to fabrication, stick to items like bumpers and rock sliders for your first projects with tube bending and welding. Make certain that you are comfortable with the tools before you tackle a safety item like a rollcage.

A quality tube notcher is critical for creating tubes that fit together tightly. The better the fitment of the tubes is, the stronger the cage will be and the less gap the welder will have to fill.

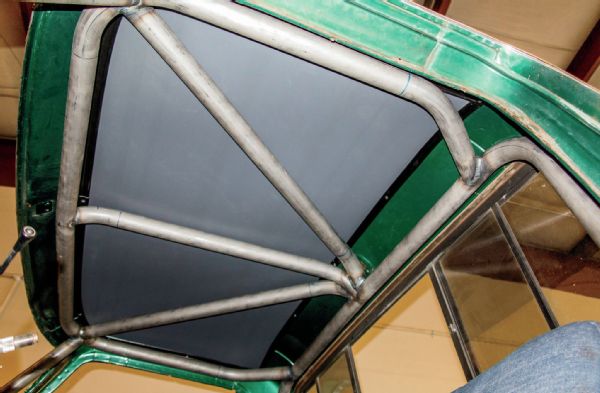

Dittrich taught us a trick about how to weld 360 degrees around the tubes with the cage in the truck. After removing the windshield he was able to tilt the entire cage forward to access the bars. Then the cage was positioned upright and the A-pillar bars were fully welded before the windshield was reinstalled.

The cage fit so tightly that we had to install the new LMC headliner prior to final-welding the rollcage. The center bars add strength to the cage without placing a bar directly over the driver’s or passenger’s head, adding head room.

The guys from Eric’s Mobile Glass came to us to install a new windshield in our F-150. The old glass broke while we were removing it, but it wasn’t until we got the new windshield in that we realized how pitted the original windshield was.

Our Ford came to us with no door panels, a vise grip to roll down the driver-side window, and a door that would only open from the inside. LMC had all the parts in stock to fix these problems and more.

The new door panels from LMC were a perfect fit and really cleaned up the interior of our truck. The only issue we had was that we installed the door panels prior to replacing the window seals and when removing the door panels we broke the “Christmas tree” fasteners for the panels. They are cheap, so we recommend ordering extras so you have them on hand.

New weatherstripping from LMC sealed our windows and doors and made the truck much quieter at highway speeds. Now instead of the wind we just hear the sweet sound of the LA Speed–built 460 engine.

LMC also carries replacement HVAC parts. We replaced the leaking heater core, blower fan, and blower resistor while we had the interior apart. Bring on the snow wheeling!

The new dash pad from LMC bolted right in place of the stock parts. LMC carries a huge selection of replacement interior and exterior parts for various generations of Chevy, GMC, Dodge, and Ford trucks. No need to scour the wrecking yards only to find a dash that is in worse shape than the one you are trying to replace.

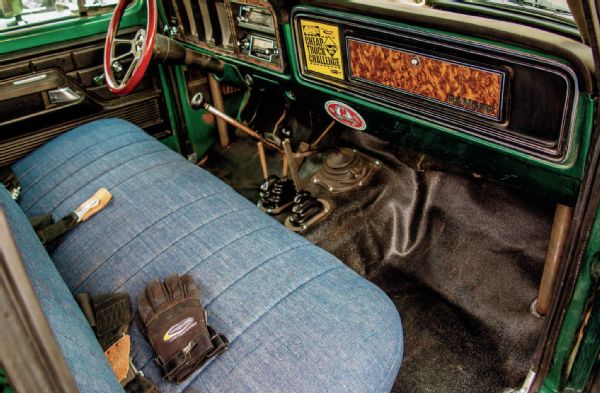

We used a rubber floor mat instead of carpeting to ease cleanup after a day on the trail. The flooring was molded for our cab, but we had to cut out holes for the cage and shift levers for our NP435 transmission and Offroad Design doubler.

Summit Racing Equipment had this Longacre Products mirror in stock, and it came with the clamps to bolt it directly to our 13⁄4-inch rollcage tubing. These parabolic mirrors give a wide view, making them a great choice for a vehicle used on the street and the trail.

We had our factory bench seat recovered in denim locally. Behind the seat we mounted Trail-Gear fluid carriers, a set of jumper cables, and an H3R fire extinguisher from Summit. These items are all safely secured and out of the way, yet easy to access.

Trail-Gear makes race car quality fluid carriers to fit 2 quarts, 4 quarts, 6 quarts, or 2 gallons. All are CNC laser-cut and formed out of 16-gauge steel. The spring draw latch has a 200-pound breaking force and features a safety catch to prevent accidental openings.

The LMC components made the truck dramatically quieter inside. We had not considered how much noise would affect driver fatigue. Now the Ford is much more enjoyable to drive.

This was the last major upgrade our reformed Cheap Truck needed, and it should have happened a long time ago. Now we can wheel more difficult trails without having to worry about our safety in the event of a rollover.

MIG or TIG?

Our cage was entirely TIG-welded from 13⁄4x0.120-wall DOM tubing. TIG welding is a more time consuming process than MIG welding, both in the welding itself and because TIG welding requires precise tube fitment with no allowance for gaps. So what are the advantages of TIG-welding a rollcage? “Well, it doesn’t leave any burn holes in your new seat,” Bernie Dittrich quipped. You have heard of Top Gear’s Stig? Well, Dittrich is like the Stig’s fabricator brother, the Tig. Dittrich prefers the control he has over filler material and heat with TIG welding compared to MIG welding. That being said, he feels that the design of the cage and material chosen have a bigger effect on strength than the welding method does, assuming that it is properly performed.