Christian Hazel

Brand Manager, Four Wheeler

Christian Hazel

Brand Manager, Four Wheeler

If you own a ’03-’07 Ram 2500/3500 4x4 or 1500 Mega Cab 4x4, you’ve probably spent a fair amount of time pulling a trailer or hauling heavy stuff in the bed. And even if you don’t, you do occasionally drive it, don’t you? And during any of these outings, you’ve probably noticed something while trying to keep your 3-ton behemoth between the reflectors on the highway: They steer like a lazy pig on a greased roller rink. It’s a gradual progression that you don’t really notice overnight. They handle pretty well straight off the dealer lot, but after a few months, the frontend starts going wherever it wants to and after a couple years your hands look like a WWII aircraft carrier landing signal officer as you frenetically saw the wheel back and forth to keep it in the lanes. And that’s not even talking about death wobble, prematurely worn tires, or any of the other bad traits that manifest in these trucks.

The reasons for this are tri-fold. First, the ball joints in the AAM front axle have horrible durability. After only about 35,000 miles, our ’07 Cummins-powered Ram 2500 had worn out its ball joints so badly the knuckles moved if you jacked the front end off the ground and wiggled the tires. We replaced the ball joints with Dynatrac ball joints and the problem improved. The second is the factory unitbearing hubs, which were goners after roughly 45,000 miles. The same test that highlighted the worn ball joints told us our driver-side unitbearing hub was toast, so on went a Dynatrac Free Spin hub conversion kit. Steering improved even more and with the hubs unlocked, steering felt lighter and more precise. The third is the factory steering gear and linkage that’s too mealy and overworked for the heavy Ram chassis. The Y-shaped drag link and tie rod allow the toe setting to change as the suspension compresses and droops, which contributed to wander and increased tire wear. And the steering box sector shaft bushing in our truck had developed enough slop that we could grab the pitman arm and wiggle it around by hand. The final penny had dropped.

Our order from PSC included a completely reworked ’09-up Ram steering gear with fittings for a hydraulic ram, the ram-assist cylinder and hardware, fitting and lines, ram mounting hardware, a Borgeson steering shaft, and an ’09-up pitman arm. Also not seen is the new high-pressure line since the ’09 box has a different fitting than the factory ’07 box on our truck.

Our order from PSC included a completely reworked ’09-up Ram steering gear with fittings for a hydraulic ram, the ram-assist cylinder and hardware, fitting and lines, ram mounting hardware, a Borgeson steering shaft, and an ’09-up pitman arm. Also not seen is the new high-pressure line since the ’09 box has a different fitting than the factory ’07 box on our truck.

Ram apparently realized the problem as well because the ’09 trucks came with a much-improved T-shaped linkage with a one-piece tie rod and dedicated drag link as well as a much beefier steering gear. We put in a call to Dynatrac, an authorized Mopar dealer, and purchased a new Mopar T-linkage setup for an ’09 Ram pickup (PN 52122362AE). We then called up PSC Motorsports for the rest of the parts we’d need to convert our ’07 steering gear over to the improved ’09 setup, including an ’09-style pitman arm, high-pressure line, and Borgeson steering shaft (PN 000951). For the steering gear, we chose to go with PSC’s reworked unit rather than regular off-the-shelf Mopar ’09 gear. PSC cracks open the new box and adds fittings for a ram-assist cylinder and alters the torsion spring so the steering feel isn’t absurdly light once the ram is added.

We did the box swap in our driveway and tested it for a while without the ram and with the factory Y-shaped steering linkage. The steering feel was much improved. The PSC box felt incredibly tight, and we noticed much, if not all, of the vagueness and wander was gone. The truck just felt tight and went down the middle of the freeway lane like a slot car. After a couple weeks to get used to the new box, we visited a buddy’s shop to have the T-linkage installed, during which time we hooked up the hydraulic-assist ram. Oddly enough, the ram didn’t do much, if anything, to the steering effort. However, what the ram did do is act like a steering stabilizer on steroids by isolating any jolts or bump impacts from the steering wheel. It also takes all of the strain off the steering gear’s sector shaft and frame mount. The T-linkage really helped any remaining wander issues the truck had been hanging on to. After our upgrades, the ’07 Ram we purchased new off the dealer lot was more controllable and handled better than it ever had.

PhotosView SlideshowCheck out the beefy ’09 box in comparison to our factory ’07 box. The difference in piston size between the ’09 box and the earlier box is obvious, as is the increased size of the sector shaft and bushing.

The pitman arm for the late-model T-linkage is angled down further than that of the earlier Y-linkage. You can use the late-model pitman arm with the earlier Y-linkage. Although it may work, it’s best to use the late-model pitman arm with the later T-linkage since the T-linkage drag link has a straighter angle and the tie-rod end could bind.

More differences: The new box’s input shaft is a smooth 3⁄4-inch DD, while the older box is splined. As such, you need a new steering shaft.

You can reuse the older low-pressure return line on the newer box, but the high-pressure line fitting is different. Thankfully, the factory ’09-present high-pressure hose connects right to the hydroboost line in the earlier truck.

We used high-quality Royal Purple full-synthetic Max EZ power steering fluid in our new, expensive upgrade. We lubed the O-rings and fittings so they wouldn’t get nicked or damaged while replacing and transferring the pressure and return lines. The new steering gear bolts right to the frame mount in place of the original box.

We gave the new Borgeson steering shaft a coat of paint and then prepped it for install. The column isn’t collapsible, but install is easy if you slide the column end of the shaft up on the steering column side, and then you can pull the U-joint forward onto the box.

Make sure to use red thread locker on the steering shaft set screws or it will loosen and fall off, especially with the vibrations from a Cummins turbodiesel.

Make sure the steering wheel and box are centered before you attach the steering shaft. You don’t want to have your steering wheel upside-down when the wheels are pointed forward. Tighten all the hardware to spec. It’s always a good idea to use a paint pen and mark the set screw nuts so you can see at a glance if they’ve loosened.

With the box, lines, and shaft attached and tightened, we installed the new pitman arm, cinching down the nut with a humongous 113⁄16-inch socket. We used a Snap-On torque wrench to get to the required 225 ft-lb on the pitman arm nut. We then hooked up the factory ’07 Y-linkage to the new pitman arm for our first wave of testing.

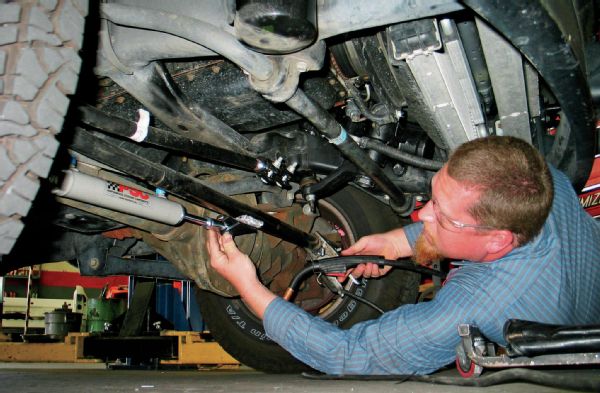

With several thousand miles of testing on just the steering box upgrade, we brought the ’07 Ram to our buddy’s shop to install the T-linkage and PSC ram-assist cylinder. Notice the factory steering stabilizer. We surmised we could use the factory axle mount for the PSC ram.

The ’09-present T-linkage (top) features a true one-piece tie rod versus the ’03-’08 Y-linkage, which uses the same arrangement as a Jeep TJ and allows the toe setting to change as the front suspension cycles. We removed the bolt-on steering stabilizer mount from the T-linkage and installed it on the vehicle.

PhotosView SlideshowPSC includes high-quality rod ends with high-misalignment spacers. It just so happened they were a perfect fit for the factory steering stabilizer mount on the axle. If we were building a rock crawler with 54-inch tires, we’d probably use a heavier mount, but for a street-driven tow rig with 35s, it’s more than adequate.

We centered the ram in its stroke and made sure the front tires were pointed straight forward before determining our tie-rod mount location. We removed the paint and tacked the PSC tabs in place.

We removed the ram to prevent weld spatter from harming it and fully burned in the tabs to the drag link. When it cooled, we hit it with some black chassis spray paint and reinstalled the ram.

With the ram mounted, it was time to build the lines. PSC uses very high-quality fittings and hose that are much easier to assemble than braided line. We lubed the fitting ends with the same Royal Purple Max EZ fluid we filled the reservoir with.

Make sure when you’re assembling your lines you orient the fittings, as they’ll lie in the chassis. If you wind up needing to twist the lines, they’ll try to straighten out under pressure and may loosen up and leak over time.

We routed the lines up along the track bar, ensuring they were secured and wouldn’t get hit by the steering linkage and wouldn’t get abraded as the suspension cycled.

The final step is to top off the steering fluid and bleed the air out of the system. PSC has an excellent procedure for this on its website, but the trick is to take your time and make sure you’re giving the bubbles time to work their way out of the system.