Sean P. Holman

Contributor

Photographers:

Ken BrubakerChrysler, LLC

Sean P. Holman

Contributor

Photographers:

Ken BrubakerChrysler, LLC

One of the primary topics of conversation within the pages of Four Wheeler, as well out on the Internet and amongst wheeling enthusiasts, is suspension. Suspension is one of the most important aspects of any four-wheel-drive vehicle, but can be an intimidating topic for anyone new to the sport.

To gather up all of the facts, we headed over to see our good friends and suspension experts at Deaver Spring in Santa Ana, California. Deaver has been around since 1982, manufacturing quality OE-replacement and custom suspension springs for virtually any application imaginable and has been an important resource on many of our project vehicles.

We'll walk you through what makes torsion bars, coils, and leaf springs different, and the pros and cons of each. Of course, you'll want to keep in mind that what we'll cover is in general terms, and there are exceptions out there.

Spring Time

A spring is any type of material that, when distorted, returns to its original shape. The job of the spring is to support the weight of a vehicle, maintain ride height, and keep the tires in contact with the road surface. Springs are used in conjunction with shocks, or dampers, which actually control the suspension movement. Three of the most common types of springs in use today are the torsion bar, coil spring, and leaf spring.

These two coils are different. The one on the left is a linear-rate unit, while the one on the right is a variable rate. Note the difference in spacing between the winding on the variable-rate coil.

These two coils are different. The one on the left is a linear-rate unit, while the one on the right is a variable rate. Note the difference in spacing between the winding on the variable-rate coil.

A good spring maximizes wheel travel, ride comfort and load-carrying ability. Springs are built with spring rate in mind. Spring rate is the amount of force that is required to move a spring and is measured in pound-force per inch (lb-in). Load rate is also a consideration, which is the amount of weight the spring is designed to carry at ride height.

Leaf Springs

The leaf spring dates back to medieval times and is one of the simplest and oldest forms of spring technology. Early leaf springs used leather instead of the metal we are familiar with today. A standard of automotive suspension systems for decades, the role of the leaf spring is slowly being reduced-even in applications where it has been the stalwart, such as pickups. Over the last 10 years or so, we have seen the leaf spring replaced by coils in Jeeps, in the front of heavy-duty trucks, and most recently in the rear of the light-duty Ram 1500.

Like all leaf springs, this one is progressive. However, it is also a two-stage spring due to the overload spring at the bottom of the pack. This 5-inch lift pack is for the rear of a Ford Super Duty.

Like all leaf springs, this one is progressive. However, it is also a two-stage spring due to the overload spring at the bottom of the pack. This 5-inch lift pack is for the rear of a Ford Super Duty.

Modern leaf springs use a series of steel plates of varying length and thickness, known as leaves, bound together in a pack. Some suspensions use a monoleaf design, which only uses one leaf in place of a pack. The number and thickness of these leaves are what dictate spring rate and load capacity. The overall length has an effect on ride quality, while the width of the leaf and whether it is mounted inboard or outboard all have an effect on stability.

Because of their tapered shape, leaf springs-including monoleaves-are progressive-rate springs. This means they grow stiffer the more they are compressed, which makes them superior for heavy load carrying than so-called single- or linear-rate (i.e., coil) springs. Leaf springs are also modular, meaning that if you desire a change in ride height or capability, all you have to do is add or remove leaves. The higher-quality packs will use multiple, thinner leaves to reduce friction. This stacking of leaves also makes for a more durable product because one leaf isn't holding the entire load, and if one were to break, chances are that the others will hold together long enough to get you home.

This full tapered spring is on OE replacement for the front of a Super Duty. Having fewer leaves in the spring pack can mean decreased friction and noise, as well as decreased cost for the manufacturer. A multiple spring pack replacement would give a much smoother ride while giving nothing up in capability.

This full tapered spring is on OE replacement for the front of a Super Duty. Having fewer leaves in the spring pack can mean decreased friction and noise, as well as decreased cost for the manufacturer. A multiple spring pack replacement would give a much smoother ride while giving nothing up in capability.

While all leaf springs are progressive-rate, some spring packs are two-stage. Two stage spring packs keep the progressive pack, but add an overload spring underneath to gain maximum load rating while retaining good ride characteristics when unladen. These packs are typically used in the rear of pickup trucks.

Although the design of a leaf pack itself is fairly complex, overall it is the simplest form of suspension design because the leaf packs both control and locate the axle without the need for control arms. Leaf springs also have the benefit of better stability, especially when hauling or towing at or near the rated maximum, by reducing sway and spreading out the load over a greater portion of the chassis. The downside is that they take up a lot of room to mount. Other leaf spring drawbacks are heavy weight and the susceptibility to axlewrap and noise.

Pros: Locate and control the axle, superior stability when loaded, simple, easier to lift.

Cons: Harder to tune for ride, heavy weight, prone to axlewrap, take up a lot of space, susceptible to noise.

Torsion Bars

Torsion bars are perhaps the least common springs in use today, but are still used in a number of current General Motors vehicles, especially the heavy-duty line of pickup trucks. Other 4x4 vehicles to use torsion bars over the years are Toyota IFS (pre-Tacoma) trucks, '98-to-current Ford Rangers, Dodge pickups, and Hummer H3s, to name a few.

Here is a view of the torsion bars on a Chevy 2500 HD with a BDS suspension lift. One end of the torsion bar is mounted to the chassis (fixed), while the other is mounted to the control arm (movable).

Here is a view of the torsion bars on a Chevy 2500 HD with a BDS suspension lift. One end of the torsion bar is mounted to the chassis (fixed), while the other is mounted to the control arm (movable).

The torsion bar, or torsion spring, is a long metal bar that is attached to a fixed mount on the chassis on one end and attached to the suspension-typically, a lever that is mounted perpendicular to the direction the torsion bar is mounted (a control arm, for example)-on the other end. As the wheel moves up and down, the torsion bar twists on its axis, resisting the suspension movement and returning it to center. The strength, spring rate, and load-carrying capacity of torsion bars are determined by the thickness and length of the bar.

Perhaps the simplest form of all springs, torsion bars are known for their durability and ease of replacement and maintenance. Small changes in ride height are achievable through "twisting" or "cranking" of the bars, which effectively moves ride height to a different part of the suspension travel by adjusting the torsion bar preload through the adjuster nut. However, this will limit downtravel, or droop, diminishing ride quality. Additionally, it can contribute to other negative effects if it goes beyond the generally accepted "safe" range of 11/2 to two inches (depending on the vehicle, of course).

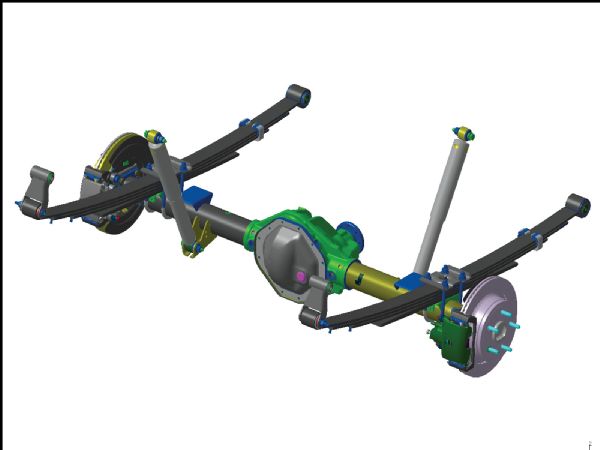

This is a CAD drawing of a Chrysler axle on the rear of a Ram 1500. This is the older leaf-sprung suspension.

This is a CAD drawing of a Chrysler axle on the rear of a Ram 1500. This is the older leaf-sprung suspension.

Other drawbacks to torsion bars are a lack of a progressive- or variable-rate option, giving a torsion bar less flexibility when loaded or going over harsh terrain, along with limited wheel travel.

Pros: Durable, simple, easy to make minor adjustments in ride height.

Cons: Spring rate not progressive, limited wheel travel, few aftermarket options.

Coil Spring

Because of the excellent ride characteristics, low noise, and ease of manufacturing, compression coil springs are the most common type of automotive spring in use today. A compression coil spring is a metal wire that has been wound into the shape of a helix to resist compression. A coil spring's rate is determined by the thickness of the wire and pitch of the winding.

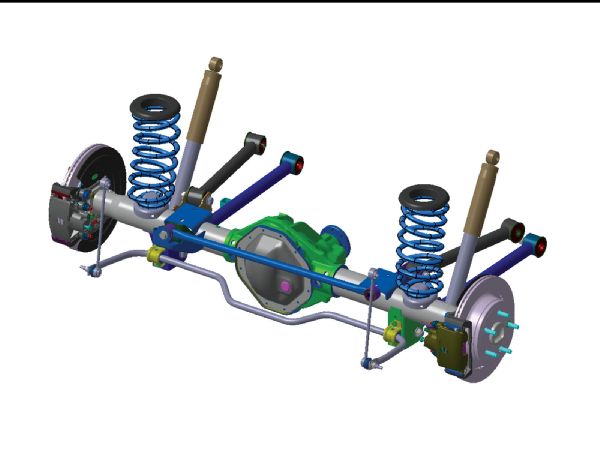

This is a CAD drawing of the same Chrysler axle with the new coil-sprung suspension. Despite being more complex, the coil-sprung suspension saves Chrysler 40 pounds of weight and provides vastly improved ride and handling, while losing very little in capability on the '09-and-later Ram 1500.

This is a CAD drawing of the same Chrysler axle with the new coil-sprung suspension. Despite being more complex, the coil-sprung suspension saves Chrysler 40 pounds of weight and provides vastly improved ride and handling, while losing very little in capability on the '09-and-later Ram 1500.

Coil springs can either be linear- or variable-rate, and you can easily spot the difference between them. A variable-rate coil spring is wound with varying pitch and spacing, and is designed to be softer first and firmer later. Variable-rate coil springs are used when a firmer spring rate is desired to handle more weight, decrease sway, and improve handling without sacrificing ride quality. A linear-rate coil has equally-spaced windings and will maintain the same rate throughout its compression travel.

Additional benefits of the coil spring include compact size, ability to precisely tune the suspension, as well as excellent articulation and wheel travel. Coils also have no internal friction and weigh much less than leaf springs.

While the benefits are many, these benefits do come at a cost. Because coils don't locate the axle, they require links to work. Those links, while adding expense and complexity to a suspension's design, are what makes a coil-sprung suspension so good at resisting axlewrap. Coil springs are also limited to how tall they can get. The taller the coil, the more they are prone to bowing or deflection, which can diminish their effectiveness over time and cause interference issues. Additionally, coil springs, when repeatedly loaded to the max, can weaken or sag prematurely and are not as durable as leaf springs in heavy-duty applications.

Pros: Quiet, better ride, easier to tune, lighter weight, eliminate axlewrap, capable of big articulation.

Cons: Need links, can sag over time or if overloaded, more susceptible to sway, expensive to retrofit, limited lift heights, not as robust as leaf springs.

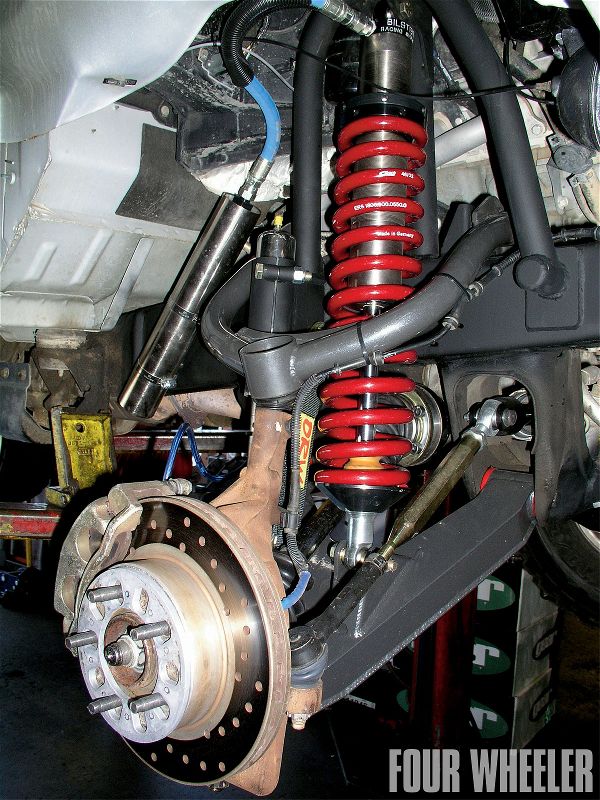

What About Coilovers?

Once thought of as purely for race applications, coilovers have gained a huge amount of popularity over the last several years. Even more compact to mount than coil springs, a coilover includes the damper (shock) and coil spring in the same unit, and because the coil spring is mounted to the shock and not the car, greater lift heights are achievable without coil deflection. Coilovers also mount with hemispherical bearings, which essentially allow the coilover to move on its mounts, preventing bind under articulation.

Coilovers further distance themselves from other spring setups by their incredible range of adjustability and their ability to run a two-stage spring setup. Changing spring rates is as easy as pulling the unit and swapping to a different coil. Threaded bodies allow preload and ride height to also be easily changed, all while the coilover is still mounted on the vehicle.

The biggest drawback to a coilover setup is the expense of the unit itself, as well as the fabrication work that may be required to fit one on a vehicle, as most coilovers are not direct replacement units.