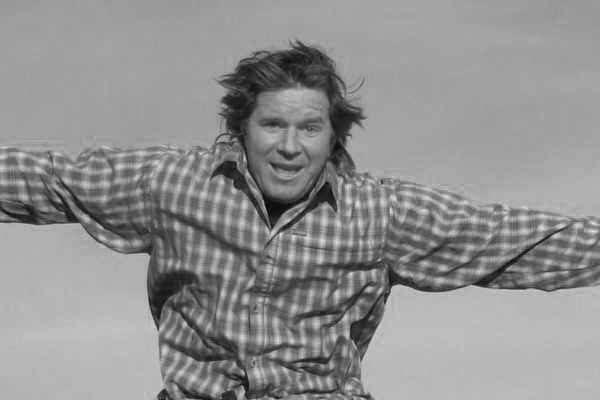

Fred Williams

Brand Manager, Petersen’s 4Wheel & Off Road

Fred Williams

Brand Manager, Petersen’s 4Wheel & Off Road

In The Past Two Decades Link-style suspensions have gone from a desert-race exclusive to something being built in garages and barns across the nation-and for good reason. Link suspensions separate the jobs so that each component of the suspension can do its part exclusively and thus better. For example, the springs on a link suspension don't locate the axle like a leaf-sprung suspension, so axlewrap is eliminated. Since the links move the axles in an arc that can follow the driveshaft, U-joint bind is often reduced. Approach and departure angles can also be increased since the links do not stick out past the axletubes.

Where do you start when it comes to building the links themselves? The market is flush with different types of rod ends, flexy joints, and bushings to go on either end of the suspension links. We've seen links made of everything from aluminum to square tube, but which is right for you? Here is the lowdown on the latest link-builder parts for your perusal.

These nonrebuildable rod ends are also referred to as Heim joints. The three major ends that show up on 4x4s are made by FK, Aurora, and QA1. They consist of a swiveling ball inside a forged outer body and come as either a three-piece (FK, Aurora), where the ball and race is swagged into the body; or as a two-piece, where the rod end is inserted in the body and rotated and then a plastic filler is injected around the spherical end (QA1). Some rod ends have a Teflon liner around the sphere for longevity and silent movement. Rod ends are described by the diameter of the shank and the diameter of the sphere bore, such that the upper joints are 1.25 by 1 inch. In order to get additional angle out of the rod end, misalignment spacers are used (arrow). These allow the rod end to twist to a greater degree than if the tabs were right against the sphere. The nuts on the shank of the joints are known as jam nuts. These are tightened against the end of the link to keep the link from unscrewing. Also note the shoulder, or step, around the sphere bore on the smaller rod ends in the lower center and right of the photo. These are for additional misalignment and are often used on steering links.