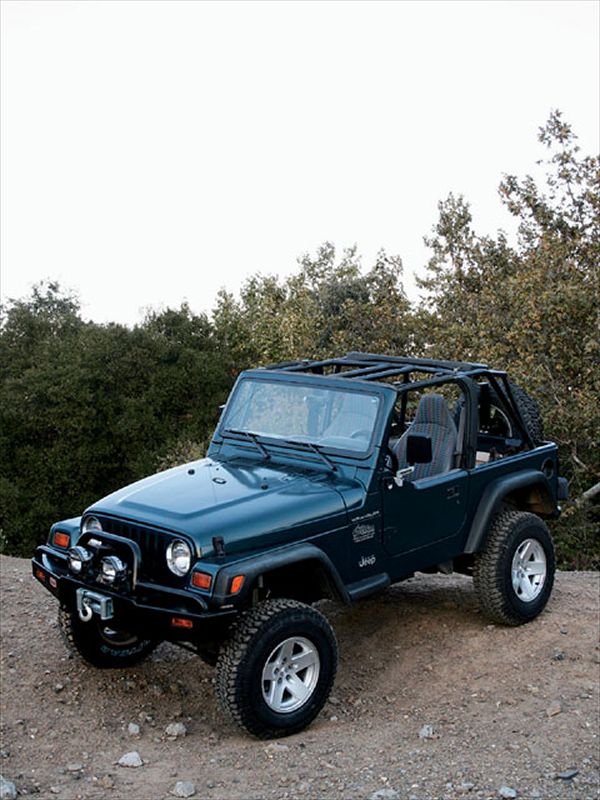

With as little as one day in the shop, our donor '97 TJ took on a whole new personality.

With as little as one day in the shop, our donor '97 TJ took on a whole new personality.

Plagued by bare-bones interiors and what many consider a bouncy ride character, Jeep Wranglers built between 1997 and 2006 often delight those of us with an eye towards the outdoors. Their nimble size, along with an arsenal of trail-proven attributes, make any TJ a trustworthy 4x4 right out of the box. And it's for this reason why so many enthusiasts begin buildups with them. Most popular amongst hard-core Jeepers are the smooth-riding long-arm suspension systems.

While long-arm conversions may seem like all the rage these days, they also have a few inherent drawbacks. For instance, installation time usually takes more than double that of a typical short-arm kit. Also, once you cut off all the unnecessary OE parts, a long-arm kit is often irreversible, or at the very least extremely difficult to return to stock. Not to mention the added expense associated with more complex kits. On the flip side, short-arm systems do not require a change in factory pivot points, and while most short-arm kits retain the factory-like ride mentioned earlier, they do offer greater simplicity while effectively achieving the end-all goal: Accommodating larger tires and improving flex.

We recently came across the new J-Spec short-arm kit from JKS Manufacturing. A closer look revealed quite a few innovations worth mentioning. So we procured a Stage 4 system and promptly secured use of a donor TJ to perform a six-month evaluation. The installation was a breeze compared to the typical long-arm kit, and our capable friends at Overkill Jeep Fabrication in Campbell, California, made quick work of it in just one short day. Now read on and see what makes the J-Spec suspension system ready to rock.

Because our donor Jeep had a slightly bent tie rod, we decided it was a good idea to upgrade the stock steering while we had it up on a lift. We chose the third-generation U-Turn kit from Off-Road Only. We like this particular kit because it was designed to correct steering geometry, thus eliminating the "dead spot" commonly associated with lifted TJs. The system is a crossover design and is much beefier than the stock setup. Noticeable improvements in the overall crispness were another result. The kit features a 4130 chromoly drag link and tie rod for ultimate durability. Also included is a trick steering stabilizer using rod-end-style joints, which eliminate steering preload commonly found on stabilizers with rubber bushings. This kit is a 100-percent bolt-on for all TJ Dana 30/44 front axles with or without ABS sensors. We loved the feel of this kit in all scenarios of driving.

PhotosView SlideshowOur initial testdrive revealed the J-Spec front springs were a little firm on our four-banger Jeep. We anticipated this because JKS designed the coils for the heavier six-cylinder engine. To compensate for the weight difference (and to improve the Jeep's trail functions), we installed an ARB front winch bumper and a Ramsey 8,000-pound electric winch. These additions increased the weight over the front springs, proving to be the perfect solution. Once installed, the Jeep felt perfectly balanced and the testing continued.

Wrapping up our six-month evaluation over a variety of different terrains, we had nothing but good things to say about the J-Spec Suspension system and the U-Turn steering upgrade. The Jeep improved big-time on the road and in the dirt, in both ride quality and articulation. This assured us that the J-Spec system was the real deal. It became obvious just how much all those little extra features contribute to the system's overall performance. This is one of the those times when the expression "the whole is greater than the sum of its parts" certainly applies. Everything from washboard to boulders confirmed our suspicions that JKS really did their homework before releasing this new system. After several thousand highway miles, we didn't hear any of the typical squeaks and rattles found with other less-expensive kits we've tested. The ride seemed to get even better as the springs broke in. The slightly larger tires had only a minimal effect on power and fuel consumption. The owner does plan to swap in a stroked 4.0L soon. Once he does, we suspect a set of 33s will follow suit. Lucky for him, the 4 additional inches of clearance will accommodate these without issue. For now, however, this Jeep is ready to rock.

PhotosView Slideshow

PhotosView Slideshow