John Cappa

Former Editor, Four Wheeler

John Cappa

Former Editor, Four Wheeler

Xterra IFS Locker

I have a ’14 Nissan Xterra Pro-4X that comes with an electric rear locker. I have lifted it 3 inches, added rock sliders, and replaced the front bumper with a winch bumper and a 12,000-pound winch. I also added a new front skidplate under the engine oil pan, which also protects the front differential. What are your thoughts on adding an ARB front locker or is there an electric locker you can put in the front differential?

I have heard stories about a front locker causing possible front axle or CV joint problems on this style of front-drive system. Owners say I should upgrade to Titan components if I want to lock the frontend. It's too bad these vehicles don't have front locking hubs. This would be a lot easier because I could simply use most any limited-slip-type unit, which would be a little more forgiving on the axles and CV joints. Any ideas?

Ed Mundy

Chino Hills, CA

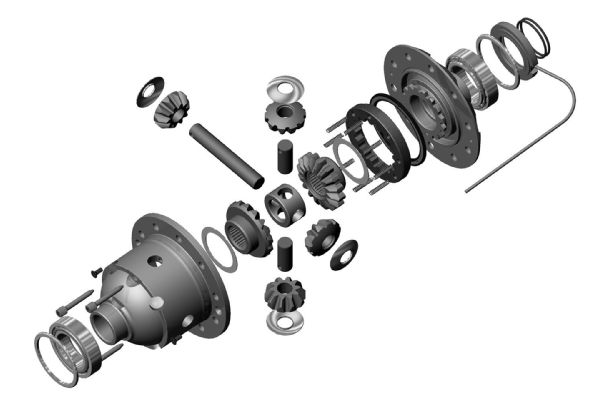

Unfortunately, the ARB (arbusa.com) Air Locker is the only locking differential I know of that is available for the ’05-’15 Xterra IFS front axle assembly. Factory IFS systems are generally a little more delicate and they will take less abuse than a comparable solid front axle system. There is reason for some concern with the use of a front locker in an IFS application. The steering components, CV shafts, and the ring-and-pinion may not be up for the increased traction. However, if used sanely, an ARB front locker in your Xterra can be used successfully in conjunction with the factory rear selectable locker. You should leave the front locker unlocked almost all of the time and only lock it when needed. You’ll want to avoid throttle hopping the vehicle up climbs or ledges. The hopping can cause parts to fail, regardless of what vehicle you are driving. Also, avoid undercut ledges. These are notorious for damaging front axle components. Overloading your Xterra could also lead to premature frontend failure. Keep the vehicle as light as possible and the components will live a much longer life with a locker.

Constipated Cat

I have a ’06 Jeep TJ with a 4.0L inline-six and automatic transmission. It seems to have no power when pulling a hill. It downshifts real hard, and when it does, the rpm drops and so does my speed. I have a check engine code of P0421, which is the catalyst. I'm wondering about just cutting the cat out completely to see if that helps.

James Moseley

Via email

A catalytic converter is used to clean up the exhaust emissions on gas burning engines. Earlier two-way catalytic converters are used to combine oxygen with carbon monoxide (CO) and unburned hydrocarbons (HC) to produce carbon dioxide (CO2) and water (H2O). In 1981, the two-way converters were replaced by three-way converters that also reduce nitrogen oxides (NOx). Higher-mileage vehicles often have catalytic converter issues. The insides of the catalytic converter can become damaged if the converter is dented or banged around, if there is an overly rich fuel condition, if the engine is worn and allows oil to blow by the cylinder rings or valve seats, or if leaded aviation or race fuel is used. Sometimes the converter is just worn out and needs to be replaced. If too much fuel, oil, or the incorrect fuel is pushed through the converter, the honeycomb monolith inside of the steel case can get so hot that it melts. Inadvertently banging on or denting the converter can cause the monolith to break apart. Once either of these scenarios happens, the monolith bits can get turned sideways and block the exhaust path, kind of like an exhaust brake. A blocked exhaust causes the situation you are experiencing. The more you try to rev the engine, the more air it tries to move. The blocked exhaust causes the motor to struggle. Higher rpm will appear to make less power. In a pinch, I have seen people remove the catalytic converter and knock the bits out of the steel shell. I have also seen one owner cut a large hole in the converter, temporarily bypassing the rest of the exhaust. You have to be careful if you have to go this route, as you don’t want the hot exhaust directed at fuel lines, brake lines, wiring, or the transmission. It’s only a temporary solution to get you home where you should replace the catalytic converter.

Longmire Bronco

This may seem like a strange request, but I'm sure you've had stranger. I have been watching the show Longmire for some time now and have also looked at the website for Longmire Days in Buffalo, Wyoming. I’m interested in the Ford Bronco that is used in the show. Do you have or could you get any info on the vehicles used in the show?

Also, on the webpage for the 2014 Longmire Days there are a couple of photos of a white Bronco with a police-type door light. On the tailgate is a Sheriff Interceptor badge. Did Ford make a Bronco as a Sheriff Interceptor or was this a movie car? In any case, could you connect me with someone who has knowledge of these Broncos? I like to have or build one to take to old car and police car shows.

Robert Stolt

Middlesex, NJ

The Ford Bronco in question appears to be a ’94-’96 model. It has an airbag and a different steering wheel than the non-airbag Broncos. Unfortunately, Ford never offered a Sheriff Interceptor Bronco. Interestingly, the naming appears to be stolen straight from the Mad Max Police Interceptor vehicle. However, Ford has supplied Broncos for many different real-life police and other government agencies. The Border Patrol in California had hundreds of them. Many of the early models that were really abused ended up with bent frames. This was easy to spot. The fender to door gap would be much wider at the bottom than on the top of the fender, which sometimes actually came in contact with the doors on the really bent Broncos.

Anyway, there are many different companies in Los Angeles that specialize in building movie and TV show cars. These cars can range from one-off creations like the Armadillo in Armageddon to the relatively mild Ford Bronco of Longmire. I’m not sure who built the Longmire Bronco, but it should be relatively easy for the average person to replicate. Most paint and body shops should be able to convert an ordinary ’94-’96 Ford Bronco into a Sheriff Interceptor. Collect as many detailed images of the Bronco as possible and give them to the reputable auto body shop when you drop off your Bronco. Custom Sheriff Interceptor badges can be purchased from companies like Billet Badges (billetbadges.com).

Classic 4x4 Conversion

I recently acquired a classic ’66 Chevy 3/4-ton pickup from my uncle (amazing how I use the word acquired, yet I still had to pay him for it). It's a two-wheel-drive, and I’m very interested in converting it into a 4x4. It was originally equipped with the HO72 rear axle, but years ago he swapped that out and installed a Dana 44 frontend and a 14-bolt rearend from an ’89 Suburban. Both axles have 4.10 gears. The front suspension was upgraded to leaf springs. I don’t know why he never finished converting it to a 4x4. Do you have any tips as to how to go about doing a low-budget conversion? I want it to be a reliable, street-worthy, and definitely off-road–worthy rig. Currently, the truck is equipped with a Chevy 350ci V-8 backed by an SM465 four-speed manual transmission. I also want to install an upgraded transmission. This one is pretty worn out. It grinds in almost all the gears. Any and all suggestions would be greatly appreciated.

David J. Edwards

Via email

The good news is that the most difficult and expensive part of converting a two-wheel-drive truck to a 4x4 has already been done for you, as long as it was done properly. The SM465 is actually a very durable transmission. Like any drivetrain component, it can wear out. If you wanted to keep and rebuild the SM465, you could have a 4x4 output shaft and factory adapter installed. This would allow you to bolt up a GM NP205 transfer case. You would have to install the factory transfer case shifter and cut a hole in the floor, or go with an aftermarket shifter. Another option is to switch over to an automatic. You could keep an eye out for a transmission and transfer case assembly from almost any 4x4 GM truck up to ’87 and Blazer or Suburban to ’91. The transmissions used in these 4x4s include the SM465 four-speed manual, the venerable TH350 three-speed automatic, the extremely heavy-duty TH400 three-speed automatic, and the light-duty 700R4 four-speed automatic. Any of these transmissions will bolt up to your engine. However, you will need to design a crossmember for the transmission mount. Each transmission requires slightly different wiring, and the automatics will need to be fit with kick-down hardware, as well as a transmission cooler. New front and rear driveshafts will need to be built no matter which way you go. The later electronically controlled 4L60E and 4L80E four-speed automatics are also an option. However, they are substantially more complex and expensive to adapt. In addition to the transmission, you will need an aftermarket standalone wiring harness to make them work in your older 4x4.

Offroad Design (offroaddesign.com) specializes in modifying fullsize trucks like yours and offers adapters, transmissions, transfer cases, shifter assemblies, and complete packages that can be used to simplify and finish up your 4x4 conversion.

If you want to stick with a manual transmission but want an Overdrive gear, you can swap in an NV4500 five-speed manual. This transmission is available with a factory bellhousing that will bolt to your engine, but it never came from the factory with a passenger-drop transfer case, so you’ll need an adapter. This is a much more expensive route than the SM465, TH350, or TH400 options mentioned above.

Cost-Effective JK 3.8L Swap

I’m a long-time reader and love the magazine. I have a question that may have already been answered. In most ways my rig resembles the early version of your project Con Artist. What would it take to swap out the anemic old 3.8L oil-burning minivan engine in my ’07 JK Rubicon and put in a newer 3.6L Pentastar with the auto tranny? My original motor has 135,000 miles on it, and it's started a smoking habit at every traffic light. I don't want to overpower the vehicle because I am giving it to a brand-new driver early next year. My Jeep has been packing on the pounds because I used to live right next to a major aftermarket supplier in West Chester, Pennsylvania. I know everybody loves to swap in Hemi engines, but I love my son more, and I don't want to see him wrapped around a tree with more than 350 hp. I'm really interested in just giving my favorite ride ever some new life, improved fuel mileage, and long-term livability by sticking with nearly stock engine and transmission components.

Joe

Via email

Unfortunately, swapping a ’12-current Jeep Wrangler 3.6L Pentastar V-6 in place of a ’07-’11 JK 3.8L V-6 is not cost effective. The swap would ultimately be about the same as swapping in a Hemi V-8 or even an older 2.8L EcoDiesel. For the amount of money you would have invested in a swap like this, you would be money ahead if you simply sold your Jeep and bought a ’12-current Jeep JK with the 3.6L Pentastar already in it. If you really like the Jeep as it sits, your most cost-effective option is to simply replace your worn-out 3.8L with a new one or a low-mileage engine from the wrecking yard.

TJ Lug Pattern Conversion

I currently drive a ’06 Jeep Rubicon Unlimited. It has the stock Rubicon axletubes, but I’m running Alloy USA axleshafts. In addition, I am working to install a long-arm suspension. I am looking to move from the stock 5-on-4.5 hub assemblies up front to a 5-on-5 lug pattern. My thinking is that the newer JKs are 5-on-5 so the swap will allow more future tire options. This is especially true with 17-inch wheels. The Alloy USA rear axleshafts are already drilled to support either 5-on-4.5 or 5-on-5, so I am only looking at converting the front axle. Is there a good strong hub assembly that would allow this conversion? I don’t want to run wheel spacers.

John Harvin

Fredericksburg, VA

Switching to the 5-on-5 lug pattern really isn’t necessary. There are plenty of 17-inch wheels available for the 5-on-4.5 lug pattern. However, the main problem I see with your idea is that the rear Alloy USA axleshafts you have are likely drilled for 5-on-4.5 and the older Jeep/Ford 5-on-5.5, not the JK 5-on-5. Measuring 5-lug patterns can be confusing. You need to measure from the outer edge of one stud to the center of the furthest stud for a correct lug-pattern measurement. Now, if you want to convert to the 5-on-5.5 lug pattern up front, you have some options. There are wheel spacer adapters that will convert your 5-on-4.5 front hub to 5-on-5.5, but they will increase your overall front track width by 2 1/2 inches, which is not a concern in most cases. Companies like Spidertrax (spidertrax.com) offer quality, U.S.-made, affordable wheel spacers and adapters for many different applications. Since you don’t want to go this route, you’ll have to spend significantly more money. Rusty’s Off-Road (rustysoffroad.com) offers a complete brake and locking hub conversion kit that will get you the larger 5-on-5.5 lug pattern you are looking for. It comes complete with hubs, rotors, spindles, locking hubs, stub shafts, wheel bearings, and more. It’s also about 15-times more expensive than a set of wheel spacers. The biggest advantage is that you end up with front locking hubs, which can slightly improve fuel economy and reduce front axle wear when driving on-road. Solid Axle (solidaxle.com) offers a similar kit under the SpynTec name.

It might be possible to have your unit bearings and rotors drilled with the larger bolt pattern, although I don’t think there is enough material there to do that. I’m a little surprised that none of the aftermarket manufacturers have offered a TJ, XJ, ZJ, MJ, or YJ front unit bearing assembly and rotors with the dual-lug pattern. I suppose most of the people switching the rear to 5-on-5.5 have swapped in an older traditional Dana 44 front axle and need to match the rear to the new front instead.

High Octane JK

Thank you for the great magazine. I have a ’15 Jeep JK. Is there is any performance advantage to using 89 octane fuel in my Wrangler?

David

Via email

There is often a lot of confusion about which grade fuel is best for your engine. You will typically find three grades of unleaded fuel at the pump. These include 85-87 octane, 89 octane, and 91-93 octane fuels. Without diving too deep into fuel chemistry, a higher octane rating means that the fuel is more stable. Fuel that is more stable is more difficult to ignite, which is good for high-compression engines. Low-grade fuel in a high-compression engine can cause detonation, which can damage the engine. Detonation is simply short for predetonation, meaning that the fuel ignites before the ignition fires. A higher-octane fuel is less likely to predetonate during the compression stroke in a high-compression engine. If an engine is experiencing detonation, it can usually be heard by the human ear. It will generally only happen when the engine is under load. Extreme cases of detonation sound like a grass jar of marbles being shaken. Some aftermarket modifications such as superchargers and turbos require the use of higher octane fuels because of the increased cylinder pressures.

Ultimately, the best way to avoid detonation and to ensure your engine lives a long happy life is to use the fuel grade recommended by the manufacturer. Most mass-production engines, including the 3.6L Pentastar V-6 in your Jeep JK Wrangler, require 87 octane. Anything greater than the recommended 87 octane rating is simply a waste of money. Interestingly enough, some modern computer-controlled engines that do require higher octane fuel are advanced enough that they can run just fine on 87 octane fuel. However, when or if the engine sensors indicate there is detonation, the computer will retard the timing, which will reduce power slightly.