John Cappa

Former Editor, Four Wheeler

John Cappa

Former Editor, Four Wheeler

JK 3.8L to 3.6L Swap

I have a two-door ’07 JK Wrangler with the oil-burning/sucking 3.8L V-6 engine. I have previously considered selling or trading the Jeep for a ’12-’15 four-door with the 3.6L Pentastar engine, but those prices are outrageous! Is it possible to plop a newer 3.6L into my 3.8L rig? And, if so, what else would need to be changed? Computer? Wiring harness? Blood sample? Approval from congress? You get the idea.

Chris Beasley

Via email

Anything is possible, as long as you have the funds to make it happen. Unfortunately, a swap like this really isn’t a cost effective option, mostly because of the engine price and electronics involved. You’ll end up dumping a ton of money into an older JK that’s still an older V-6 Jeep when you are done. A V-8 swap would likely be less expensive because it’s more common and the parts are readily available to make the conversion. In my opinion, you have two viable options if you want to stick with a V-6 engine. The simplest solution is to save your pennies and trade the oil-burner in on a newer model JK with the 3.6L. The less expensive route is to simply find a wrecking-yard 3.8L with low miles and replace your engine. You might also try to contact shops that do JK V-8 engine conversions—they often have several good used V-6 engines laying around. Ultimately, it sounds as though you would rather have a four-door JK anyway, so the trade-in route likely makes more sense.

Space Up

Years ago, Jp magazine modified a WJ Grand Cherokee with a Daystar budget boost and shocks. Do you remember much about that Jeep? How did it ride? I’m torn between a Fat Bob’s Garage 3-inch lift and a budget boost spacer lift with Bilstein shocks. The old lady is scared to death to drive the WJ. She’s used to little compact cars. I don’t mind the Jeep, but I want a little more stability and some more capability off-road. I’d like to firm up the ride and lift it without breaking the bank. The current coil springs seem to be in good shape and have not sagged. I plan to eventually get a TJ Wrangler or maybe a JK Unlimited.

Mark Edward Pittman Jr.

Via facebook.com/JohnCappa4x4

You make an important point, it’s always a good idea to make sure that your coil springs are in good shape and not totally sagged-out before installing coil spacers on your Jeep. This will ensure that you get the actual tire clearance that you might be trying to achieve. Because the spacer kits use your factory coil springs, the ride won’t change all that much from stock. If you are looking for a plush ride, it’s hard to beat the factory coils, although your shocks are likely pretty shot if they are original. Worn shocks could cause the WJ to wallow and sway more than normal through corners and over larger dips in the road. Going with the spacers and shocks is a solid plan, even more so considering that you eventually plan to move into a different Jeep. There is no point in spending money on a vehicle for the next owner to enjoy, right? Ultimately, if a soft ride and saving money most important, go with the spacers and quality shocks. If you plan to drive more aggressively off-road or load the Jeep up with gear regularly, you might want to consider going with a lift kit that includes heavier coils than stock.

Saggy Spring Solution

I have a ’73 Jeep J-truck that I put ’73-’87 GM 4x4 truck leaf springs on. The suspension has started to sag on the passenger side. I took some measurements, and it seems to be the front springs. They also look bent. I believe the springs I have are Superlift. They survived a good six-plus years. What brand do you recommend? I’m just curious if there’s really a difference between all the different companies.

Daniel Chavez

Via facebook.com/JohnCappa4x4

Most of the modern aftermarket leaf spring packs available today are usually of a pretty high quality. However, the minor differences that go mostly unnoticed to the untrained eye can make a leaf spring more off-road friendly. First and foremost, you should choose the springs based on the application. If you plan to regularly haul a bed-load of bricks, then you have probably accepted that you will have to endure a pretty rough ride when the truck is empty. And likewise, if you have decided to install soft-riding compliant leaf packs, then you have likely accepted that the suspension will sag more when hauling a heavy load. Making modifications to the suspension always requires some kind of compromise. Fortunately, you have installed leaf springs from an application that enjoys lots of aftermarket support, certainly more than the ’63-’73 J-truck post-mount suspension.

When choosing leaf springs for an off-road rig, there are several things to look for. I look for a leaf pack with many thin leaves, rather than fewer thick leaves. The multiple thinner leaves will typically ride softer and maintain their lift and ride height better than a leaf pack with fewer thick leaves. Also, look at the end of each individual leaf. Leaf packs that have leaves with tapered and rounded ends will ride softer than those that have individual leaves with straight, square-cut ends. Plastic inserts at the spring tips also help improve the ride by allowing the leaves to slide past each other as the spring compresses and droops. In some cases, you can completely remove the thick bottom load leaf if you don’t plan on hauling heavy loads. Another feature to look for, albeit less common, is military-wrapped spring eyes. This is where the second leaf in the pack comes up to and wraps around the main leaf at the spring eyes. This helps control axle wrap and keeps the assembly together in the event that the main spring eye snaps off under heavy use or abuse.

Many of the aftermarket leaf spring companies produce both a heavy-duty and softer-riding spring options. Choose the springs that make sense for your application. Owners of Jeep with overly heavy engines may want to steer into heavy-duty leaf packs up front. It might take a bit of research, but most of the aftermarket suspension companies publish the spring rates of the leaf packs that are offered. You can compare spring rates from the different brands to find the leaf pack that best suits your application. Lift companies such as BDS Suspension (bds-suspension.com) offer a lifetime free-replacement warranty on parts, so that’s something to consider as well.

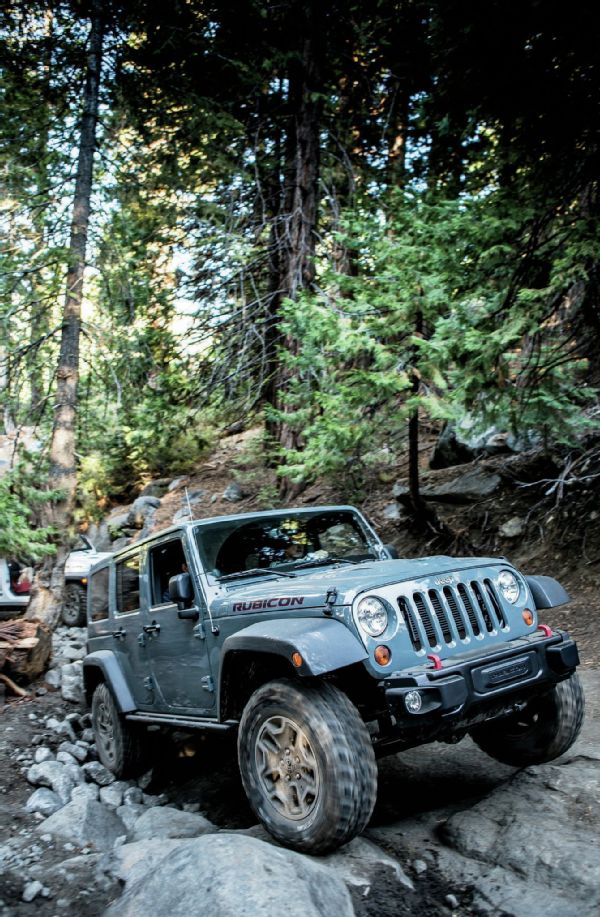

Rubi-Gone

I’ve always wanted to research and compare buying a new or used Rubicon versus buying a new or used base JK. Would you come out ahead by buying a base model and building it with an aftermarket transfer case, axle assemblies, lockers, and so on? You could also offset some of the cost by selling the stock parts and end up with a rig superior to a Rubicon. The idea for this came from personal experience, but I started with a Rubicon and then sold off the stock parts to help fund the new ones. This was not the most efficient way of doing it as it defeated the whole purpose of buying a Rubicon in the first place.

Dennis

Via facebook.com/JohnCappa4x4

That’s the rub: The Rubicon model is a great off-road package as-is from the factory. However, when you start bolting on aftermarket parts, at what point is it no longer a viable platform to start with? Personally, I think the Rubicon model caters too much to a specific purpose. If you like slow and technical driving, then the Rubicon works awesome. However, if you also enjoy desert two-track, sand dunes, deep snow, sand, and mud, then the Rubicon starts to lose its luster. In many of these situations, the 4:1 low range in the transfer case is simply too low. The top speed on the Rubicon in low range is about 25 mph. In many cases, this just doesn’t cut it for dune, mud, and snow use because it’s impossible to build any real wheel speed. I’ve found that the available JK engines don’t make enough power for me to efficiently use high-range in some of these situations. I’ve asked the engineers at Jeep for a three-speed transfer case for years, but I’m sure the cost at the OE level keeps it from being a possibility. I can still dream though.

Anyway, to your point, when the JK first came out, it was available in a two-wheel-drive model. Many people that had plans to simply rip the Jeep apart went this route. That way they could swap the axles out and install whatever transfer case they wanted. All they really needed was a frame, engine, transmission, and body to start with.

Now, the real problem is that most people don’t make all their modifications at once. It’s usually a slow process that takes years. These owners often want the Rubicon capability right out of the box. But yes, if the plan is to go with 37-inch or larger tires right away, then it makes no sense to start with a Rubicon. Ultimately, the Rubicon is generally a good deal if you prefer technical driving and plan to keep your maximum tire diameter at less than 35 inches or maybe 37 inches if you baby it off-road.

Home-Job Rock Sliders

I have a question about rock sliders: What is the best way to fabricate and attach rocker guards to a Jeep? Should they bolt or weld to the frame. I would like to make some for my Jeep TJ. Do you guys have a story I can look up or do you have any tips?

Alex Spafford

Via facebook.com/jpmag

There are several ways to attach rocker guards to a Jeep. Which method is best really depends on how you plan to use the Jeep and the specific Jeep model you are working with. On a TJ, it’s a good idea to incorporate the rocker guards into the body mounts and the side of the body tub for ground clearance reasons. The easiest way to do this is to make them so they bolt on. I would recommend using 3⁄16-inch steel plate since you are essentially working with a single 90-degree angle on the side of the Jeep. You can add a tube for extra protection under the door. There are several aftermarket rocker guards available that you can borrow ideas from. Now if you want to build your rocker guards out of tubing, know that you are sacrificing some ground clearance. Tubular rocker guards are usually most effective when welded directly to the frame with large gusseted 3⁄16-inch-thick mounting feet. This helps spread the load when the rockers come into contact with trail obstacles. As for the type of tubing to use, I would recommend 13⁄4-inch, 0.120-wall DOM for the main tubes and 11⁄2-inch, 0.120-wall DOM for any additional tubes. The DOM tubing is significantly stronger than HREW tubing and less likely to crush under load. DOM is also less likely to get gouged by rocks, meaning your Jeep will slide over them more easily. If you are interested in the tubular rocker guards, you can find the story I wrote about the topic on a different model Jeep here: http://bit.ly/1Mb3LKa. However, you won’t want to weld the rockers to the body of your TJ like we did on our FSJ.

Track Bar Tech

Well, I’ve been checking the online forums trying to figure out the best way to do something. As usual, I’m left feeling more confused than I was when I started, which leads me to you. So this should be a nice simple question for you, right? For a 4-inch lift on a ’98 TJ, what is the better route: an adjustable track bar or a relocation bracket?

Josh Anderson

Via email

The track bar locates the axle laterally under the front of your Jeep. If you lift the Jeep, the axle moves to the driver side. As the suspension compresses, the axle cycles to the passenger side. With lifts over 2 inches, you need some sort of track bar correction. Also, if the track bar and steering geometry on your TJ get out of whack, you will have significant bumpsteer both on- and off-road. This will make the Jeep twitchy and difficult to drive, especially over bumpy surfaces. The track bar and steering draglink work as a system and need to be modified as such. If you modify one, you generally need to modify the other.

There are two ways to easily correct the track bar geometry on your TJ but only one of them will work on your Jeep. Which one you need to use will depend on the other modifications you have made. The end goal is to make sure that the track bar and draglink are similar in length and rest at the same angle, which eliminates bumpsteer. If your Jeep has an aftermarket dropped pitman steering arm, you’ll want to use a track bar drop bracket to match the track bar angle to the draglink angle. If your Jeep uses the stock pitman arm, then you can use an adjustable track bar to recenter the axle. However, using the stock pitman arm at 4 inches of lift will generally cause the stock tie-rod ends to bind when the suspension droops, accelerating wear and potentially causing a dangerous steering situation. So if your suspension kit utilizes the stock pitman arm with 4-plus inches of lift, I would recommend upgrading to the Currie Enterprises (currieenterprises.com) Currectlync heavy-duty draglink and tie rod assembly. The new tie-rod ends allow for more movement at this lift height. The Currie Currectlync tie rods are made from massive 11⁄4-inch-diameter forged solid alloy steel. They are a lot stronger and safer than stock.

Which JK Lift Kit?

I have a four-door JK that is my daily driver. It sees some light off-roading and rolls on 35-inch tires. I was hoping you could give me some info on which 21⁄2-inch spring lift is the best quality. Is the Rubicon Express or the TeraFlex kit better as far as spring fade and controlling the extra weight of heavy aftermarket bumpers?

Jarvis Yrtlahc

Via facebook.com/jpmag

Unfortunately, it’s nearly impossible for me to pick a lift kit for you and your preferences. Many of the 21⁄2-inch kits are very similar. Both of the kits you have selected are quality lift kits. If you really want the best lift kit, buy the most expensive one that comes with the most features. As with anything in life, you generally get what you pay for. The same is true of lift kits in most cases. If your bumpers are loaded down with gear or are heavier than most aftermarket bumpers, you can look into the spring rates of the coils from the lift manufacturers you are considering. Some companies offer both a light and heavy spring rate because Jeep JKs can be built in so many different ways. The total weight can vary from Jeep to Jeep up to more than 2,000 pounds depending on how they are accessorized.

Write Us!

Got a tech question you’re just itching to get answered? Send it on in to Jp Magazine, Your Jeep, 831 S. Douglas St., El Segundo, CA 90245, or e-mail it to jpeditor@jpmagazine.com.